12

4.1 Flow of Site Adjustment

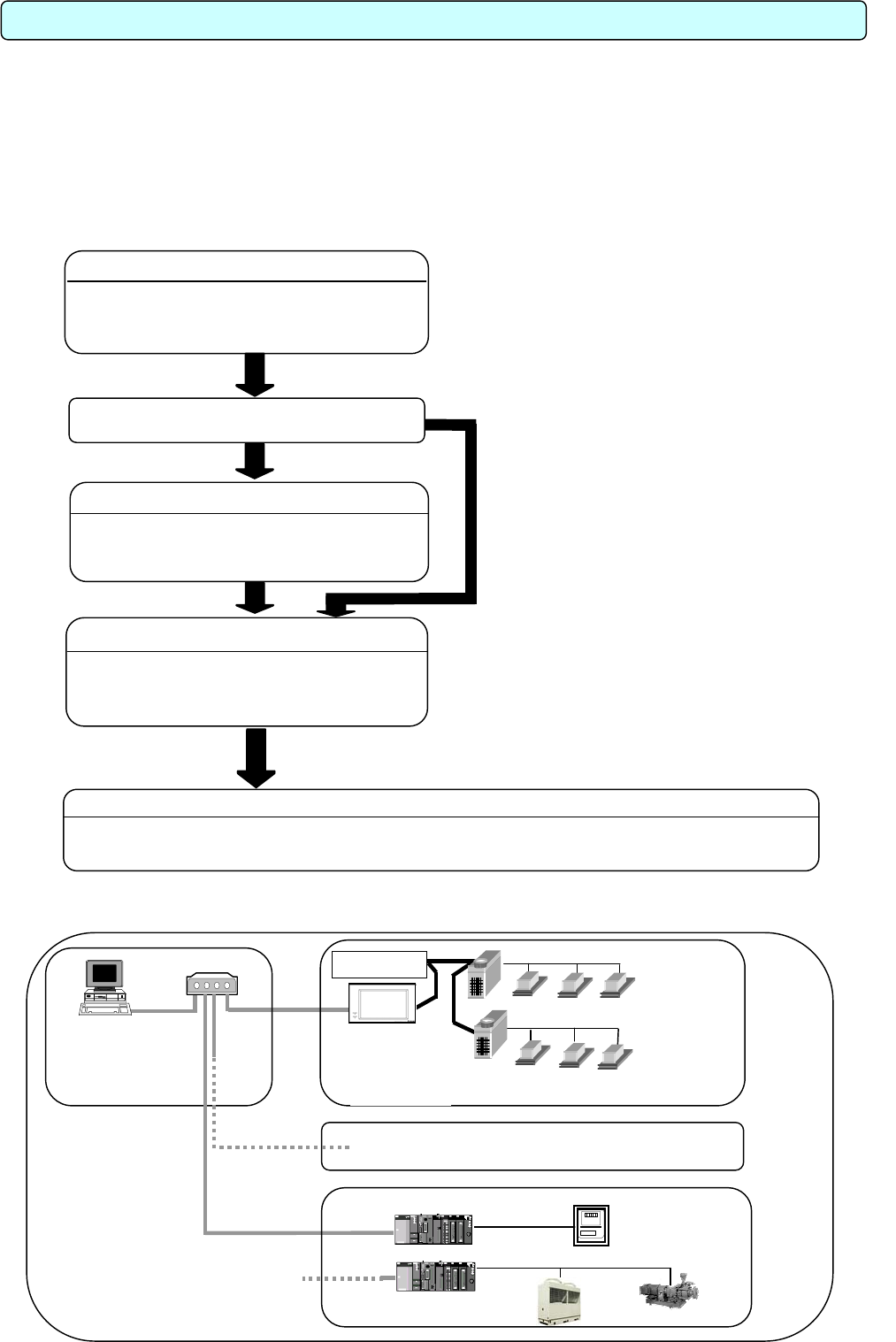

When the task of site adjustment is subdivided into smaller tasks as shown in the figure below, the

tasks can be broadly grouped into four steps. The benefit of following these for steps when carrying

out the tasks of site adjustment is that if troubles do arise, it will be clear which step caused the

problem. This makes it easier to solve problems and this results in a more efficient execution of site

adjustment tasks.

(Step 2 can be skipped when not using the PLC.)

Carry out site adjustment, by following the step by step instructions shown below.

<System example>

4. Flow of Site Adjustment

Step 1 AG-150A/G-50A test run

Check that the air conditioners and controllers

are correctly configured and that the air con-

ditioner works.

* Refer to Chapter 4 in this booklet for details.

* For the test operation method of the air conditioner,

DIDO controller, AI controller, PI controller

and central controller AG-150A/G-50A, refer to the

relevant installation manuals.

* Check that only the air conditioner test

operation has been completed before starting

Ste

p

1.

Step 3 PC connections and settings

Connect and set up the software and hard-

ware on the PC with TG-2000A installed.

Check that it is ready for operation.

Step 4 TG-2000A system test run

Check that the TG-2000A man-machine system can correctly operate air conditioner units of all

the managed systems by issuing TG-2000A commands.

Step 2 PLC connections and installation

Connect the PLC and device hardware, and

install the PLC software into the PLC. *1

*1. Refer to the instruction manual for the PLC,

electric amount count software or PLC fo

r

general equipment software.

LAN

Power supply unit

Step 1

Step 4

Step 3

Integrated centralized

control software

TG-2000A

HUB

A

G-150

A

or G-50

A

Step 2

Step 1

PLC

Meters

(electricity, gas,

water, calorific

value

)

Pulse

Status monitor

Chiller Pump

Use PLC?

* If PLC is not used, step 2 can be skipped.

YES

NO