124

Epsilon EP-I Indexing Drive and FM-2 Indexing Module Reference Manual

Encoder signals are used for commutation. Incorrectly wired encoder signals can cause damage to the drive.

Step 3:Determine Encoder Alignment

In order for the drive to commutate with a motor correctly, it must know how the encoder commutation tracks and how the

marker pulses are aligned with respect to the R, S and T windings in the stator. The drive does not require any particular

alignment position but instead allows the alignment to be specified using the Motor Encoder U Angle and Motor Encoder

Marker Angle parameters.

If the motor under test has a defined encoder alignment which is repeated on all similar motors, simply determine the proper

angles then use the same settings on all similar motors.

If the motor under test does not have a specific encoder alignment, you should establish some standard mechanical alignment

before determining and setting the encoder electrical angles. This will allow you to replace the motor with another one in the

same alignment without going through this procedure each time.

Reading Encoder Alignment

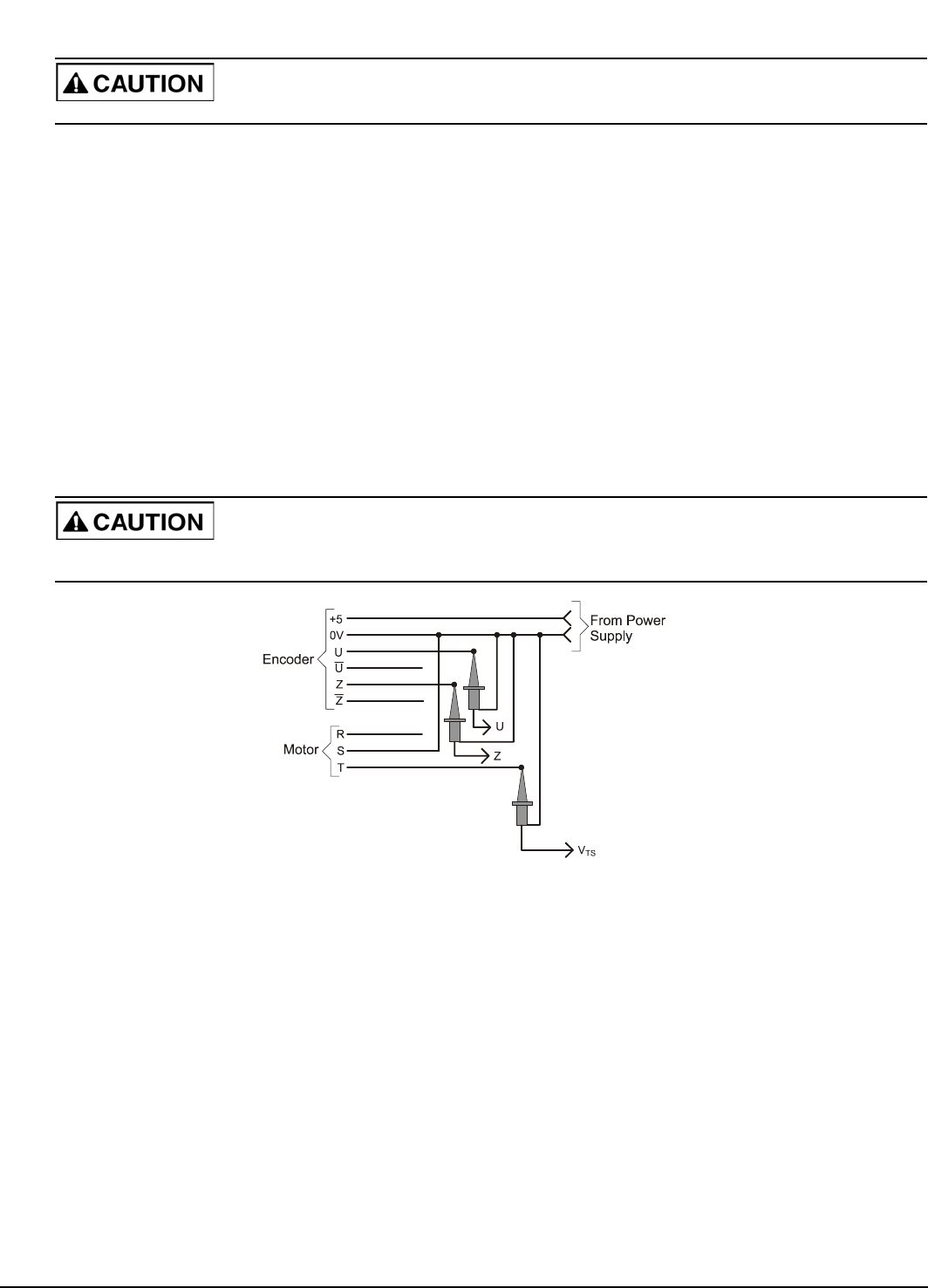

The reference motion for this test can be either CW or CCW. We will first use CCW. An oscilloscope will be used to monitor

the signals. This procedure must be performed with the motor disconnected from the drive with the exception of the encoder

power supply.

Be careful when using the drive encoder power supply for testing a motor. Shorting the 5V drives encoder power supply

will blow an internal fuse which can only be replaced at the factory.

Figure 111: Oscilloscope Connections

CCW Reference Rotation

Before reading the motor signals, zero the V

TS

oscilloscope channel on a horizontal graduation marker to allow more accurate

readings.

Couple the drill motor to the motor shaft. While spinning the motor counter-clockwise, use an oscilloscope to examine the

phase relationship between encoder channel U and positive peak of V

TS

(the voltage at motor power terminal T with reference

to S).

Use the figure below to determine the electrical angle at which the rising edge of U occurs. This is the Motor Encoder U

Angle. Note that with a CCW reference rotation the positive peak of V

TS

is at zero electrical degrees and the electrical angle

decreases from left to right.