6

Modules Section 1-3

FQM1-TER01 End Module One End Module is supplied with the Coordinator Module. Always attach the

End Module because it acts as a terminator for the system. A fatal error will

occur if no End Module is attached.

Other Peripheral Devices Special Servo Relay Units are available for connecting the FQM1 Flexible

Motion Control system to OMRON W-series and SMARTSTEP Servo Drivers.

Specific cables suitable for the connected Servomotor/Servo Driver models

and the FQM1 Motion Control Module models are also available.

1-3 Modules

The Coordinator Module acts as the interface between the FQM1 system and

peripheral devices, shares data with each Motion Control Module, and syn-

chronizes specific data (e.g., virtual axis data) between Modules.

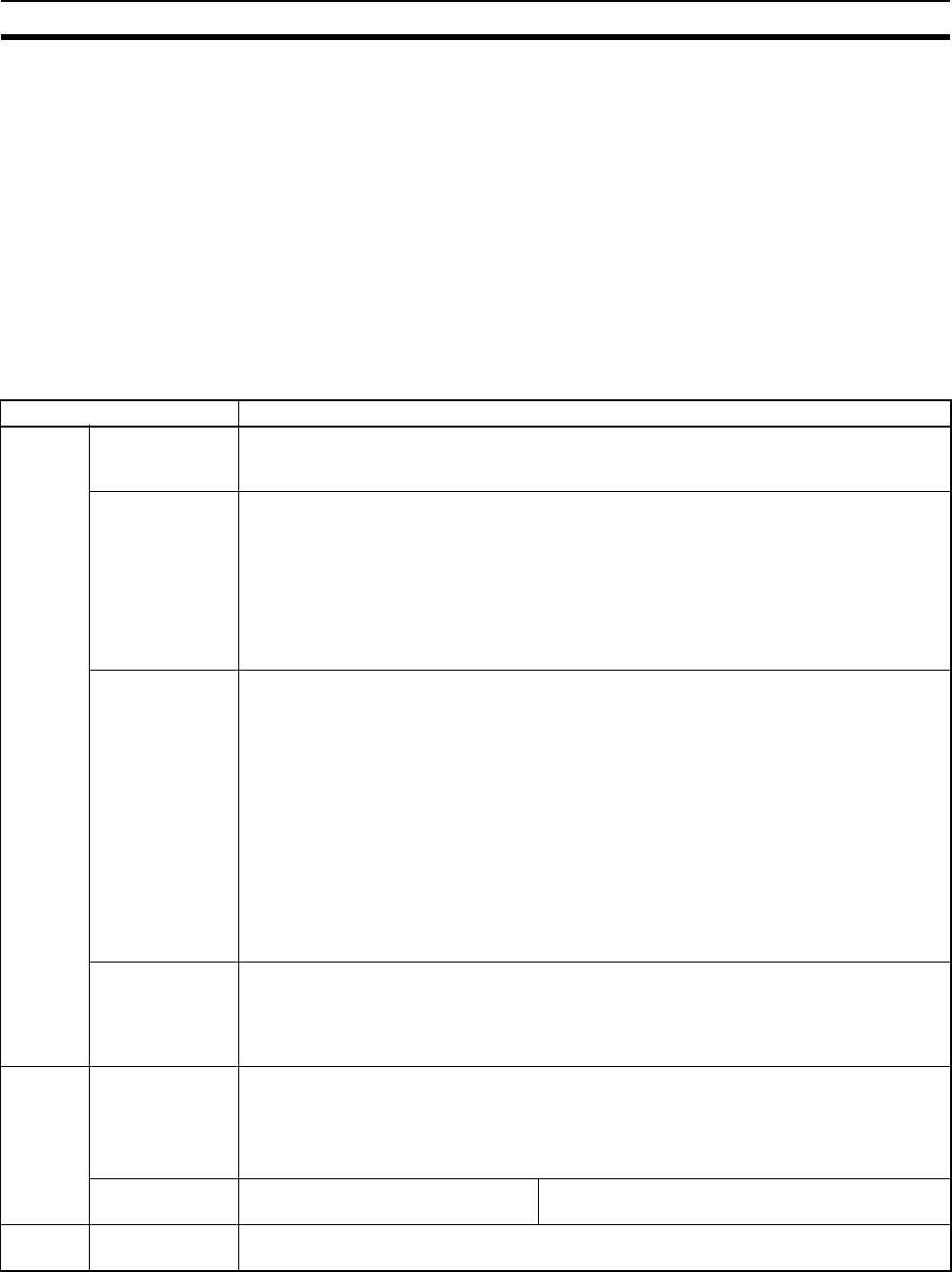

Item Details

Functions Interfaces for

peripheral

devices

Connection with the CX-Programmer (peripheral port)

Connection with PT for monitoring and parameter settings (RS-232C port)

Connections with Servo Drivers (RS-422A port)

Sharing data with

each Motion

Control Module

(each Coordina-

tor Module cycle)

The 10 words are allocated for each Motion Control Module in the Cyclic Refresh Bit Area

of the Coordinator Module (CIO 0100 to CIO 0139), based on the Motion Control Module

slot number. These words correspond to CIO 0100 to CIO 0109 in the Cyclic Refresh Bit

Area of each Motion Control Module.

• Coordinator Module to Motion Control Module: 5 words (General-purpose output)

• Motion Control Module to Coordinator Module: 5 words (General-purpose input: 4 words,

program RUN, fatal errors, non-fatal errors)

This cyclic refresh data is refreshed every Coordinator Module cycle.

Synchronized

sharing of special

data between

Modules (broad-

cast at specified

sync cycle)

User-specified synchronous data (see following list) can be allocated to CIO 0200 to CIO

0219 in the Synchronous Data Link Bit Area of the Coordinator Module and each Motion

Control Module, 4 words at a time (2 types of data × 2 words). The allocations are fixed,

starting with the Coordinator Module and followed by Motion Control Modules in order of

slot number.

• Any ladder program data

• High-speed counter PV

• Pulse output PV

• Analog input PV

• Analog output PV

• Built-in I/O input values

The synchronous data is broadcast each specified sync cycle and all other Modules

receive this data in essentially real-time.

DM data transfer

with specific

Motion Control

Modules (as

required)

DM data (499 words max.) can be transferred in the specified direction between the speci-

fied words in the DM Area in the specified Motion Control Module and the specified DM

Area words in the Coordinator Module when the DM Write Request Bit (A530.00) or DM

Read Request Bit (A530.01) in the Auxiliary Area of the Coordinator Module turns ON.

I/O Serial communi-

cations

• Peripheral port: Peripheral bus (for CX-Programmer)

• One RS-232C port: NT Link (for OMRON PTs), Host Link (for host computers), or no pro-

tocol (for PLCs)

• One RS-422A port (Same connector as general-purpose I/O): 1:N communications with

Servo Drivers (for transferring parameters to Servo Drivers)

General-purpose

I/O

General-purpose inputs: 16

General-purpose outputs: 8

40-pin connector (including RS-422A)

Programs Program capacity 5 Ksteps (for data exchange with host computer, coordination of Motion Control Modules,

and other peripheral programming)