5 - 6

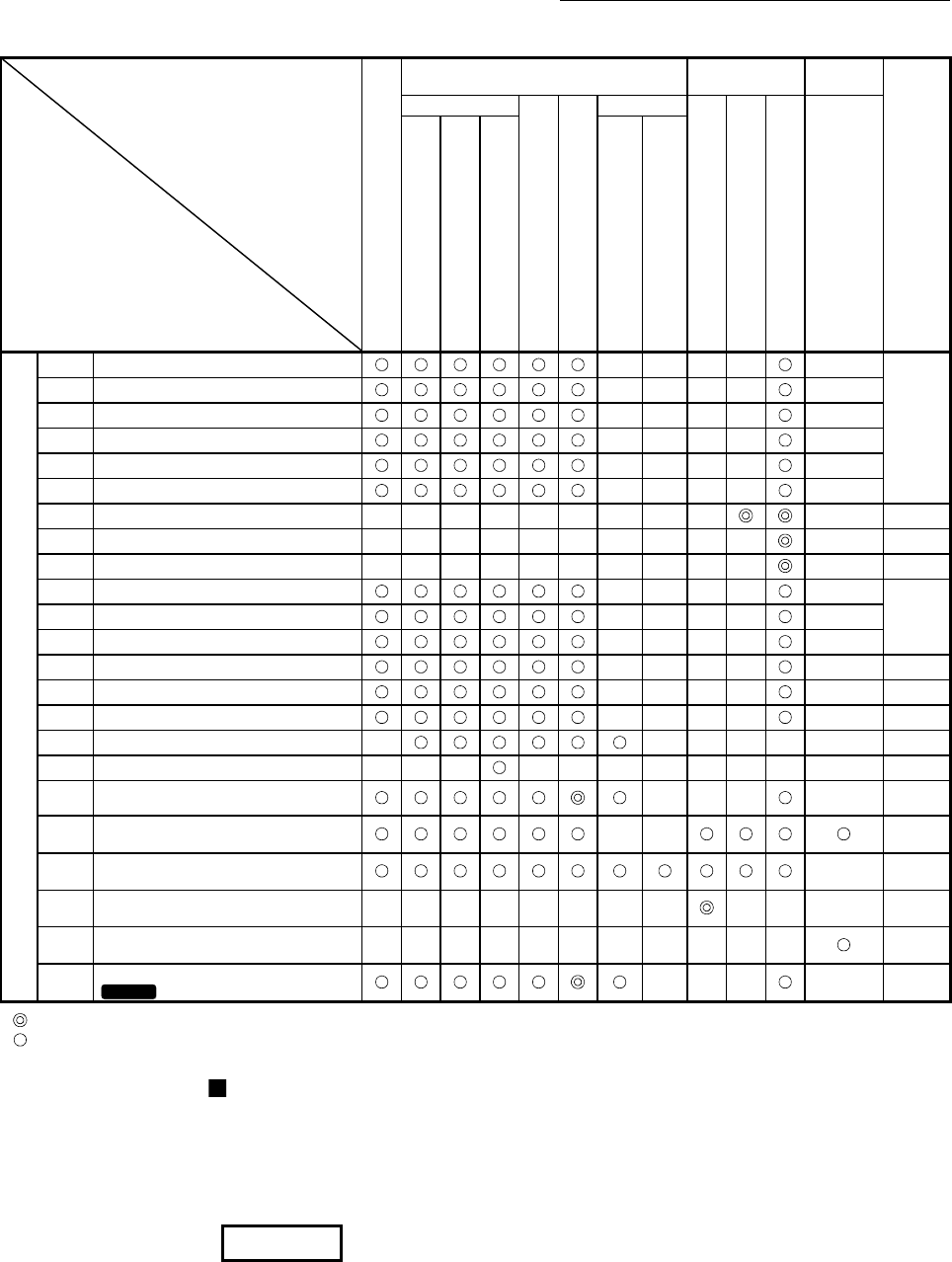

Chapter 5 Data Used for Positioning Control

Control

Positioning parameter

OPR control

Major positioning control Manual control

Expansion

control

Related sub function

Position control

1 to 4 axis speed control

Speed-position or position-speed control

Other control

Manual pulse generator operation

Inching operation

JOG operation

Speed-torque control

1-axis linear control

2/3/4-axis linear interpolation control

1-axis fixed-feed control

2/3/4-axis fixed-feed control

2-axis circular interpolation control

Current value changing

JUMP instruction, NOP instruction,

LOOP to LEND

Detailed parameters 2

[Pr.25]

Acceleration time 1

– – – –

–

13.7.6

[Pr.26]

Acceleration time 2

– – – –

–

[Pr.27] Acceleration time 3 – – – –

–

[Pr.28] Deceleration time 1 – – – –

–

[Pr.29]

Deceleration time 2

– – – –

–

[Pr.30]

Deceleration time 3

– – – –

–

[Pr.31] JOG speed limit value – – – – – – – – –

– 13.4.1

[Pr.32] JOG operation acceleration time selection – – – – – – – – – –

– –

[Pr.33]

JOG operation deceleration time selection – – – – – – – – – –

– –

[Pr.34]

Acceleration/deceleration process selection

– – – –

–

13.7. 6

[Pr.35] S-curve ratio – – – –

–

[Pr.36] Sudden stop deceleration time – – – –

–

[Pr.37]

Stop group 1 sudden stop selection

– – – –

– –

[Pr.38]

Stop group 2 sudden stop selection

– – – –

– –

[Pr.39] Stop group 3 sudden stop selection – – – –

– –

[Pr.40] Positioning complete signal output time – – – – – – –

[Pr.41]

Allowable circular interpolation error width – – –

– – – – – – – – –

[Pr.42]

External command function selection

– – –

–

13.5.1

13.7.2

[Pr.83]

Speed control 10 x multiplier setting for

degree axis

–

–

13.7.10

[Pr.84]

Restart allowable range when servo OFF

to ON

–

5.2.4

[Pr.89]

Manual pulse generator/Incremental

synchronous encoder input type selection

– – – – – – – –

– – –

5.2.4

[Pr.90]

Operation setting for speed-torque control

mode

– – – – – – – – – – –

12.1

[Pr.95]

External command signal selection

QD77MS16

– – –

–

–

: Always set

: Set as required ("–" when not required)

– : Setting not required (The setting value is invalid. When the value is the default value or within the setting range, there is no problem.)

Checking the positioning parameters

[Pr.1] to [Pr.90], [Pr.95] are checked with the following timing.

When the "PLC READY signal [Y0]" output from the PLC CPU to the Simple

Motion module changes from OFF to ON.

When the positioning test of GX Works2 is executed.

REMARK

"High-level positioning control" is carried out in combination with the "major

positioning control".

Refer to the "major positioning control" parameter settings for details on the

parameters required for "high-level positioning control".