78

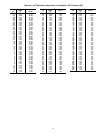

Transducer Troubleshooting — On 48/50AJ,AK,

AW,AY units, the electronic control uses 2 suction pressure

transducers to measure the suction pressure of circuits A and B.

The pressure/voltage characteristics of these transducers are in

shown in Tables 101 and 102. On 48/50A2,A3,A4,A5 units,

the electronic control uses 4 pressure transducers to measure

the suction and discharge pressure of circuits A and B. The

pressure/voltage characteristics of these transducers are shown

in Tables 103 and 104. The accuracy of these transducers can

be verified by connecting an accurate pressure gage to the sec-

ond refrigerant port in the suction line.

Table 94 — Cooling Service Analysis

LEGEND

PROBLEM SOLUTION

COMPRESSOR DOES NOT RUN

Active Alarm

Check active alarms using local display.

Contactor Open

1. Power off. 1. Restore power.

2. Fuses blown in field power circuit. 2. After finding cause and correcting, replace with correct size fuse.

3. No control power. 3. Check secondary fuse(s); replace with correct type and size.

Replace transformer if primary windings receiving power.

4. Compressor circuit breaker tripped. 4. Check for excessive compressor current draw. Reset breaker;

replace if defective.

5. Safety device lockout circuit active. 5. Reset lockout circuit at circuit breaker.

6. High-pressure switch open. 6. Check for refrigerant overcharge, obstruction of outdoor airflow, air

in system or whether compressor discharge valve is fully open. Be

sure outdoor fans are operating correctly.

7. Loose electrical connections. 7. Tighten all connections.

Contactor Closed

1. Compressor leads loose. 1. Check connections.

2. Motor windings open. 2. See compressor service literature.

3. Single phasing. 3. Check for blown fuse. Check for loose connection at compressor

terminal.

4. ASTP activated (48/50A2,A3,A4,A5 only) 4. Allow 30 to 120 minutes for cool down. See Compressor Safeties

section on page 39.

COMPRESSOR STOPS ON HIGH PRESSURE

Outdoor Fan On

1. High-pressure switch faulty. 1. Replace switch.

2. Airflow restricted. 2. Remove obstruction.

3. Air recirculating. 3. Clear airflow area.

4. Noncondensables in system. 4. Purge and recharge as required.

5. Refrigerant overcharge. 5. Purge as required.

6. Line voltage incorrect. 6. Consult power company.

7. Refrigerant system restrictions. 7. Check or replace filter drier, expansion valve, etc. Check that

compressor discharge valve is fully open.

8. Fan running in reverse direction. 8. Correct wiring.

Outdoor Fan Off

1. Fan slips on shaft. 1. Tighten fan hub setscrews.

2. Motor not running. 2. Check power and capacitor.

3. Motor overload open. 3. Check overload rating. Check for fan blade obstruction.

4. Motor burned out. 4. Replace motor.

COMPRESSOR CYCLES ON LOW PRESSURE

Indoor-Air Fan Running

1. Filter drier plugged. 1. Replace filter drier.

2. Expansion valve power head defective. 2. Replace power head.

3. Low refrigerant charge. 3. Add charge.

4. Faulty pressure transducer.

4. Check that pressure transducer is connected and secured to suc-

tion line. If still not functioning, replace transducer.

Airflow Restricted

1. Coil iced up. 1. Check refrigerant charge.

2. Coil dirty. 2. Clean coil fins.

3. Air filters dirty. 3. Clean or replace filters.

4. Dampers closed. 4. Check damper operation and position.

Indoor-Air Fan Stopped

1. Electrical connections loose. 1. Tighten all connections.

2. Fan relay defective. 2. Replace relay.

3. Motor overload open. 3. Power supply.

4. Motor defective. 4. Replace motor.

5. Fan belt broken or slipping. 5. Replace or tighten belt.

ASTP — Advanced Scroll Temperature Protection

VFD — Variable Frequency Drive