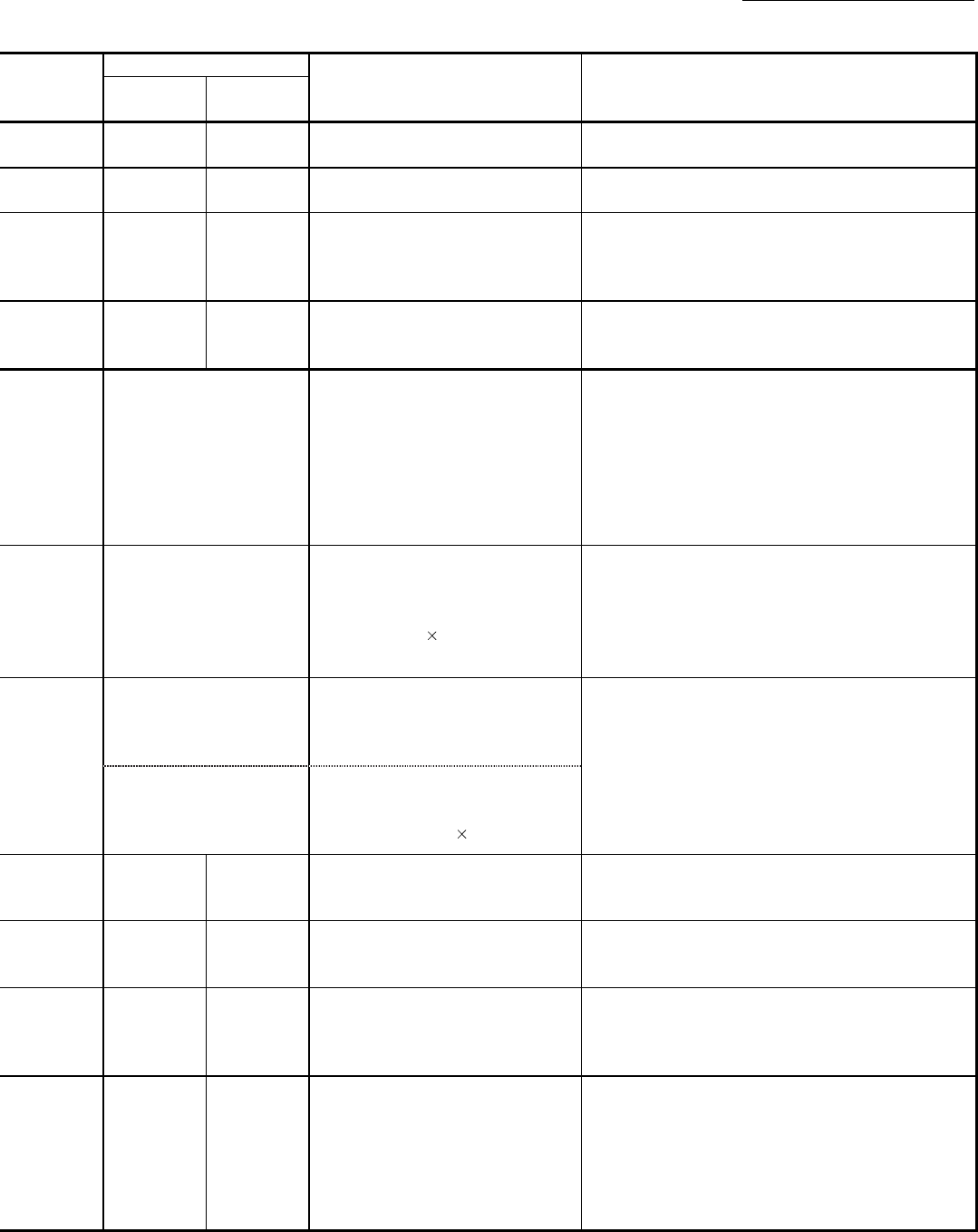

16 - 19

Chapter 16 Troubleshooting

Related buffer memory address

Set range

(Setting with sequence program)

Remedy

QD77MS2

QD77MS4

QD77MS16

— — —

Turn ON the PLC READY signal [Y0] with the BUSY signals

of all axes OFF.

— — —

Do not request the start when the axis operation state is other

than "standby", "stop", and "step standby".

30100+200n 28400+100n

<Servo series>

0, 1, 3, 4, 6, 7, 32, 48, 64, 96

Match the set series of the servo parameter "[Pr.100] Servo

series" to the series of connected servo amplifier.

147 105 —

Review the content of the positioning or "[Pr.96] Operation

cycle setting" longer than the current setting.

78+150n

<OPR retry>

0, 1

• Validate the OPR retry function (set value: 1). (Refer to

Section 13.2.1).

• Move the work piece from the current position (on OP) using

the manual control operation (refer to Chapter 11), then carry

out a machine OPR again.

74+150n

75+150n

<OPR speed>

1 to 1000000000 [PLS/s]

1 to 2000000000 [

10

-2

mm/min or others]

• Lower the OPR speed.

• Increase the dog signal input time.

(Refer to Section 8.2.3)

80+150n

81+150n

<Movement amount setting after near-

point dog ON>

0 to 2147483647

• Calculate the movement distance using a speed limit, OPR

speed, and deceleration time, and set the movement amount

after near-point dog ON so that the distance becomes a

deceleration distance or longer.

• Lower the OPR speed.

• Adjust the near-point dog position so that the movement

amount after near-point dog ON becomes longer. (Refer to

Section 8.2.4, 8.2.5)

74+150n

75+150n

<OPR speed>

1 to 1000000000 [PLS/s]

1 to 2000000000 [

10

-2

mm/min]

1500+100n 4300+100n

<Positioning start No.>

1 to 600, 7000 to 7004, 9001 to 9004

Execute the machine OPR (positioning start No. 9001). (Refer

to Section 8.2)

1500+100n 4300+100n

<Positioning start No.>

1 to 600, 7000 to 7004, 9001 to 9004

Start the machine OPR (positioning start No. 9001) again.

(Refer to Section 8.2)

— — —

Turn the motor more than one revolution using JOG or

positioning operation.

— — —

• Execute OPR again.

• When the servo parameter "Function selection C-4 (PC17)"

is changed to "1: Not need to pass servo motor Z-phase after

power on", transfer the parameter from the Simple Motion

module to the servo amplifier and turn the power supply of

the servo amplifier OFF. Then, turn it ON and execute OPR

again.

n: Axis No.-1