6 - 71

Chapter 6 Sequence Program Used for Positioning Control

(6) When stopped with interpolation operation, write "1: Restarts" into "[Cd.6]

Restart command" for the reference axis, and then restart.

(7) If the PLC READY signal is changed from OFF to ON while stopped, restarting

is not possible.

If restart is requested, the warning "Restart not possible" (warning code: 104)

will occur.

(8) When the machine OPR and fast OPR is stopped, the error "OPR restart not

possible" (error code: 209) will occur and the positioning cannot restarts.

(9) If any of reference partner axes executes the positioning operation once after

interpolation operation stop, the warning "Restart not possible" (warning code:

104) will occur, and the positioning cannot restarts.

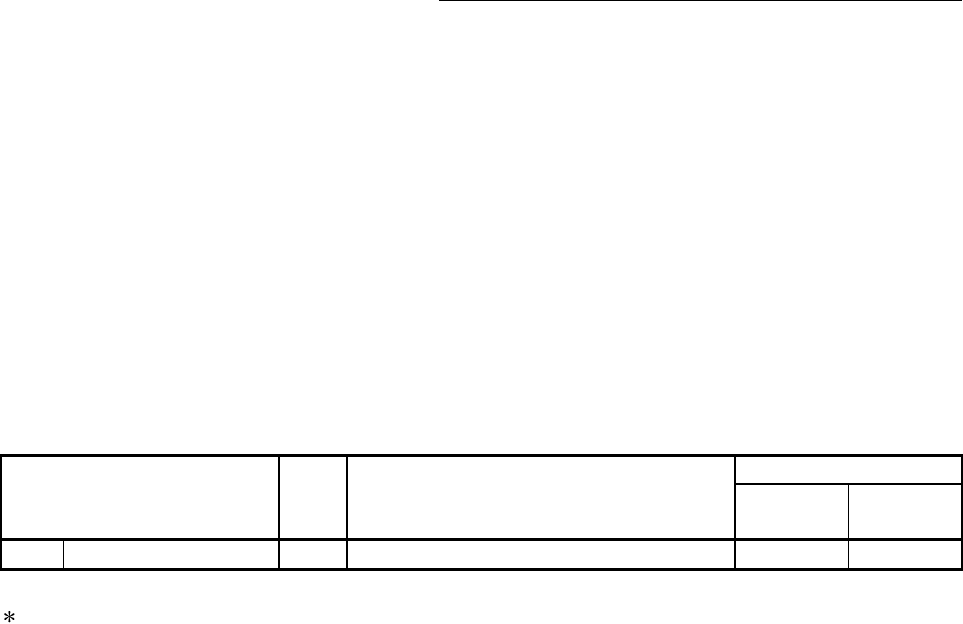

[3] Control data requiring setting

Set the following data to execute restart.

Setting item

Setting

value

Setting details

Buffer memory address

QD77MS2

QD77MS4

QD77MS16

[Cd.6] Restart command 1 Set "1: Restarts". 1503+100n 4303+100n

n: Axis No.-1

: Refer to Section 5.7 "List of control data" for details on the setting details.

[4] Starting conditions

The following conditions must be satisfied when restarting. (Assemble the

required conditions into the sequence program as an interlock.)

(1) Operation state

"[Md.26] Axis operation status" is "1: Stopped".