95

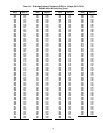

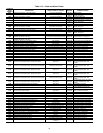

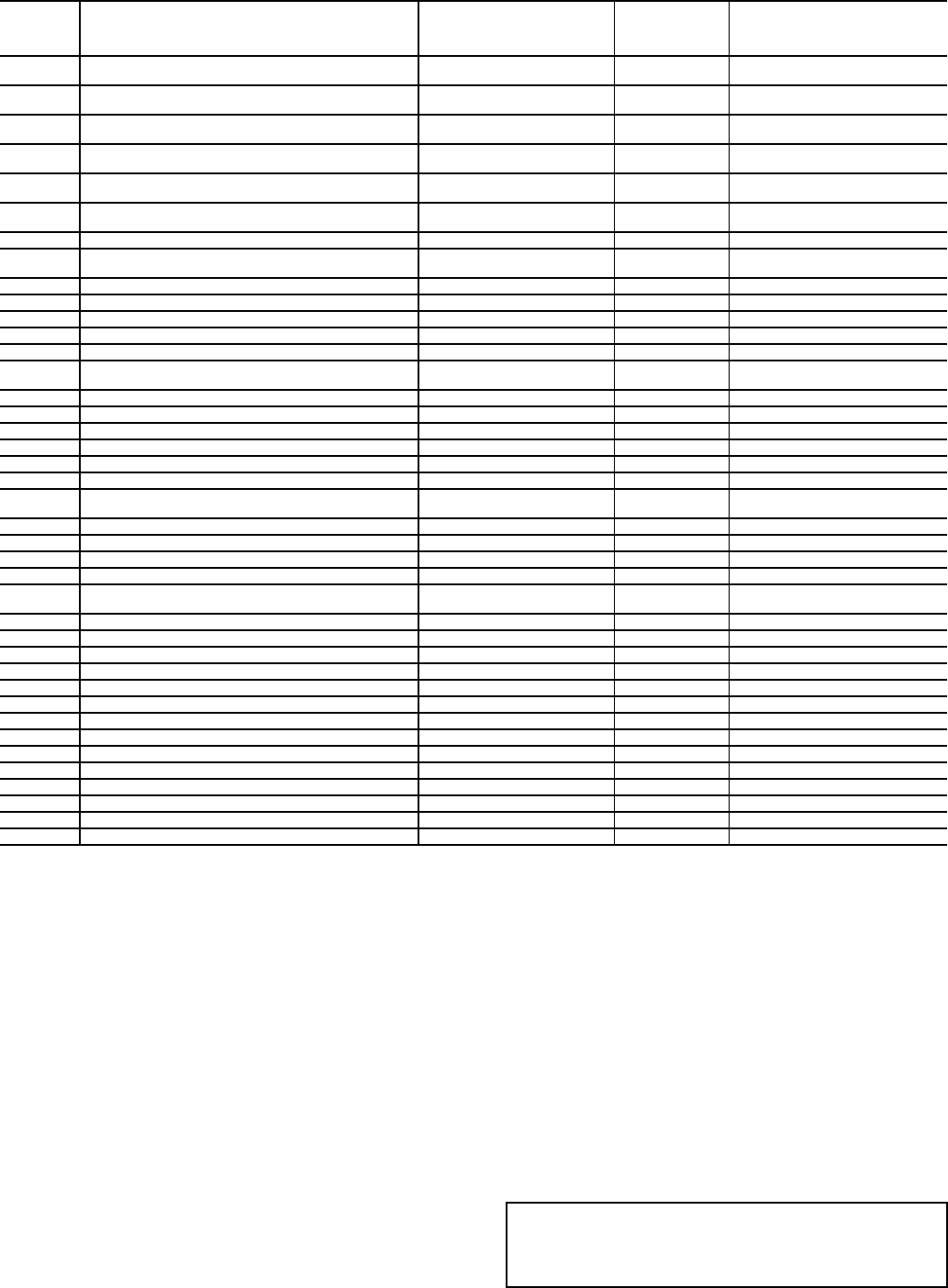

Table 114 — Alert and Alarm Codes (cont)

LEGEND

For 48/50A2,A3,A4,A5 units:

• Compressor internal overload protector is open. Internal

overload protectors are used in the Copeland compressors in

all units except size 60 ton units with voltages of 208/230-v,

380-v, and 575-v.

• Compressor external overload protector (Kriwan module)

has activated. The Copeland compressors in size 60 ton

units with voltages of 208/230-v, 380-v, and 575-v use

external overload protector modules that are mounted in the

compressor wiring junction box. Temperature sensors

embedded in the compressor motor windings are the inputs

to the module. The module is powered with 120 vac from

the units main control box. The module output is a normally

closed contact that is wired in series with the compressor

contactor coil. In a compressor motor overload condition,

the contact opens de-energizing the compressor contactor.

• Circuit breaker trip. The compressors are protected from

short circuit by a breaker in the control box. On the 020-050

size units there is one breaker per two compressors and on

the 060 size units there is one breaker per compressor.

• Wiring Error. A wiring error might not allow the compres-

sor to start.

