14 - 35

Chapter 14 Common Functions

(4) I/O signals of slave axis

(a) Input signal

[QD77MS2]

Only the error detection signal [X8, X9] is valid. And only the servo error

detection is valid. (The control of slave axis is not influenced even if the

error other than servo error has been occurred.)

[QD77MS4]

Only the error detection signal [X8 to XB] is valid. And only the servo

error detection is valid. (The control of slave axis is not influenced even

if the error other than servo error has been occurred.)

[QD77MS16]

All signals cannot be used. The error detection signal turns ON "Error

detection" ([Md.31]

Status: b13).

(b) Output signal

All output signals of slave axis cannot be used.

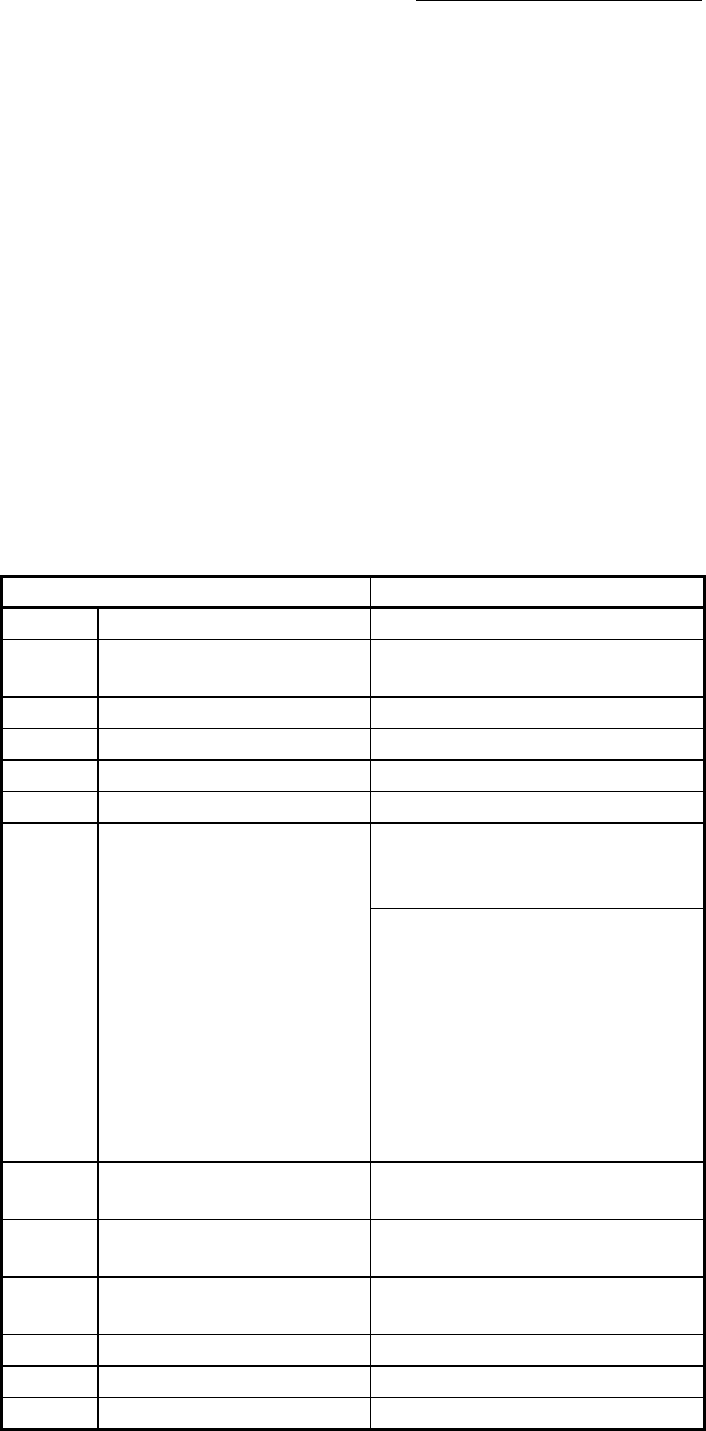

(5) Data used for positioning control of slave axis

(a) Only the following axis monitor data are valid in slave axis.

Item Remark

[Md.23]

Axis error No. Valid for only servo error detection.

[Md.35]

Torque limit stored value/forward

torque limit stored value

—

[Md.102]

Deviation counter value —

[Md.103]

Motor rotation speed —

[Md.104]

Motor current value —

[Md.107]

Parameter error No. —

[Md.108]

Servo status

The following bit is valid.

• b0: Zero point pass

(Execute OPR to the master axis.)

The following bits are valid.

• b0: READY ON

• b1: Servo ON

• b7: Servo alarm

(Note): The slave axis is always

controlled in torque control mode,

"control mode (high-order buffer

memory address: b2, b3)" is set

to torque control mode (0, 1).

[Md.109]

Regenerative load ratio/Optional

data monitor output 1

—

[Md.110]

Effective load torque/Optional

data monitor output 2

—

[Md.111]

Peak torque ratio/Optional data

monitor output 3

—

[Md.112]

Optional data monitor output 4 —

[Md.114]

Servo alarm —

[Md.120]

Reverse torque limit stored value —