3 - 6

3. SIGNALS AND WIRING

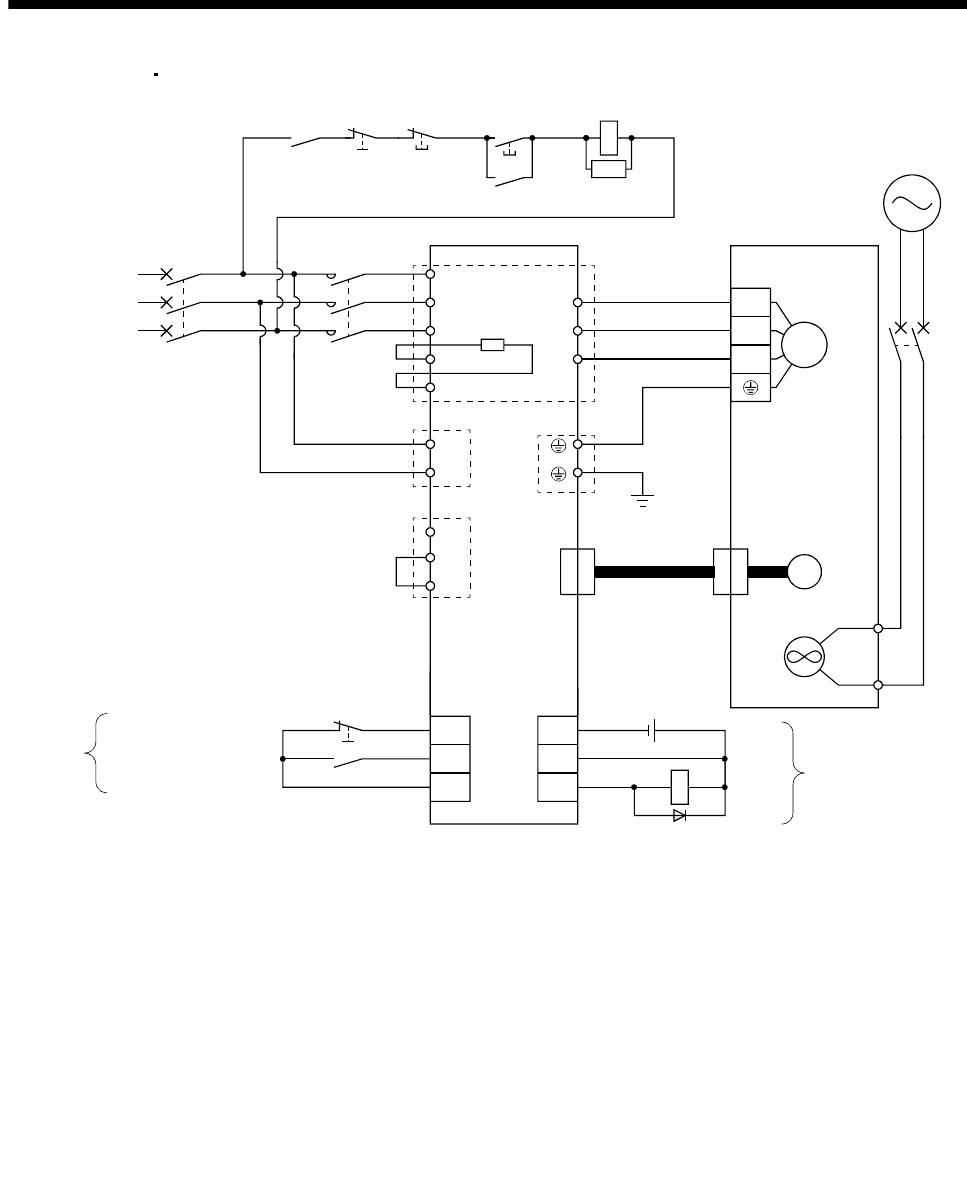

(5) MR-J3-500A MR-J3-700A

TE1

TE2

TE3

Built-in

regenerative

resistor

Cooling fan

BU

BV

NFB

(Note 6)

Power supply

of cooling fan

P

N

(Note 4)

SON

EMG

L

1

L

2

L3

3-phase

200 to

230VAC

ALM

P

1

P2

DICOM

DOCOM

L

11

L

21

C

U

V

W

(Note 1)

(Note 2)

PE

U

V

W

M

Motor

Encoder

CN2

(Note 3)

Encoder cable

(Note 5)

DOCOM

CN1 CN1

24VDC

Trouble

(Note 4)

MCNFB

RA

Servo motorServo amplifier

Emergency stop (Note 7)

Servo-on

(Note 8)

Trouble

RA

Emergency stop

OFF

MC

ON

MC

SK

(Note 7)

Note 1. Always connect P1 and P2. (Factory-wired.) When using the power factor improving DC reactor, refer to section 12.13. Use only

one of power factor improving DC reactor or power factor improving AC reactor.

2. When using the regenerative option, refer to section 12.2.

3. For encoder cable, use of the option cable is recommended. Refer to section 12.1 for selection of the cable.

4. For the sink I/O interface. For the source I/O interface, refer to section 3.8.3.

5. Refer to section 3.10.

6. A cooling fan is attached to the HA-LP601 and the HA-LP701M servo motors. For power supply specification of the cooling fan,

refer to section 3.10.2 (3) (b).

7. Configure the circuit to shut down the main circuit power supply simultaneously with the turn off of emergency stop (EMG) using

the external sequence.

8. Be sure to use a magnetic contactor with an operation delay time of 80ms or less. The operation delay time is the time interval

between current being applied to the coil until closure of contacts.