13 - 2

Chapter 13 Control Sub Functions

13.1 Outline of sub functions

"Sub functions" are functions that compensate, limit, add functions, etc., to the control

when the main functions are executed. These sub functions are executed by

parameter settings, operation from GX Works2, sub function sequence programs, etc.

13.1.1 Outline of sub functions

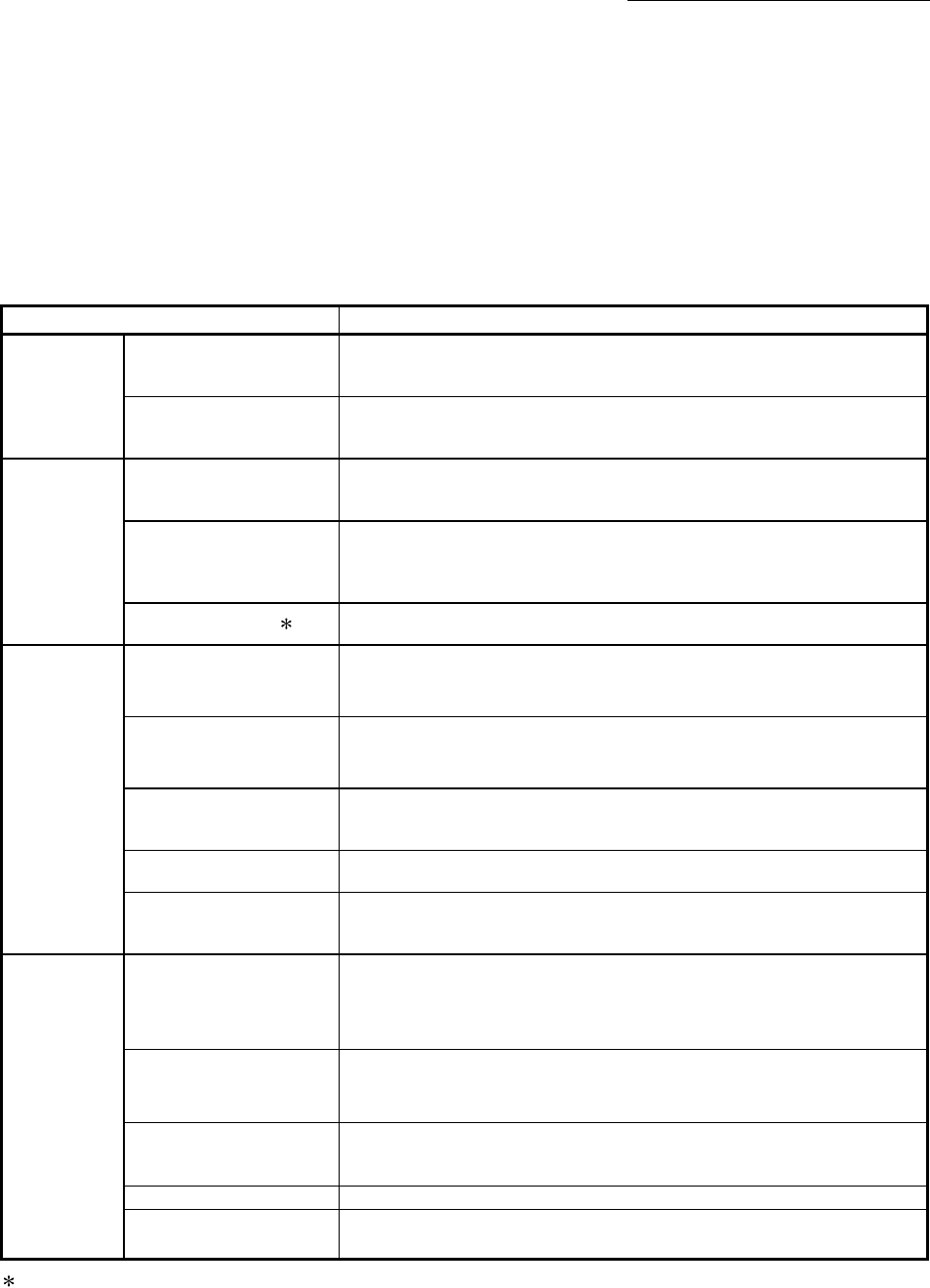

The following table shows the types of sub functions available.

Sub function Details

Functions

characteristic

to machine

OPR

OPR retry function

This function retries the OPR with the upper/lower limit switches during

machine OPR. This allows machine OPR to be carried out even if the axis is

not returned to before the near-point dog with JOG operation, etc.

OP shift function

After returning to the machine OP, this function offsets the position by the

designated distance from the machine OP position and sets that position as

the OP address.

Functions that

compensate

control

Backlash compensation

function

This function compensates the mechanical backlash. Feed command

equivalent to the set backlash amount are output each time the movement

direction changes.

Electronic gear function

By setting the movement amount per pulse, this function can freely change

the machine movement amount per commanded pulse.

When the movement amount per pulse is set, a flexible positioning system

that matches the machine system can be structured.

Near pass function 1

This function suppresses the machine vibration when the positioning data is

switched during continuous path control in the interpolation control.

Functions that

limit control

Speed limit function

If the command speed exceeds "[Pr.8] Speed limit value" during control, this

function limits the commanded speed to within the "[Pr.8] Speed limit value"

setting range.

Torque limit function

If the torque generated by the servomotor exceeds "[Pr.17] Torque limit

setting value" during control, this function limits the generated torque to

within the "[Pr.17] Torque limit setting value" setting range.

Software stroke limit

function

If a command outside of the upper/lower limit stroke limit setting range, set in

the parameters, is issued, this function will not execute positioning for that

command.

Hardware stroke limit

function

This function carries out deceleration stop with the hardware stroke limit

switch.

Forced stop function

This function is stopped the all axes of the servo amplifier when the forced

stop input signal of the Simple Motion module external input connection

connector is turned ON.

Functions that

change control

details

Speed change function

This function changes the speed during positioning.

Set the changed speed in the speed change buffer memory ([Cd.14] New

speed value), and change the speed with the speed change request ([Cd.15]

Speed change request).

Override function

This function changes the speed within a percentage of 1 to 300% during

positioning. This is executed using "[Cd.13] Positioning operation speed

override".

Acceleration/deceleration

time change function

This function changes the acceleration/deceleration time during speed

change. (Functions added to the speed change function and override

function.)

Torque change function This function changes the "torque limit value" during control.

Target position change

function

This function changes the target position during the execution of positioning.

At the same time, this also can change the speed.

1: The near pass function is validated only when the machine of the standard specification carries out the position control

with the continuous path control mode. It cannot be invalidated with parameters.