10 - 6

Chapter 10 High-Level Positioning Control

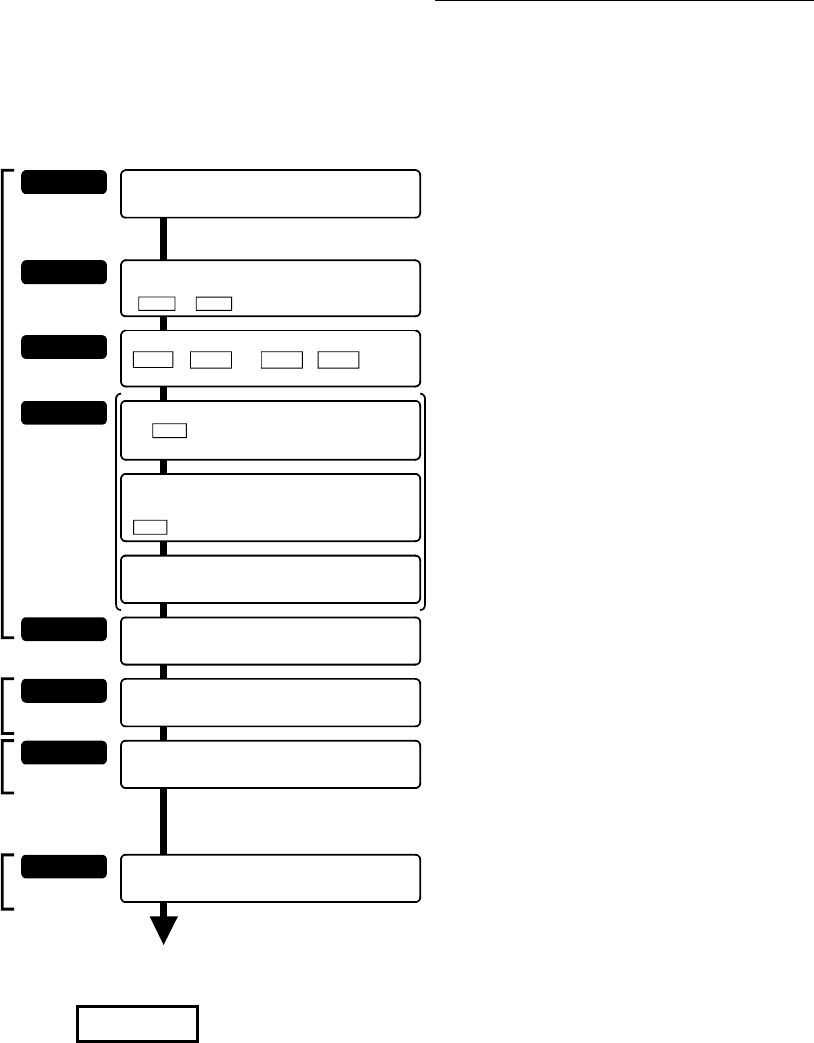

10.2 High-level positioning control execution procedure

High-level positioning control is carried out using the following procedure.

STEP 1

Preparation

Refer to Chapter 9

Carry out the "major positioning control" setting.

"High-level positioning control" executes each control

("major positioning control") set in the positioning data

with the designated conditions, so first carry out

preparations so that "major positioning control" can be

executed.

STEP 2

The "block start data" from 1 to 50 points can be set.

Set the "block start data" corresponding to each

control

(Note-1)

.

( Da. 11 to Da. 14 ) × required data amount

Refer to Section 10.3

STEP 3

STEP 4

Refer to Section 10.6

Refer to Section 10.4

Create a sequence program in which block No. is set in

the

" Cd. 3 Positioning start No."

(Note-1)

(Control data setting)

Starting the control

Monitoring the control

Control termination

STEP 5

Refer to Chapter 6

STEP 6

STEP 7

Create a sequence program in which the "positioning

start signal" is turned ON by a positioning start command.

Write the sequence programs created in STEP4

to the PLC CPU.

Turn ON the "positioning start command" of

the axis to be started.

Stopping the control

STEP 8

Stop when control is completed

Monitor the high-level positioning control.

Refer to Section 6.5.3

Refer to Section 6.5.6

Create a sequence program in which the "block start

data point No. to be started" (1 to 50) is set in the

" Cd. 4 Positioning starting point No.

"

Set the "condition data" for designation with the

"block start data". Up to 10 condition data items

can be set.

The Simple Motion module recognizes that the control

is high-level positioning control using "block start data"

by the "7000" designation.

Use GX Works2 to create a sequence program

to execute the "high-level positioning control".

Write the sequence program created in STEP 4 to the

PLC CPU using GX Works2.

Same procedure as for the "major positioning control"

start.

Monitor using GX Works2

.

Same procedure as for the "major positioning control" stop.

Set the "condition data"

(Note-1)

.

( Da. 15 to Da. 19 and Da.23 to Da.26 ) ×

required data amount

REMARK

(Note-1): Five sets of "block start data (50 points)" and "condition data (10 items)"

corresponding to "block No. 7000 to 7004" are set with GX Works2 or

sequence program.

"7000 to 7004" can be set in "[Cd.3] Positioning start No." on STEP4 when

the above is set.