13 - 77

Chapter 13 Control Sub Functions

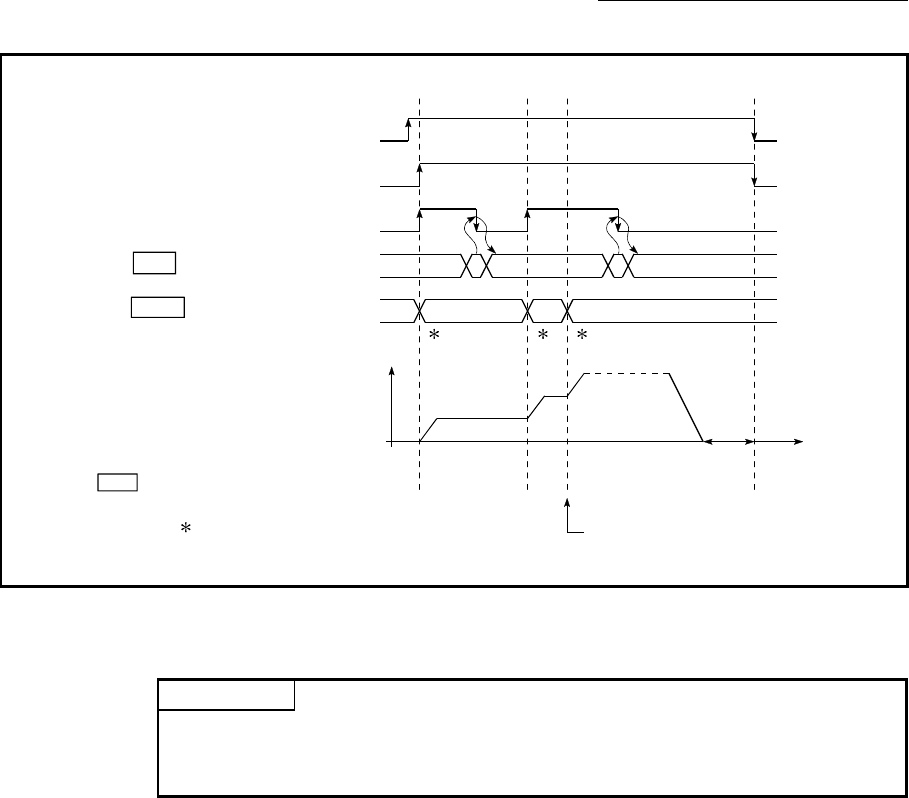

[QD77MS4 operation example]

Da. 1 Operation pattern

Md. 25 Valid M code

Cd. 7 M code OFF request

11 0011

Warning occurs at this timing.

t

m1 m3

m2

V

1

OFF

ON

OFF

OFF

ON

ON

0 1

0

0

Positioning start signal

BUSY signal

M code ON signal

Positioning

1: m1 and m3 indicate set M codes.

[XC, XD, XE, XF]

[Y10, Y11, Y12, Y13]

[X4, X5, X6, X7]

1 1 1

(Note): Refer to Section 3.3 for input/output signal of QD77MS16.

Fig. 13.42 Warning due to an M code ON signal during continuous path control

POINT

If the M code output function is not required, set a "0" in setting item "[Da.10] M

code/Condition data No./Number of LOOP to LEND repetitions" of the positioning

data.

[3] Precautions during control

(1) During interpolation control, the reference axis M code ON signal is turned

ON.

(2) The M code ON signal will not turn ON if "0" is set in "[Da.10] M

code/Condition data No./Number of LOOP to LEND repetitions". (The M

code will not be output, and the previously output value will be held in

"[Md.25] Valid M code".)

(3) If the M code ON signal is ON at the positioning start, the error "M code ON

signal start" (error code: 536) will occur, and the positioning will not start.

(4) If the PLC READY signal [Y0] is turned OFF, the M code ON signal will turn

OFF and "0" will be stored in "[Md.25] Valid M code".

(5) If the positioning operation time is short during continuous path control,

there will not be enough time to turn OFF the M code ON signal, and the

warning "M code ON signal ON" (warning code: 503) may occur. In this

case, set a "0" in the "[Da.10] M code/Condition data No./Number of LOOP

to LEND repetitions" of that section's positioning data to prevent the M

code from being output for avoiding the warning occurrence.

(6) In the AFTER mode during speed control, the M code is not output and the

M code ON signal does not turn ON.

(7) If current value changing where "9003" has been set to "[Cd.3] Positioning

start No." is performed, the M code output function is made invalid.