To check out alerts 051, 052, 055 and 056:

1. Turn on the compressor in question using Service Test

mode. If the compressor does not start, then most likely

the problem is one of the following: HPS open, open

internal protection, circuit breaker trip, incorrect safety

wiring, or incorrect compressor wiring.

2. If the compressor does start verify it is rotating in the

correct direction.

ALARM

OR

ALERT

NUMBER

DESCRIPTION ACTION TAKEN BY CONTROL

RESET

METHOD

PROBABLE CAUSE

T300 Space Temperature Below Limit

Stop cooling, but continue

to heat

Automatic Outdoor dampers stuck, no load

T301 Space Temperature Above Limit

Stop heating, but continue

to cool

Automatic High load, dampers open

T302 Supply Temperature Below Limit Continue to run unit Automatic

Dampers open, check configuration

setpoint

T303 Supply Temperature Above Limit Continue to run unit Automatic

Dampers open, check configuration

setpoint

T304 Return Temperature Below Limit Continue to run unit Automatic

Dampers open, check configuration

setpoint

T305 Return Temperature Above Limit Continue to run unit Automatic

Dampers open, check configuration

setpoint

T308 Return Air Relative Humidity Below Limit Alert Automatic Configuration error, or sensor error

T309 Return Air Relative Humidity Above Limit Continue to run unit Automatic

Dampers open, check configuration

setpoint

T310 Supply Duct Static Pressure Below Limit Continue to run unit Automatic VFD problem, broken fan belt

T311 Supply Duct Static Pressure Above Limit Continue to run unit Automatic VFD problem, broken fan belt

T312 Building Static Pressure Below Limit Continue to run unit Automatic Exhaust issues, check setpoint

T313 Building Static Pressure Above Limit Continue to run unit Automatic Exhaust issues, check setpoint

T314 IAQ Above Limit Continue to run unit Automatic Damper or IAQ control issues

A404 Fire Shut Down Emergency Mode (fire-smoke) Unit Shutdown Automatic

Smoke detector switch or external

switch

A405 Evacuation Emergency Mode Run power exhaust Automatic Special fire mode control

A406 Pressurization Emergency Mode Run supply fan Automatic Special fire mode control

A407 Smoke Purge Emergency Mode Run supply and exhaust fans Automatic Special fire mode control

T408 Dirty Air Filter Continue to run unit Automatic Dirty filter, switch setting

A409 Supply Fan Status Failure Stop unit Automatic Fan drive failure

T409 Supply Fan Status Failure Continue to run unit Automatic Fan drive failure, or sensor failure

T414 Loss of Communication with the Belimo Actuator Close economizer Automatic

Calibrate economizer, economizer

failure, wiring

T414 Belimo Actuator Direction Error Close economizer Automatic Motor direction switch wrong, wiring

T414 Belimo Actuator Failure Attempt to close economizer Automatic Motor failure

T414 Belimo Actuator Jammed Close economizer Automatic Obstruction in damper

T414 Belimo Actuator Range Error Close economizer Automatic Calibrate economizer

T420

R-W1 Jumper Must Be Installed to Run Heat in Service

Te st

No heat Automatic Add red wire jumpers

T421 Thermostat Y2 Input ON without Y1 ON Assume Y2 is Y1 Automatic Thermostat wiring error

T422 Thermostat W2 Input ON without W1 ON Assume W2 is W1 Automatic Thermostat wiring error

T423 Thermostat Y and W Inputs ON Alert Automatic Thermostat issues

T424 Thermostat G Input OFF on a Call for Cooling Turn fan on Automatic Thermostat or wiring issues

T500 Current Sensor Board Failure - A1 Stop compressor A1 Automatic Faulty board or wiring

T501 Current Sensor Board Failure - A2 Stop compressor A2 Automatic Faulty board or wiring

T502 Current Sensor Board Failure - B1 Stop compressor B1 Automatic Faulty board or wiring

T503 Current Sensor Board Failure - B2 Stop compressor B2 Automatic Faulty board or wiring

A700

Supply Air Temperature Sensor Failure Stop staged gas heat Automatic Faulty sensor or wiring error

T701 Staged Gas Thermistor 1 Failure Stop staged gas heat Automatic Faulty sensor or wiring error

T702 Staged Gas Thermistor 2 Failure Stop staged gas heat Automatic Faulty sensor or wiring error

T703 Staged Gas Thermistor 3 Failure Stop staged gas heat Automatic Faulty sensor or wiring error

A704 Staged Gas Leaving Air Temp Sum Total Failure Stop staged gas heat Automatic Faulty sensor or wiring error

T705 Limit Switch Thermistor Failure Stop staged gas heat Automatic Faulty switch or wiring

Axxx — Alarm Pxxx — Pre-Alert

CEM — Controls Expansion module Txxx — Alert

IAQ — Indoor Air Quality TXV — Thermostatic Expansion Valve

OAT — Outdoor Air Temperature VFD — Variable Frequency Drive

IMPORTANT: Prolonged operation in the wrong direction

can damage the compressor. Correct rotation can be veri-

fied by a gage set and looking for a differential pressure

rise on start-up.