14. USING A LINEAR SERVO MOTOR

14 - 1

14. USING A LINEAR SERVO MOTOR

WARNING

When using the linear servo motor, read "Linear Servo Motor Instruction Manual"

and "Linear Encoder Instruction Manual".

14.1 Functions and configuration

14.1.1 Summary

The fields of semiconductor/LCD manufacturing systems, mounters, and others have strong demands for

high accuracy, high speed, and efficiency. Therefore, the number of systems using a linear servo motor for a

drive axis has been increasing. Since the linear servo system can obtain the characteristics of the high

speed and the high acceleration/deceleration greater than the ball screw drive system. The linear servo

system also does not have a ball screw wear which is a weak point in the ball screw drive system. This will

extend the life of the equipment. In addition, since a response error due to backlash and friction does not

occur, you can establish a high-accuracy system.

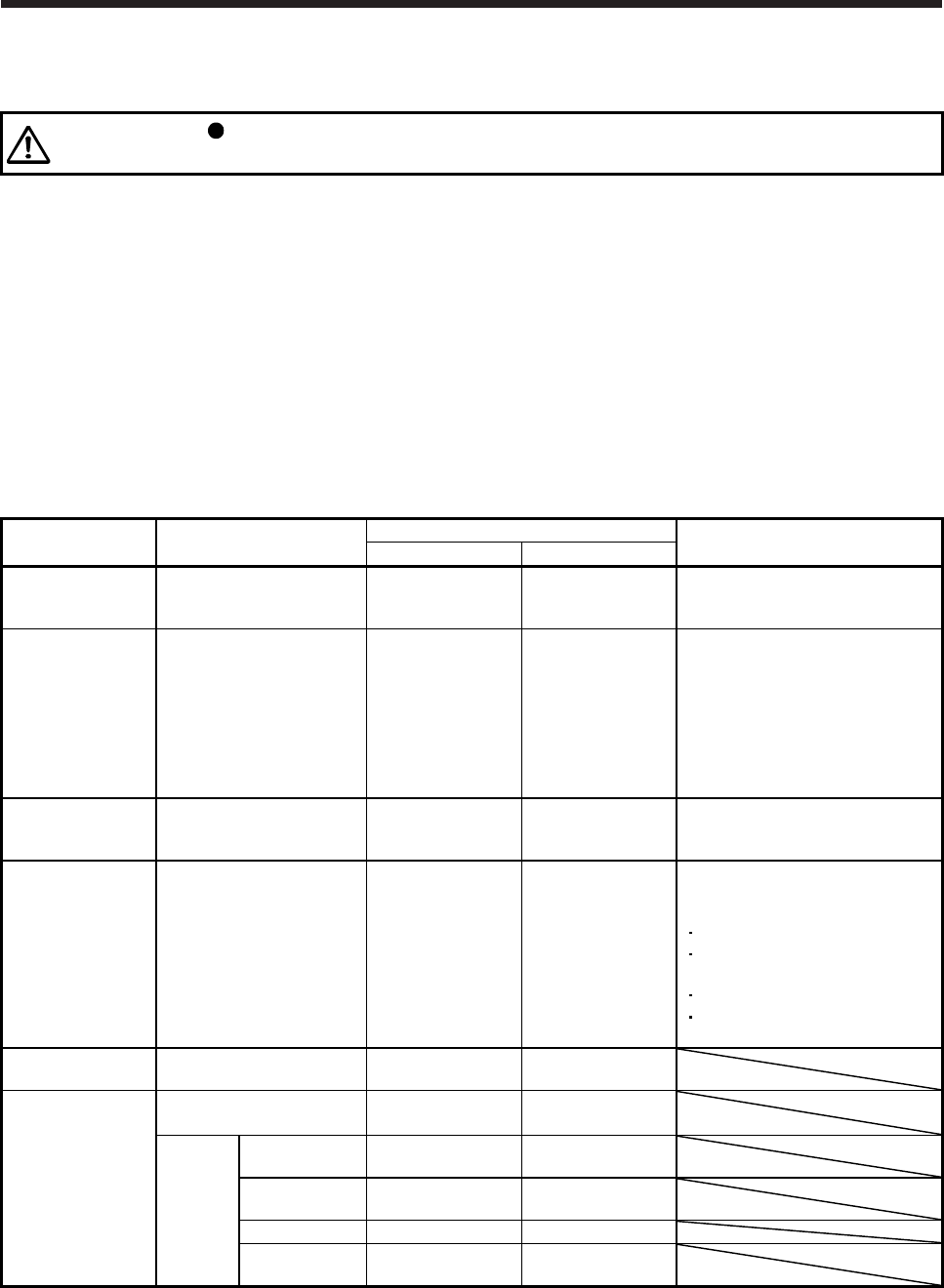

The following shows the differences between the linear servo motor and the rotary servo motor.

Category Item

Differences

Remarks

Linear servo motor Rotary servo motor

External I/O signal FLS (Upper stroke limit),

RLS (Lower stroke limit)

Required (for

magnetic pole

detection)

Not required Automatically turns on in the

parameter setting.

Motor pole

adjustment

Magnetic pole detection Required Not required

(default setting)

Automatically executed at the first

servo-on after the power is turned

on.

For the absolute position linear

encoder, [Pr. PL01] can disable the

magnetic pole detection. The timing

of the magnetic pole detection can

be changed with [Pr. PL01]. (Refer

to (2) (b) of section 14.3.3.)

Home position

return

Reference home position 1048576 pulses unit

(initial value)

One servo motor

revolution unit

Home position return pitch can be

changed with parameter setting.

(Refer to section 14.3.3)

Absolute position

detection system

Absolute position encoder

battery

Not required Required The following alarms and warnings

are not provided for the linear servo

motor.

[AL. 25 Absolute position erased]

[AL. 92 Battery cable

disconnection warning]

[AL. 9F Battery warning]

[AL. E3 Absolute position counter

warning]

Auto tuning Load to motor inertia ratio

(J)

Load to motor mass

ratio

Load to motor

inertia ratio

MR Configurator2

(SW1DNC-MRC2-E)

Motor speed

(Data display and setting)

mm/s unit r/min unit

(Software version

1.19V or later)

Test

operation

function

Positioning

operation

Supported Supported

Motor-less

operation

None Supported

JOG operation None Supported

Program

operation

Supported Supported