Emerson Process Management GmbH & Co. OHG6-42

X-STREAM X2

Instruction Manual

HASX2E-IM-HS

02/2012

6.2 Menu System - IntSHS Menu

Note!

Each virtual valve V1 to V8 is normally only

assigned to one gas inlet, “Gas1” to “Gas8”

.

Double assignments are possible, but only

meaningful if the unit is congured accordin-

gly.

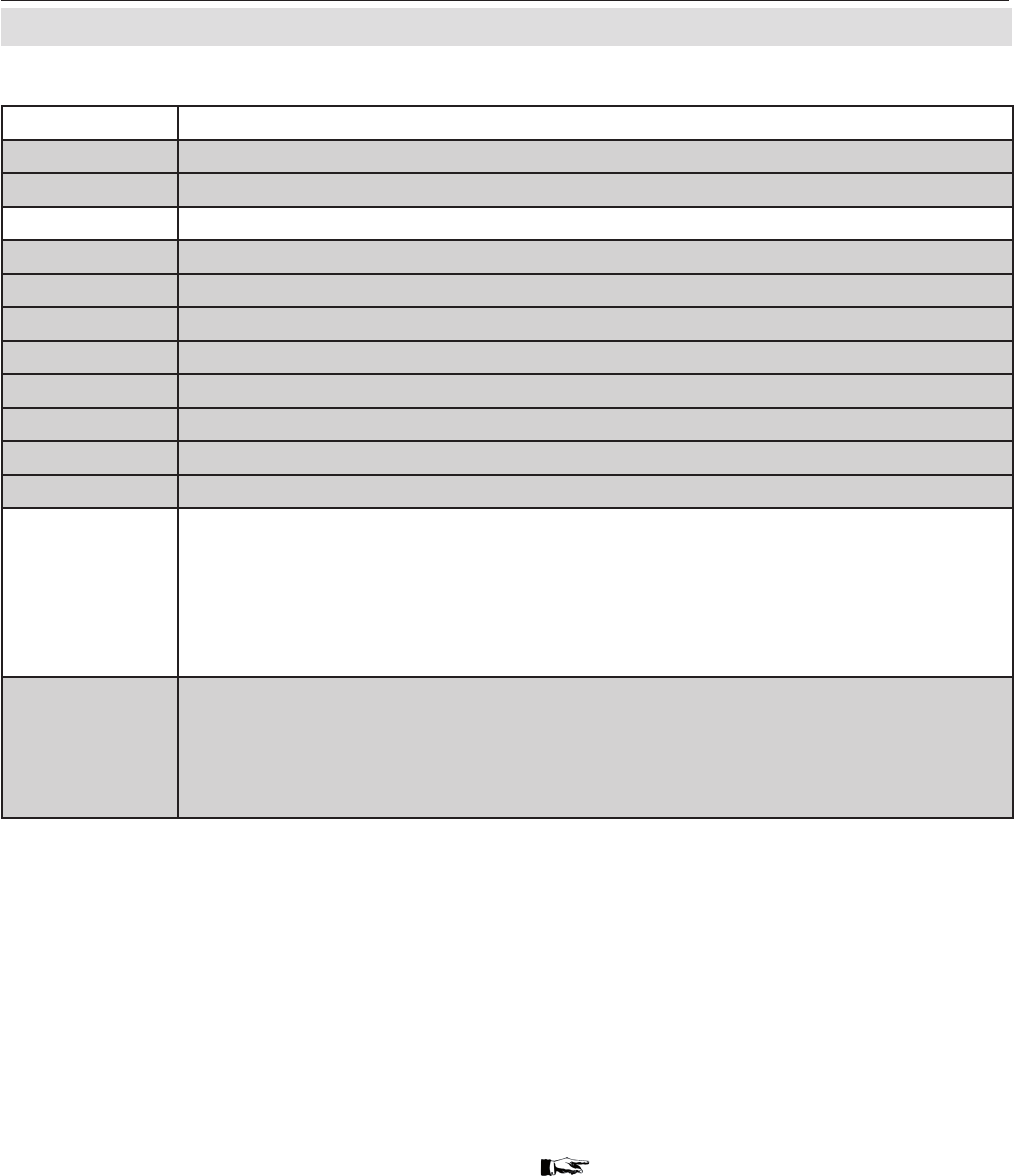

Label Description

Off Switches the assigned component (valve or pump) off.

On Switches the assigned component (valve or pump) on.

Test Switches the assigned component (valve or pump) on and off every second.

V1 Valve at selected gas inlet is assigned the value “V1”

V2 Valve at selected gas inlet is assigned the value “V2”

V3 Valve at selected gas inlet is assigned the value “V3”

V4 Valve at selected gas inlet is assigned the value “V4”

V5 Valve at selected gas inlet is assigned the value “V5”

V6 Valve at selected gas inlet is assigned the value “V6”

V7 Valve at selected gas inlet is assigned the value “V7”

V8 Valve at selected gas inlet is assigned the value “V8”

Sample

The gas inlet is a sample gas inlet. The valve assigned to it is controlled via

the Sample software option.

Note!

There is only one option Sample . This means that in order to control two sample

gas valves during autocalibration, the value Sample must be assigned to two

inlets. During calibration, both valves are then controlled synchronously.

Pump

The pump is controlled by the Pump software option.

Note!

There is only one option

Pump. This means that in order to control two pumps

during autocalibration, the lines “Pump1” and “Pump2” must be assigned the value

Pump. During calibration, both pumps are then controlled synchronously.

Chapter 7 includes detailed descriptions

of the conguration and execution of calibra-

tions with valves.

Tab. 6-4: Parameter IntSHS options