10 - 27

Chapter 10 High-Level Positioning Control

10.6.2 Example of a start program for high-level positioning control

The following shows an example of a start program for high-level positioning control in

which the 1st point "block start data" of axis 1 is started. (The block No. is regarded as

"7000".)

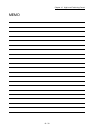

Control data that require setting

The following control data must be set to execute high-level positioning control.

The setting is carried out using a sequence program.

Setting item

Setting

value

Setting details

Buffer memory address

QD77MS2

QD77MS4

QD77MS16

[Cd.3] Positioning start No. 7000

Set "7000" to indicate control using "block

start data".

1500+100n 4300+100n

[Cd.4]

Positioning starting

point No.

1

Set the point No. of the "block start data" to

be started.

1501+100n 4301+100n

n: Axis No.-1

(Note): Refer to Section 5.7 "List of control data" for details on the setting details.

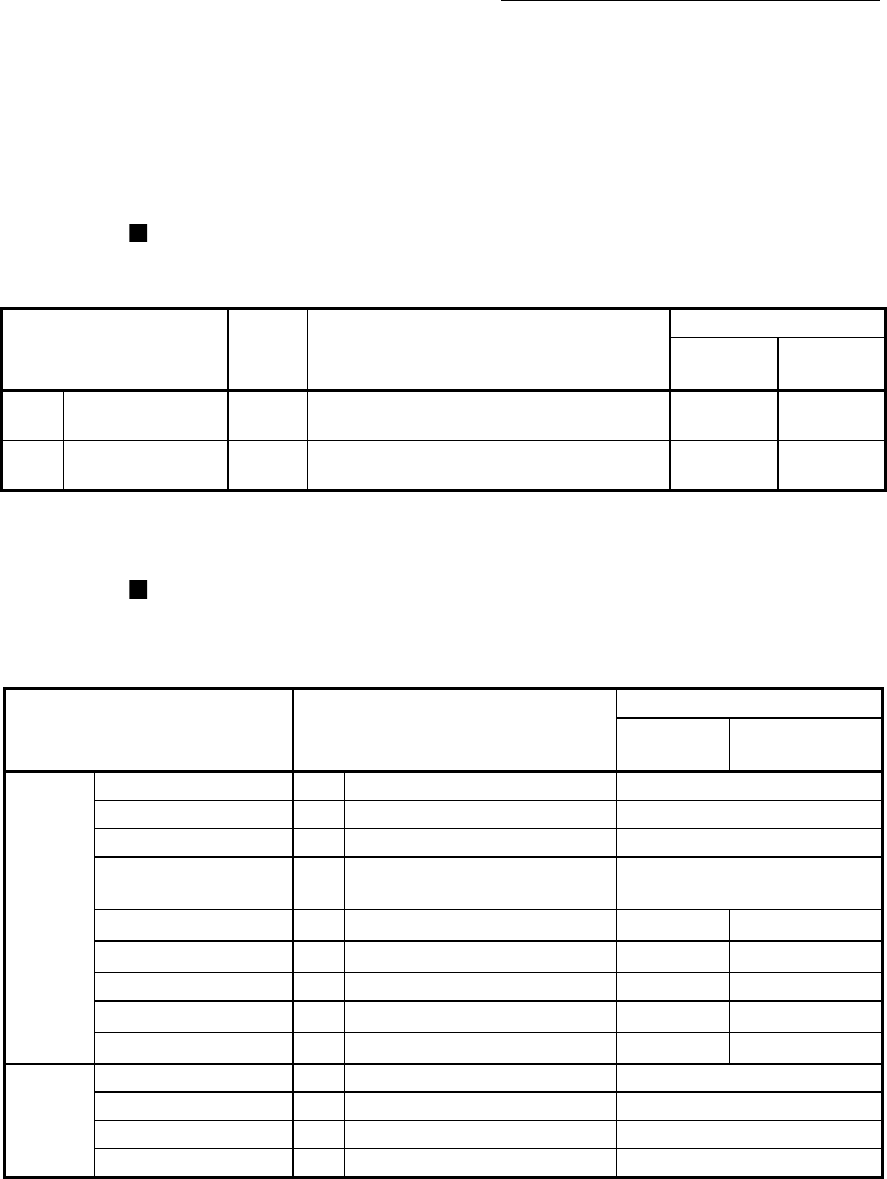

Start conditions

The following conditions must be fulfilled when starting the control. The required

conditions must also be integrated into the sequence program, and configured so

the control does not start unless the conditions are fulfilled.

Signal name Signal state

Device

QD77MS2

QD77MS4

QD77MS16

Interface

signal

PLC READY signal ON PLC CPU preparation completed Y0

READY signal ON QD77MS preparation completed X0

All axis servo ON ON All axis servo ON Y1

Synchronization flag ON

QD77MS buffer memory

The access is possible.

X1

Axis stop signal OFF Axis stop signal is OFF Y4 to Y7 [Cd.180] Axis stop

Start complete signal OFF Start complete signal is OFF X10 to X13 [Md.31] Status: b14

BUSY signal OFF BUSY signal is OFF XC to XF X10 to X1F

Error detection signal OFF There is no error X8 to XB [Md.31] Status: b13

M code ON signal OFF M code ON signal is OFF X4 to X7 [Md.31] Status: b12

External

signal

Forced stop input signal ON There is no forced stop input –

Stop signal OFF Stop signal is OFF –

Upper limit (FLS) ON Within limit range –

Lower limit (RLS) ON Within limit range –