5 - 35

5 MOTION DEDICATED PLC INSTRUCTION

[Controls]

(1) This instruction is dedicated instruction toward the Motion CPU in the Multiple

CPU system. Errors occurs when it was executed toward the CPU except the

Motion CPU.

(2) The torque limit value of the axis specified with (S1) is changed to the value of

(S2) regardless of the state of during operating or stopping at the real mode.

(3) S(P).SFCS/S(P).SVST/S(P).CHGA/S(P).CHGV/S(P).CHGT/S(P).DDRD/

S(P).DDWR cannot be executed simultaneously toward the CPU executing

S(P).CHGT instruction.

When the Motion dedicated PLC instruction is started continuously, It is necessary

to take an inter-lock by the to self CPU high speed interrupt accept flag from

CPUn.

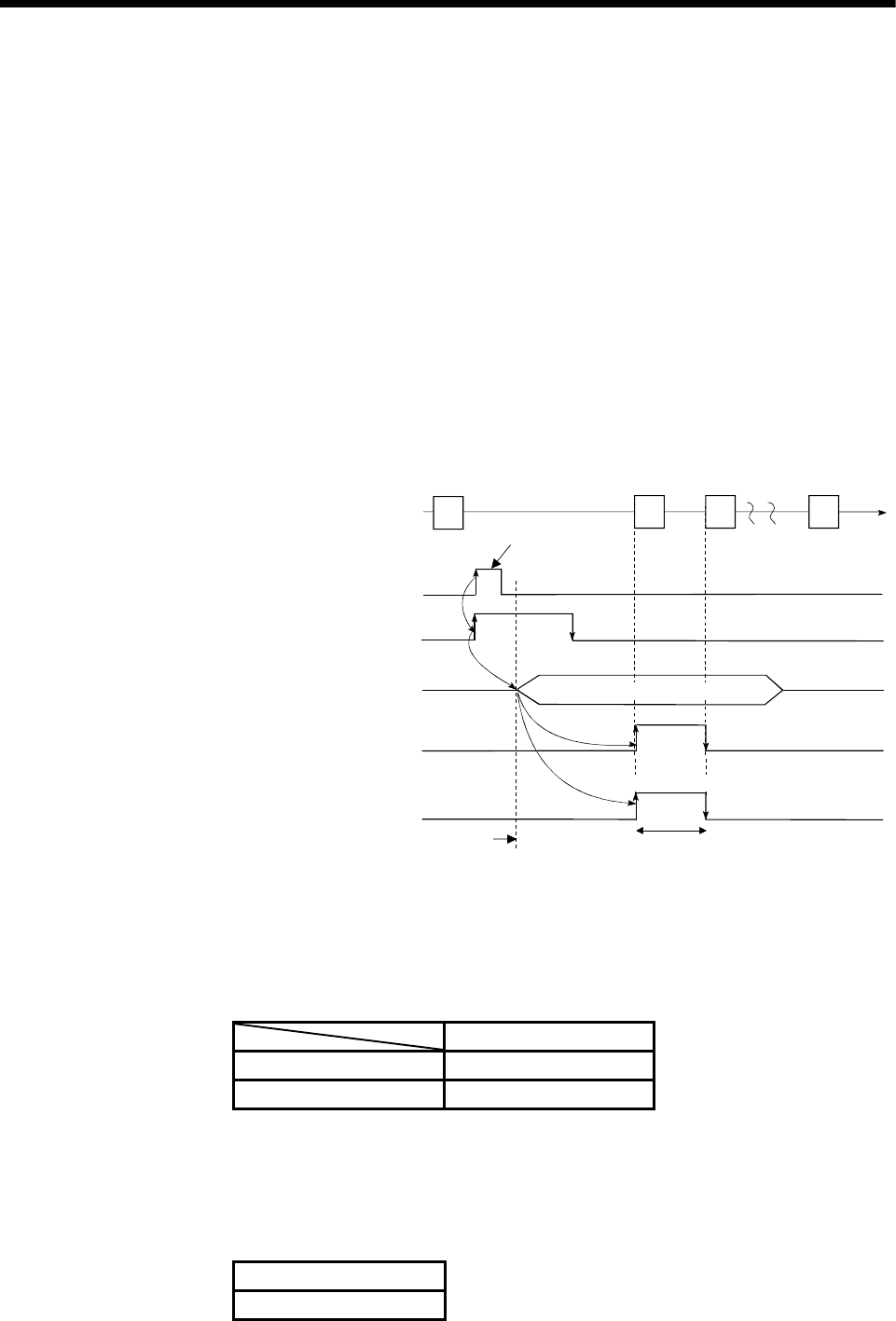

[Operation]

State display device (D1+1)

at the instruction start

accept completion

t

ON

ON

S(P).CHGT instruction

OFF

ON

OFF

OFF

OFF

1 scan

PLC program

Instruction accept

completion at the

Motion CPU side

END

END

END

END

Torque limit value change

S(P).CHGT execution

Instruction start accept

complete device (D1+0)

To self CPU high speed interrupt

accept flag from CPUn

ON : Abnormal completion only

Torque limit value change processing

[Setting range]

(1) Setting of the axis to execute the torque limit value change.

The axis to execute the torque limit change set as (S1) sets J + axis No. in a

character sequence " ".

(S1) usable range

Q173CPU(N) 1 to 32

Q172CPU(N) 1 to 8

The number of axes which can set are only 1 axis.

The axis No. set in the system setting (Refer to Section 1.5) is used as the axis

No. to start.

(2) Setting of the torque limit value to change.

(S2) usable range

1 to 500