8 - 13

Chapter 8 OPR Control

8.2.6 OPR method (4): Data set method

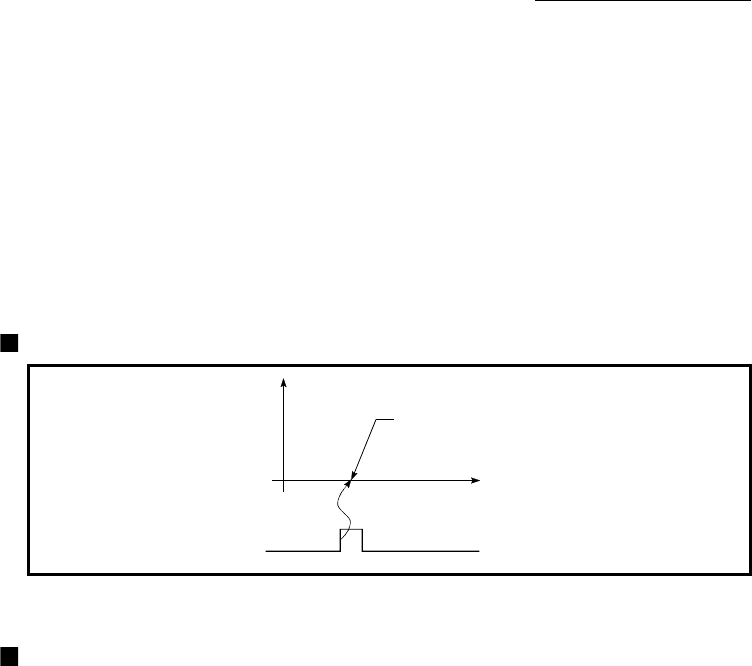

The following shows an operation outline of the OPR method "data set method".

The "Data set method" method is effective when a "Near-point dog" is not used.

It can be used with absolute position system.

With the data set method OPR, the position where the machine OPR has been carried

out, is registered into the Simple Motion module as the OP, and the current feed value

and feed machine value is overwritten to an OP address.

Use the JOG or manual pulse generator operation to move the OP.

Operation chart

OPR start

The address upon execution

of the OPR is registered as

an OP address.

t

Fig. 8.9 Data set method OPR

Precautions during operation

(1) The zero point must have been passed before the OPR is carried out after the

power supply is turned ON. If the OPR is carried out without passing the zero

point even once, the error "OPR zero point not passed" (error code: 210) will

occur. When the error "OPR zero point not passed" (error code: 210) occurs,

perform the JOG or similar operation so that the servomotor makes more than

one revolution after an error reset, before carrying out the machine OPR again.

However, if selecting "1: Not need to pass servo motor Z-phase after power

on" with "Function selection C-4 (PC17)", it is possible to carry out the home

position return (OPR) without passing the zero point.

(2) The OPR data used for the data set method is the "OPR direction" and "OP

address".

The OPR data other than that for the OPR direction and OP address is not

used for the data set method OPR method, but if a value is set the outside the

setting range, an error will occur when the PLC READY signal [Y0] is turned

ON so that the READY signal [X0] is not turned OFF.

With the OPR data other than that for the OPR direction and OP address, set

an arbitrary value (default value can be allowed) within each data setting

range so that an error will not occur upon receiving the PLC READY signal

[Y0] ON.