4 - 18

4. STARTUP

4.4.5 Actual operation

Start actual operation after confirmation of normal operation by test operation and completion of the

corresponding parameter settings.

4.4.6 Trouble at start-up

CAUTION

Excessive adjustment or change of parameter setting must not be made as it will

make operation instable.

POINT

Using the MR Configurator, you can refer to unrotated servo motor reasons, etc.

The following faults may occur at start-up. If any of such faults occurs, take the corresponding action.

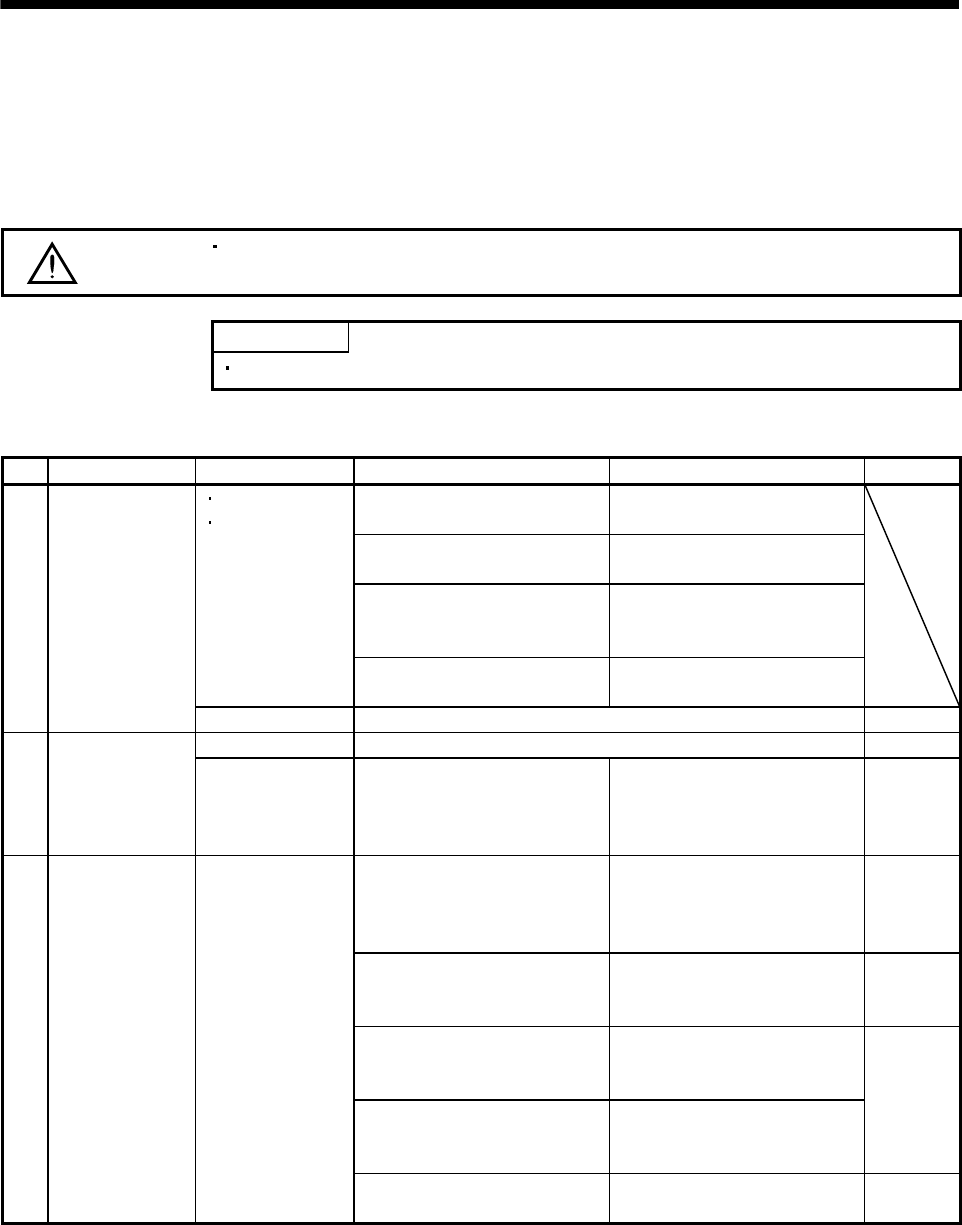

No. Start-up sequence Fault Investigation Possible cause Reference

1 Power on LED is not lit.

LED flickers.

Not improved if connectors CN1,

CN2 and CN3 are disconnected.

1. Power supply voltage fault

2. Servo amplifier is faulty.

Improved when connectors CN1

is disconnected.

Power supply of CN1 cabling is

shorted.

Improved when connector CN2 is

disconnected.

1. Power supply of encoder

cabling is shorted.

2. Encoder is faulty.

Improved when connector CN3 is

disconnected.

Power supply of CN3 cabling is

shorted.

Alarm occurs. Refer to chapter 9 and remove cause. Chapter 9

2 Switch on servo-

on (SON).

Alarm occurs. Refer to chapter 9 and remove cause. Chapter 9

Servo motor shaft is

free.

Call the external I/O signal display

(section 6.7) and check the

ON/OFF status of the input signal.

1. Servo-on (SON) is not input.

(Wiring mistake)

2. 24VDC power is not supplied to

DICOM.

Section 6.7

3 Switch on forward

rotation start

(RS1) or reverse

rotation start

(RS2).

Servo motor does

not rotate.

Call the status display or MR

Configurator (section 6.3) and

check the analog torque

command (TC).

Analog torque command is 0V. Section 6.3

Call the external I/O signal display

(section 6.7) and check the

ON/OFF status of the input signal.

RS1 or RS2 is off. Section 6.7

Check the internal speed limits 1

to 7

(parameters No.PC05 to PC11).

Set value is 0. Section 5.3

Check the analog torque

command maximum output

(parameter No.26) value.

Torque command level is too low

as compared to the load torque.

Check the internal torque limit 1

(parameter No.PC13).

Set value is 0. Section

5.1.11