14 - 38

Chapter 14 Common Functions

[MR-J4-_B use]

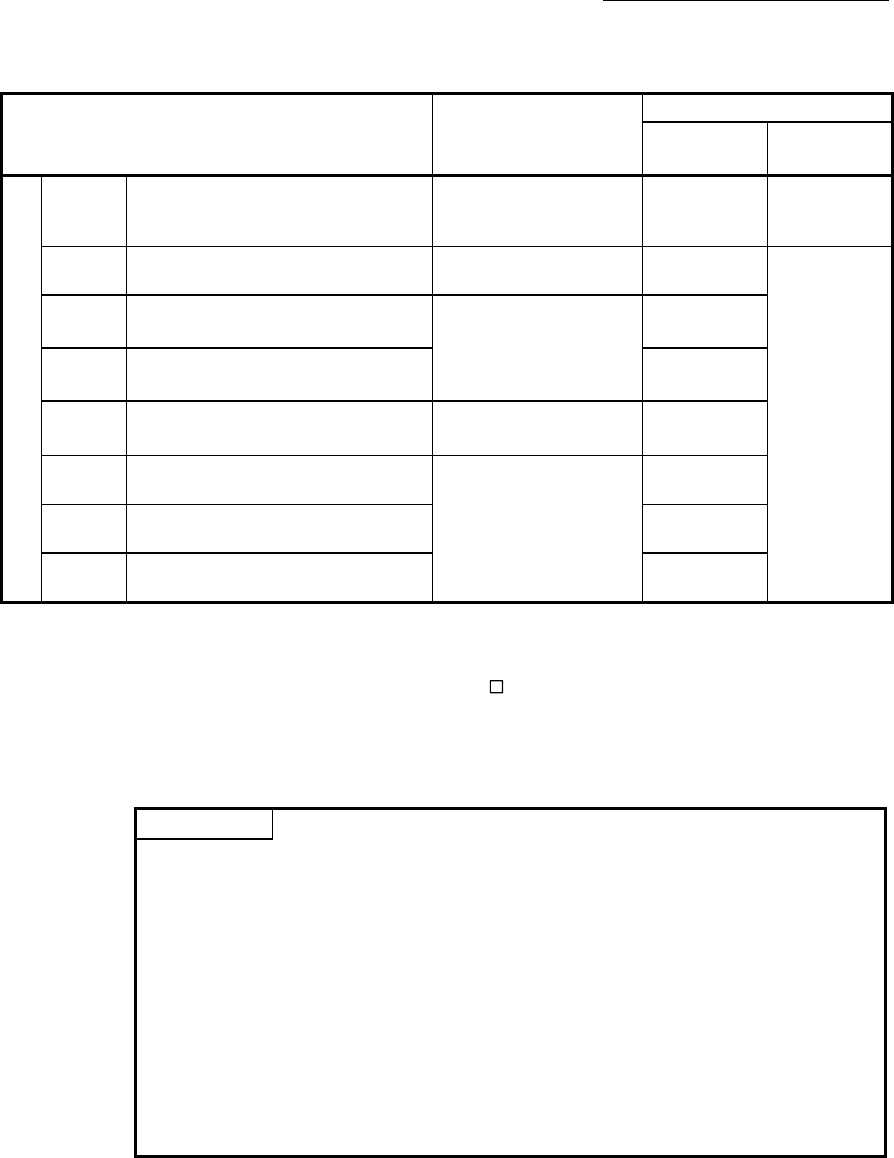

Setting item Setting details

Buffer memory address

QD77MS2

QD77MS4

QD77MS16

Input/output setting

PA04

Forced stop deceleration function

selection

Disable deceleration stop

function at the master

axis and slave axis.

30104+200n 28404+100n

PD15

Driver communication setting

Set the master axis and

slave axis.

30210+200n

Set with

GX Works2

PD16

Driver communication setting

Master transmit data selection 1

Set the transmitted data

at master axis setting.

30211+200n

PD17

Driver communication setting

Master transmit data selection 2

30212+200n

PD20

Driver communication setting

Master axis No. selection 1 for slave

Set the axis No. of master

axis at slave axis setting.

30215+200n

PD30

Master-slave operation - Torque

command coefficient on slave

Set the parameter at

slave axis setting.

30225+200n

PD31

Master-slave operation - Speed limit

coefficient on slave

30226+200n

PD32

Master-slave operation - Speed limit

adjusted value on slave

30227+200n

n: Axis No.-1

(Note-1): When the slave axis is not allocated for the master axis, the operation is normal operation only of

master axis.

(Note-2): For QD77MS16, the above servo parameters of PD

are not allocated to the buffer memory.

Write them to Simple Motion module with GX Works2.

(Note-3): At slave setting, set only "Driver communication setting Master axis No. selection 1 for slave (PD20)" in

the master axis No. selection normally.

POINT

(1) The servo parameters are transmitted from Simple Motion module to servo

amplifier after power supply ON or reset of PLC CPU. Execute flash ROM

writing of Simple Motion module after writing the servo parameter to buffer

memory, and then turn the power supply ON or reset the PLC CPU.

(2) The servo parameters for driver communication setting (PA04, PD15 to PD17,

PD20) become valid by turning the servo amplifier's power supply OFF to ON.

Turn the servo amplifier's power supply OFF to ON after executing the above

(1). Then, turn the system's power supply ON or reset the PLC CPU.

(3) In the driver communication function, the torque generation direction for slave

axis can be set in "Rotation direction selection/travel direction selection

(PA14)".