1 - 29

Chapter 1 Product Outline

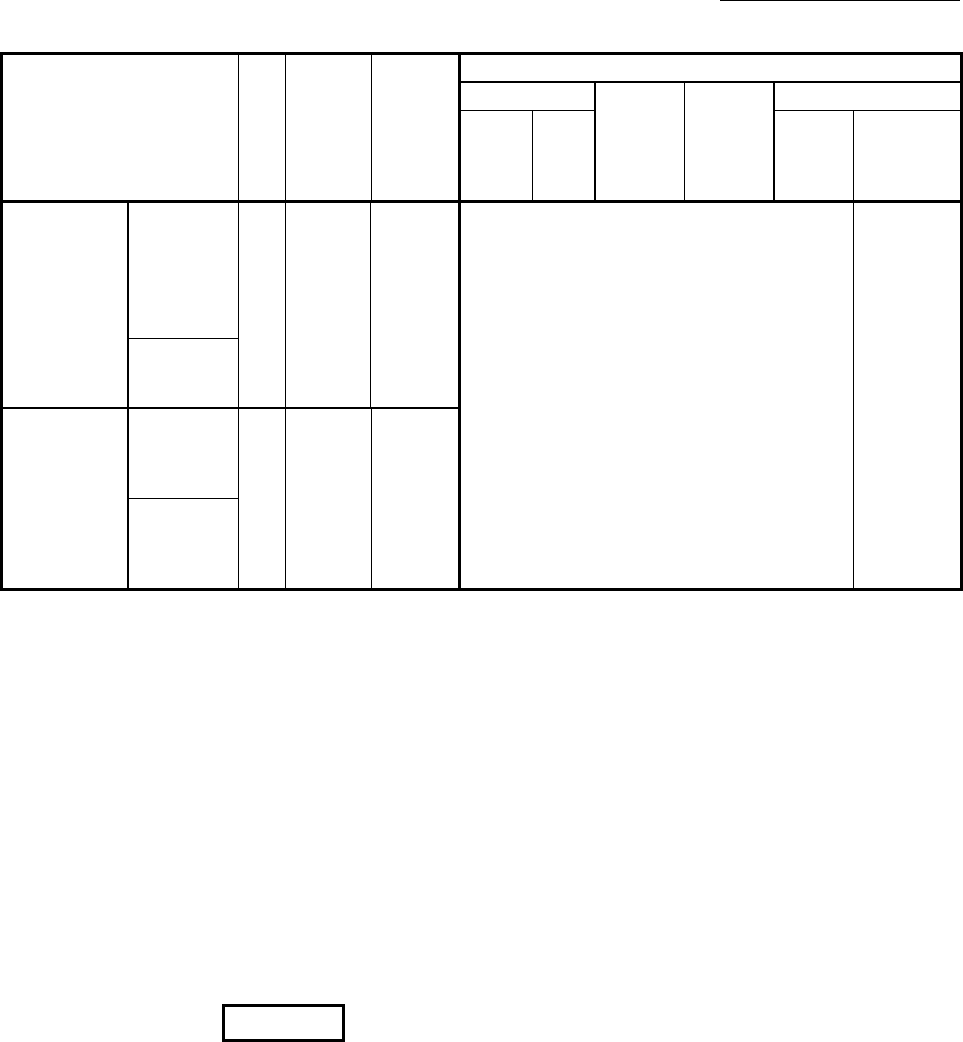

Stop cause

Stop

axis

M code

ON signal

after stop

Axis

operation

status

after

stopping

([Md.26])

Stop process

OPR control

Major

positioning

control

High-level

positioning

control

Manual control

Machine

OPR

control

Fast

OPR

control

JOG/

Inching

operation

Manual

pulse

generator

operation

Relatively safe

stop

(Stop group 3)

Axis error

detection

(Error other

than stop

group 1 or 2)

(Note-1)

Each

axis

No

change

Error

Deceleration stop/sudden stop

(Select with "[Pr.39] Stop group 3 sudden stop

selection".)

Deceleration

stop

"Stop" input

from

GX Works2

Intentional stop

(Stop group 3)

"Axis stop

signal" ON

from PLC

CPU

Each

axis

No

change

Stopped

(Standby)

"Stop signal"

of external

input signal

ON

(Note-1): If an error occurs in a positioning data due to an invalid setting value, when the continuous positioning control uses multiple

positioning data successively, it automatically decelerates at the previous positioning data. It does not stop suddenly even the

setting value is sudden stop in stop group 3. If any of the following error occurs, the operation is performed up to the positioning

data immediately before the positioning data where an error occurred, and then stops immediately.

• No command speed (Error code: 503)

• Outside linear movement amount range (Error code: 504)

• Large arc error deviation (Error code: 506)

• Software stroke limit + (Error code: 507)

• Software stroke limit - (Error code: 508)

• Sub point setting error (Error code: 525)

• End point setting error (Error code: 526)

• Center point setting error (Error code: 527)

• Outside radius range (Error code: 544)

• Illegal setting of ABS direction in unit of degree (Error code: 546)

REMARK

Provide the emergency stop circuits outside the servo system to prevent cases

where danger may result from abnormal operation of the overall system in the event

of an external power supply fault or servo system failure.