124

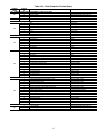

BOARD ADDRESSES — Each board in the system has an

address. The MBB has a default address of 1 but it does have

an instance jumper that should be set to 1 as shown in Fig. 26.

For the other boards in the system there is a 4-dip switch head-

er on each board that should be set as shown below.

0 = On; 1 = Off

FIELD CONNECTION TERMINAL STRIPS — Field con-

nection terminal strips are located in the main control box. See

Fig. 32 and Table 122.

Accessory Control Components — In addition to

the factory-installed options, the units can also be equipped

with several field-installed accessories that expand the control

features of the unit. The following hardware components can

be used as accessories.

ROOM THERMOSTATS (48/50AJ,AW,A2,A4 UNITS

ONLY) — The ComfortLink™ controls support a conven-

tional electro-mechanical or electronic thermostat that uses the

Y1, Y2, W1, W2, and G signals. The control also supports an

additional input for an occupied/unoccupied command that is

available on some new thermostats. The ComfortLink controls

can be configured to run with multiple stages of capacity which

allows up to 6 stages of capacity. Although the unit can be con-

figured for normal 2-stage control, it is recommended that the

multi-stage control be used. The room thermostat is connected

to TB4.

SPACE SENSOR — The ComfortLink controls support the

use of space temperature sensors. The T55 and T56 sensors

and CCN communicating T58 room sensor can be used. The

T55 and T56 sensors are connected to TB5 terminal 3, 4, and 5.

The T58 sensor is connected to the CCN connections on TB3.

When a T55, T56, or T58 sensor is used, the user must install

the red jumpers from R to W1, and W2 on TB4 for the heat

function to work correctly.

SPACE CO

2

SENSORS — The ComfortLink controls also

support a CO

2

IAQ sensor that can be located in the space for

use in demand ventilation. The sensor must be a 4 to 20 mA

sensor and should be connected to TB5 terminal 6 and 7. See

Fig. 33 for sensor wiring.

ECONOMIZER HUMIDITY CHANGEOVER SEN-

SORS — The ComfortLink controls support 5 different

changeover schemes for the economizer. These are:

• outdoor air dry bulb

• differential dry bulb

• outdoor air enthalpy curves

• differential enthalpy

• custom curves (a combination of an enthalpy/dewpoint

curve and a dry bulb curve).

The units are equipped as standard with an outside air and

return air dry bulb sensor which supports the dry bulb change-

over methods. If the other methods are to be used, then a field-

installed humidity sensor must be installed for outdoor air en-

thalpy and customer curve control and two humidity sensors

must be installed for differential enthalpy. Installation holes are

pre-drilled and wire harnesses are installed in every unit for

connection of the humidity sensors. The ComfortLink controls

convert the measured humidity into enthalpy, dewpoint, and

the humidity changeover curves.

MOTORMASTER

®

V CONTROL — For operation below

32 F when an economizer is not used, the units can be equipped

with an accessory Motormaster V control, which controls the

speed of the stage 1 condenser fans. The Motormaster V control

is a 3-phase inverter that controls the speed of the fans based on

a pressure transducer connected to the liquid line. On 48/

50A020-035 units, one fan will be controlled. On 48/50A036-

060 units, two fans will be controlled. For units equipped with

an economizer, there should not be a need for this control be-

cause the economizer can provide free cooling using outside air,

which will be significantly lower in operating cost.

The accessory Motormaster V speed control is a completely

self-contained control and is not controlled by the unit’s

ComfortLink controller. On 48/50A051 and 060 units with 6

fan motors, the Motormaster control configuration (M.M.)

must be set to YES. See page 39.

ACCESSORY NAVIGATOR™ DISPLAY — The accesso-

ry handheld Navigator display can be used with the 48/50A se-

ries units. See Fig. 34. The Navigator display operates the same

way as the scrolling marquee device. The ECB1 and ECB2

boards contain a second LEN port (J3 connection) than can be

used with the handheld Navigator display.

CONTROL MODULE COMMUNICATIONS

Red LED

— Proper operation of the control boards can be

visually checked by looking at the red status LEDs as shown on

Fig. 26-29. When operating correctly, the red status LEDs

should blink in unison at a rate of once every 2 seconds. If the

red LEDs are not blinking in unison, verify that correct power is

being supplied to all modules. Also, be sure that the main base

board is supplied with the current software. If necessary, reload

current software. If the problem still persists, replace the MBB.

A board LED that is lit continuously or blinking at a rate of once

per second or faster indicates that the board should be replaced.

BOARD SW1 SW2 SW3 SW4

ECB10000

ECB21000

SCB0000

CEM0000

13579111315

246810121416

12345678

R Y1Y2W1W2G C X

13579111315

246810121416

TB5

TB6

TB3

TB4

C

LEN

CCN

CCN

+

-

GRD

Fig. 32 — Field Connection Terminal Strips (Main Control Box)

A48-7081