1 - 7

Chapter 1 Product Outline

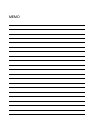

Lifter

Servo

amplifier

Servomotor

Aging rack

Lifter

Counter-

weight

A conveyor

Servo

amplifier

Reduction

gear

Servomotor

(with a brake)

QD77MS

B conveyor

C conveyor

G2

G1

Loader/unloader

Unloader

Loader

During the aging process, storage onto the

rack is carried out by positioning with the AC

servo.

The up/down positioning of the lifter is carried

out with the 1-axis servo, and the horizontal

position of the aging rack is positioned with the

2-axis servo.

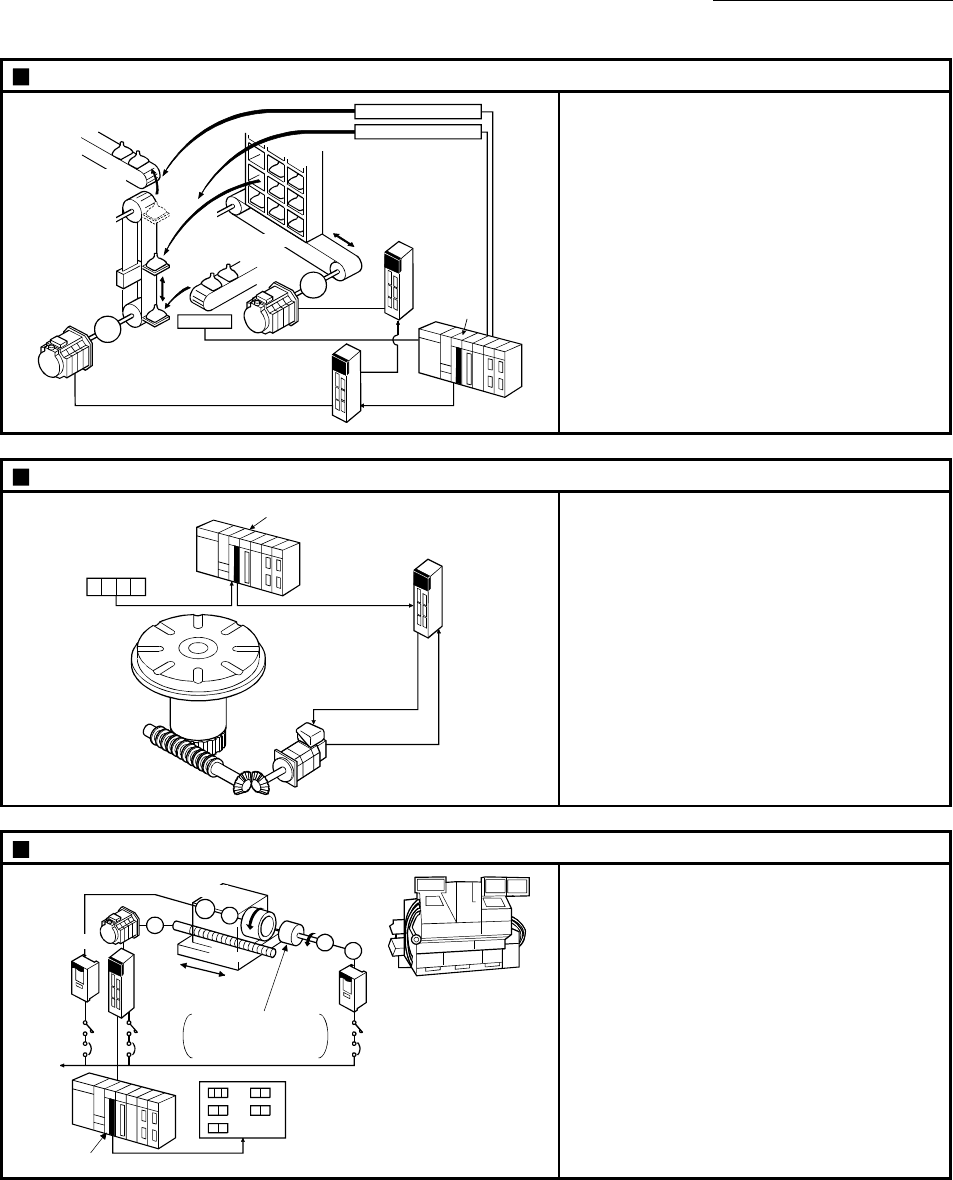

Index table (High-accuracy indexing of angle)

Detector

Servomotor

Worm gears

Index table

Digital switch

Servo

amplifie

r

QD77MS

The index table is positioned at a high accuracy

using the 1-axis servo.

Inner surface grinder

QD77MS

Servomotor

Servo

amplifier

220VAC

60Hz

Inverter

Grinding stone

Workpiece

Motor

Fix the grinding

stone, feed the

workpiece, and grind.

Operation panel

a. Total feed

amount (m)

b. Finishing

feed amount (m)

c. Compensation

amount (

m)

d. Rough grind-

ing speed (

m/s)

e. Fine grinding

speed (m/s)

Inverter

G

IM

G

a

b

c

d

e

Motor

IM

G

The grinding of the workpiece's inner surface

is controlled with the servo and inverter.

The rotation of the workpiece is controlled with

the 1-axis inverter, and the rotation of the

grinding stone is controlled with the 2-axis

inverter. The workpiece is fed and ground with

the 3-axis servo.