4 - 3

4. STARTUP

2) When regenerative option is used over 5kW for 200V class and 3.5kW for 400V class

The lead of built-in regenerative resistor connected to P terminal and C terminal of TE1 terminal

block should not be connected.

The generative brake option should be connected to P terminal and C terminal.

A twisted cable should be used when wiring is over 5m and under 10m. (Refer to section 12.2)

3) When brake unit and power regenerative converter are used over 5kW

The lead of built-in regenerative resistor connected to P terminal and C terminal of TE1 terminal

block should not be connected.

Brake unit, power regenerative converter or power regenerative common converter should be

connected to P terminal and N terminal. (Refer to section 12.3 to 12.5)

4) The power factor improving DC reactor should be connected P

1 and P2 (For 11k to 22kW, P

1

and P).

(Refer to section 12.13.)

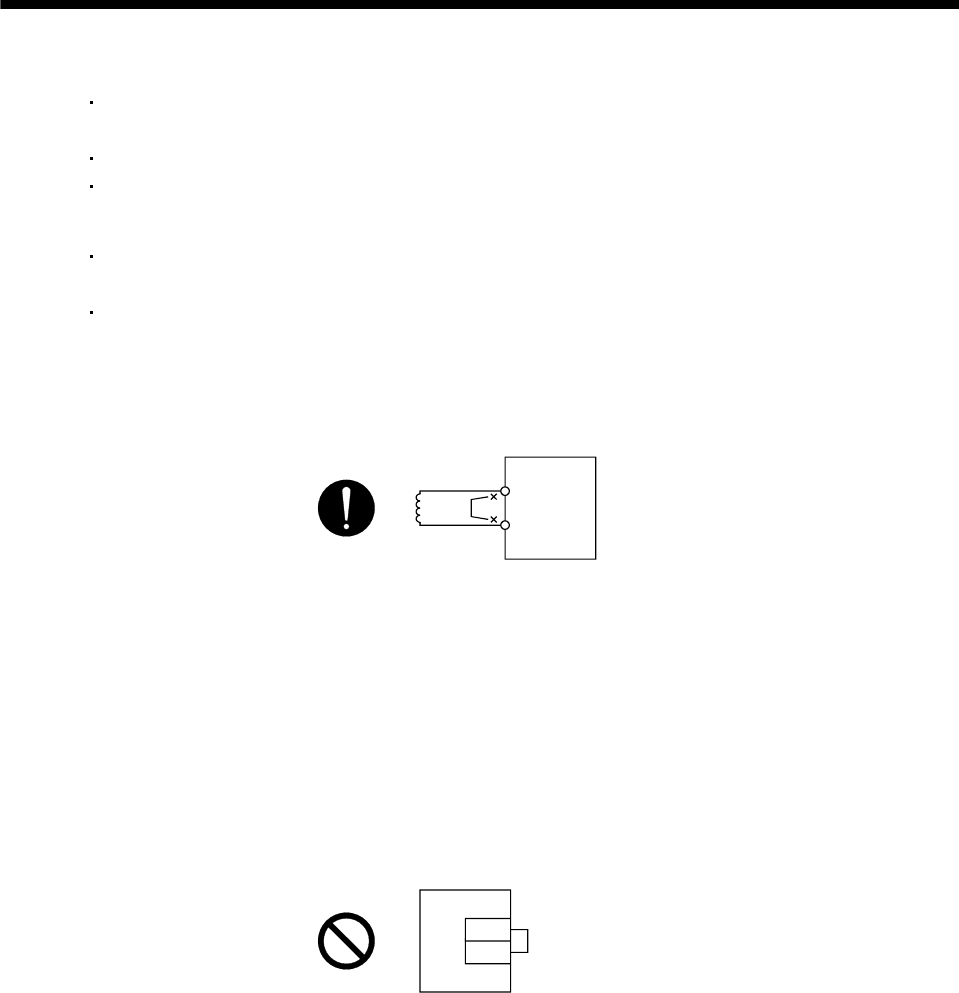

(Note)

Power factor

improving DC

reactor

Servo amplifier

P1

P2

Note. Always disconnect P1 and P2 (For 11k to 22kW, P

1

and P).

(2) I/O signal wiring

(a) The I/O signals should be connected correctly.

Use DO forced output to forcibly turn on/off the pins of the CN1 connector. This function can be used to

perform a wiring check. (Refer to section 6.8.) In this case, switch on the control circuit power supply

only.

(b) 24VDC or higher voltage is not applied to the pins of connectors CN1.

(c) SD and DOCOM of connector CN1 is not shorted.

DOCOM

SD

CN1

Servo amplifier

4.1.3 Surrounding environment

(1) Cable routing

(a) The wiring cables are free from excessive force.

(b) The encoder cable should not be used in excess of its flex life. (Refer to section 11.4.)

(c) The connector part of the servo motor should not be strained.

(2) Environment

Signal cables and power cables are not shorted by wire offcuts, metallic dust or the like.