13 - 63

Chapter 13 Control Sub Functions

[3] Method of setting target position change function from PLC CPU

The following table and chart show the example of a data setting and sequence

program used to change the target position of the axis 1 by the command from

the PLC CPU, respectively. (example in which the target position value and

command speed are changed to a new target position of "300.0

m" and a new

command speed of "10000.00 mm/min".)

(1) The following data is set.

(Referring to the target position change time chart shown in item (2) below,

carry out the setting with the sequence program shown in item (3).)

Setting item

Setting

value

Setting details

Buffer memory address

QD77MS2

QD77MS4

QD77MS16

[Cd.27]

Target position

change value

(New address)

3000 Set the new address.

1534+100n

1535+100n

4334+100n

4335+100n

[Cd.28]

Target position

change value

(New speed)

1000000 Set the new speed.

1536+100n

1537+100n

4336+100n

4337+100n

[Cd.29]

Target position

change request

flag

1

Set "1: Requests a change in the target

position".

1538+100n 4338+100n

n: Axis No.-1

: Refer to Section 5.7 "List of control data" for details on the setting details.

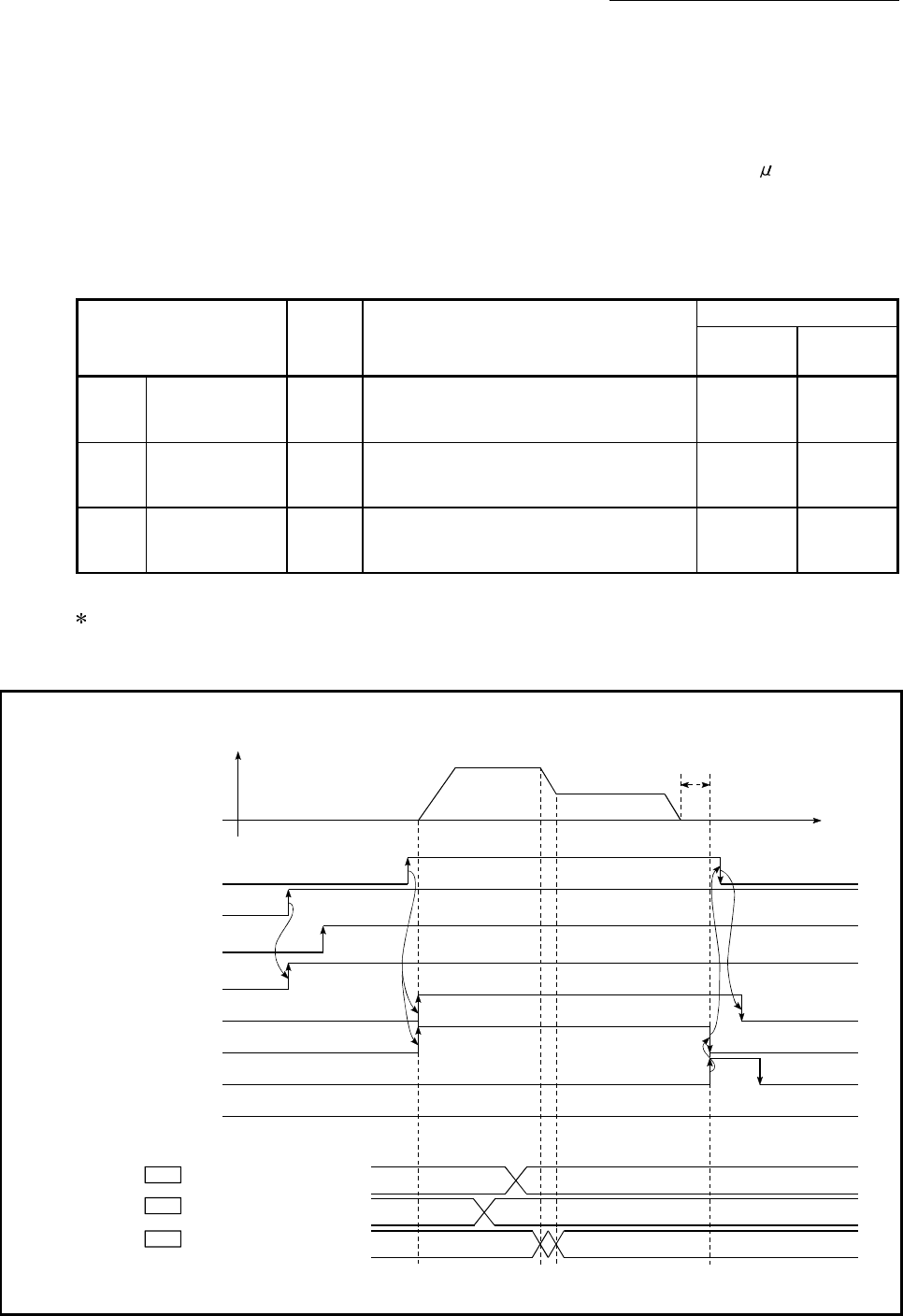

(2) The following shows the time chart for target position change.

[QD77MS4 operation example]

PLC READY signal [Y0]

READY signal [X0]

Start complete signal [X10]

BUSY signal [XC]

Error detection signal [X8]

V

t

Positioning start signal [Y10]

1000000

3000

Positioning complete signal [X14]

Dwell time

Cd.27

Cd.28

1

0

0

Cd.29

All axis servo ON [Y1]

Target position change value

(New address)

Target position change value

(New speed)

Target position change request

flag

(Note): Refer to Section 3.3 for input/output signal of QD77MS16.

Fig. 13.34 Time chart for target position change from PLC CPU