Emerson Process Management GmbH & Co. OHG 7-3

X-STREAM X2

Instruction Manual

HASX2E-IM-HS

02/2012

7

Maintenance & Procedures

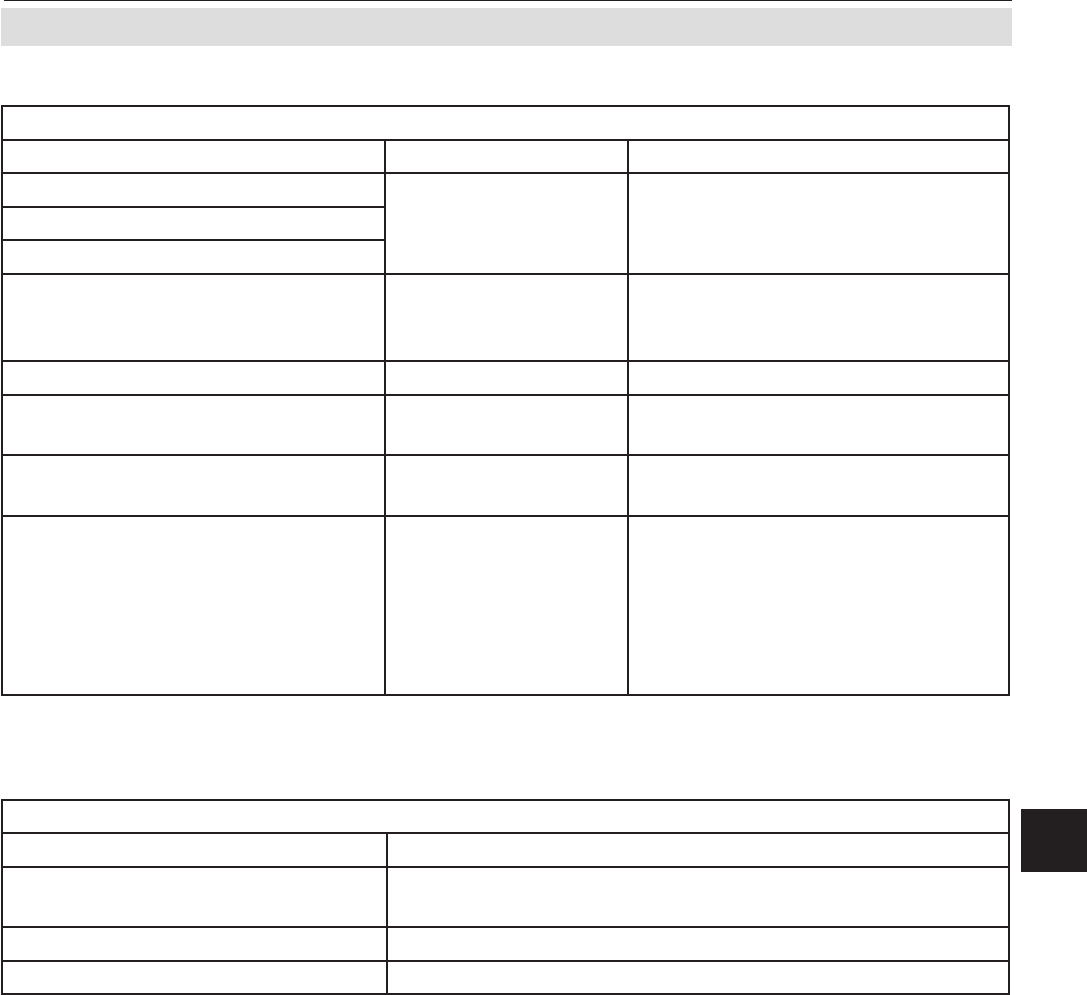

7.2 General Maintenance Information

Tests

Component Interval

Tubing, exible

Leak Test Once a yearPressure sensor, pressure switch

Valve block

Pump diaphragm Leak Test

After 5,000 hrs of operation

(=208 days, if continuously opera-

ting)

Capillars Pressure drop Once a year

Flame arrestors Pressure drop

See instructions in separate ma-

nual

Infallible containments Several

See instructions in separate ma-

nual

RAW measuring values

Verify counts for zero

gases

(decreasing counts

may indicate conta-

mination of optical

components)

Monthly, then quarterly

Acceptable values:

photometer quotient: 1.0 ± 0.1

NO, N

2

O quotient: 1.0 ± 0.2

pO

2

, eO

2

, TC: 0 ± 100,000 counts

(for zero gas N

2

)

Replace Components Regularly

Component Interval

Electrochemical oxygen cell

Depending on output signal (see details later in this sec-

tion)

Filter, internal Once a year, at least when contaminated

Filter, external Several times a year, depending on process conditions