Meter to Flow Computer Communication Worksheet 330

Reference, Installation, and Operations Manual Meter setup and configuration worksheet

3-9000-743 Rev S June 2013

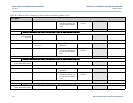

Analog Input

AI2 (Pressure)

User Selection (Circle one) Results (Enter Here)

Electrical Configuration • Sink • Source (i.e., powered by the meter) If the analog input is configured for

source mode, then it must be at the bottom of the loop (stack).

Pressure Type • gage • absolute

Atmospheric Pressure

(if absolute selected)

Minimum Input

(pressure corresponding to

4mA input)

• _____ psig

(if gage is selected)

• ______psia

(if absolute is selected)

Maximum Input

(pressure corresponding to

20mA input)

• ______psig • ______psia

Low Alarm • ______psig • ______psia

High Alarm • ______psig • ______psia

Note: If the pressure is at or outside these limits, an alarm is generated

Note: Pressure is required for optional meter internal diameter Pressure expansion correction. If a pressure transmitter is connected to the meter, select Live for this option. If a

pressure transmitter is not connected to the meter but pressure expansion correction is required, select Fixed. You will enter in a fixed pressure on a later page. If the correction is

not required, select Not used.

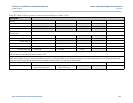

Digital Input

DI1

User Selection (Circle one) Results (Enter Here)

The Digital Input (DI1) may used to bring prover detector switches into the meter for “proving” against a ball prover (required only if input is used for

gated calibrations). Note: When using the digital method, the frequency output is not used for proving.

Calibration Type • Gated • Timed

Is DI1ForCalActiveLow • Active High • Active Low

Is DI1ForCalStateGated • Edge • State

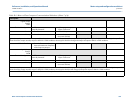

Table E-2 Meter to Flow Computer Communication Worksheet (Sheet 9 of 9)

Description