Emerson Process Management GmbH & Co. OHG3-20

X-STREAM X2

Instruction Manual

HASX2E-IM-HS

02/2012

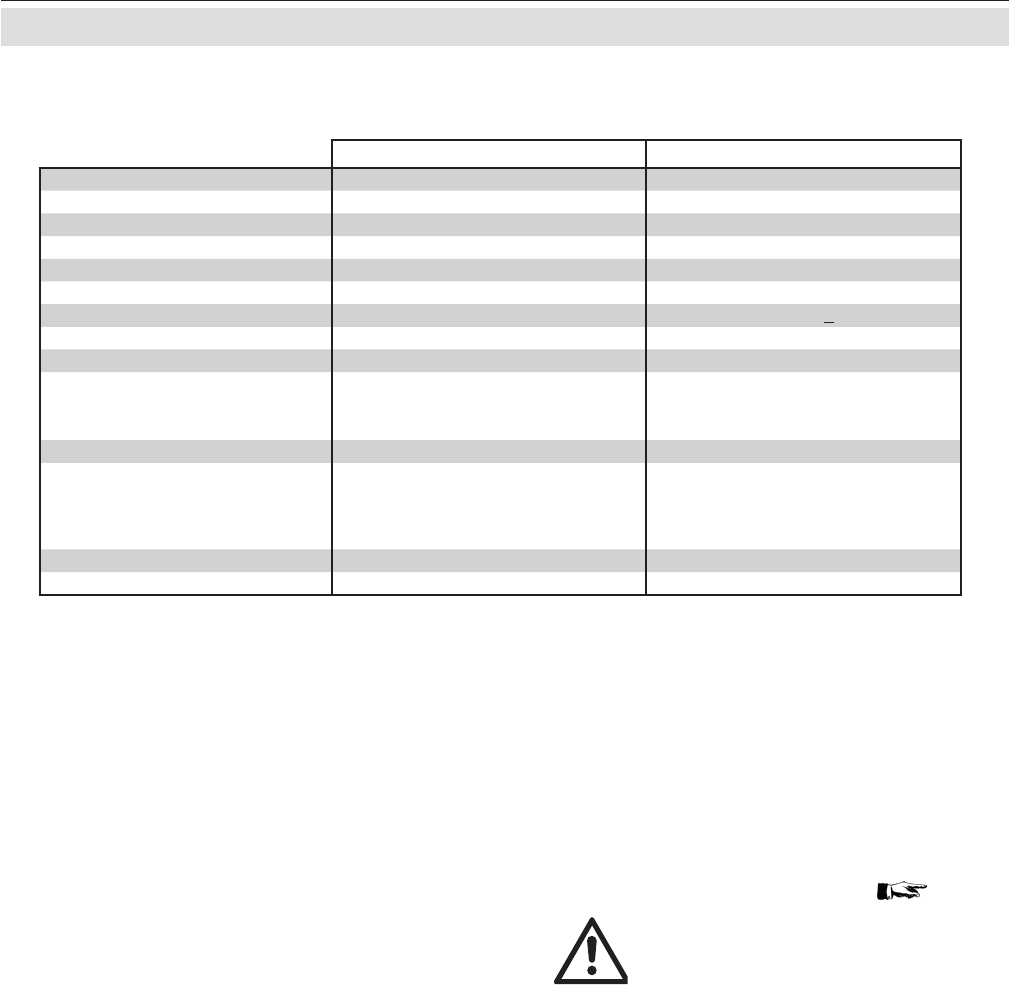

3.5 Measurement Specications

Tab. 3-9: IR, UV, VIS, TCD - Measurement Performance Specications

The specications given in these tables al-

ways apply to the physical measuring ranges,

as listed e.g. in the INFO-RANGES.. menu

(parameters „MinRange“ and „MaxRange“).

Scaling or zooming ( 5.7.4,

page 5-20) cannot improve ana-) cannot improve ana-

log output specifications to

values better than specied by

the physical measuring ranges

Important Notes Concerning Measurement Specication Data

All performance data is veried during the manufacturing process for each unit by the following

tests:

• Linearization and sensitivity test

• Long term drift stability test

• Climate chamber test

• Cross interference test (if applicable)

Measurement Performance Specications

NDIR/UV/VIS Thermal Conductivity (TCD)

Detection limit (4 σ)

1 4

≤ 1 % ≤ 1 %

Linearity

1 4

≤ 1 % ≤

1 %

Zero-point drift

1 4

≤ 2 % per week ≤ 2 % per week

Span (sensitivity) drift

1 4

≤ 0.5 % per week ≤ 1 % per week

Repeatability

1 4

≤ 1 % ≤

1 %

Response time (t

90

)

3

4 s ≤ t

90

≤ 7 s

5

15 s ≤ t

90

≤ 30 s

6

Permissible gas ow 0.2–1.5 l/min. 0.2–1.5 l/min. (

+

0.1 l/min)

Inuence of gas ow

1 4

≤ 0.5 % ≤ 1 %

11

Maximum gas pressure

8 14

≤ 1500 hPa abs. (≤ 7 psig) ≤ 1500 hPa abs. (≤ 7 psig)

Inuence of pressure

2

– At constant temperature ≤ 0.10 % per hPa ≤ 0.10 % per hPa

– With pressure compensation

7

≤ 0.01 % per hPa ≤ 0.01 % per hPa

Permissible ambient temperature

9

0 (-20) to +50 °C (32 (-4) to 122 °F) 0 (-20) to +50 °C (32 (-4) to 122 °F)

Inuence of temperature

1 13

(at constant pressure)

– On zero point ≤ 1 % per 10 K ≤ 1 % per 10 K

– On span (sensitivity) ≤ 5 % (0 to +50 °C / 32 to 122 °F) ≤ 1 % per 10 K

Thermostat control

6 12

none / 60 °C (140 °F)

5

none / 60 °C (140 °F)

10

Warm-up time

6

15 to 50 minutes

5

approx. 50 minutes

Note! 1 psi = 68.95 hPa

1

Related to full scale

2

Related to measuring value

3

From gas analyzer inlet at gas ow of 1.0 l/min

(electronic damping = 0 s)

4

Constant pressure and temperature

5

Dependent on integrated photometer bench

6

Depending on measuring range

7

Pressure sensor is required

8

Limited to atmospheric if internal sample pump

9

Temperatures below 0 °C (-4 °F) with thermo-

stat control only

10

Thermost. controlled sensor: 75 °C (167 °F)

11

Flow variation within

±

0.1 l/min

12

Optional thermostatically controlled box with

temperature 60 °C (140 °F), not X2GK

13

Temperature variation: ≤

10 K per hour

14

Special conditions apply to model X2FD