9 - 122

Chapter 9 Major Positioning Control

9.2.19 Current value changing

When the current value is changed to a new value, control is carried out in which the

"[Md.20] Current feed value" of the stopped axis is changed to a random address set

by the user. (The "[Md.21] Machine feed value" is not changed when the current value

is changed.)

The two methods for changing the current value are shown below.

[1] Changing to a new current value using the positioning data

[2] Changing to a new current value using the start No. (No. 9003) for a current

value changing

The current value changing using method [1] is used during continuous positioning of

multiple blocks, etc.

[1] Changing to a new current value using the positioning data

In "current value changing" ("[Da.2] Control system" = current value changing),

"[Md.20] Current feed value" is changed to the address set in "[Da.6]

Positioning address/movement amount".

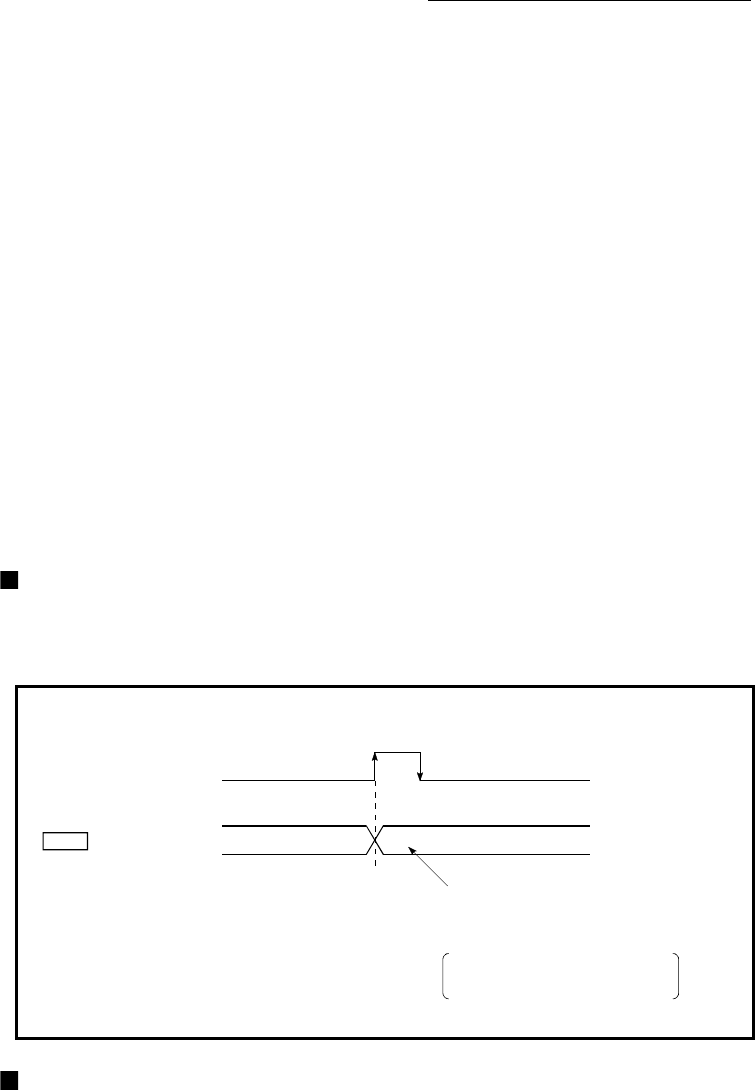

Operation chart

The following chart shows the operation timing for a current value changing. The

"[Md.20] Current feed value" is changed to the value set in "[Da.6] Positioning

address/movement amount" when the positioning start signal turns ON.

[QD77MS4 operation example]

Positioning start signal

Md.20

50000 0

OFF

ON

Current feed value changes to the

positioning address designated by the

positioning data of the current value changing.

The above chart shows an example

when the positioning address is "0".

Current feed value

[Y10, Y11, Y12, Y13]

(Note): Refer to Section 3.3 for input/output signal of QD77MS16.

Restrictions

(1) The error "New current value not possible" (error code: 515) will occur and the

operation cannot start if "continuous path control" is set in "[Da.1] Operation

pattern". ("Continuous path control" cannot be set in current value changing.)

(2) "Current value changing" cannot be set in "[Da.2] Control system" of the

positioning data when "continuous path control" has been set in "[Da.1]

Operation pattern" of the immediately prior positioning data. (For example, if

the operation pattern of positioning data No. 1 is "continuous path control",

"current value changing" cannot be set in positioning data No. 2.) The error

"New current value not possible" (error code: 515) will occur and the machine

will carry out a deceleration stop if this type of setting is carried out.