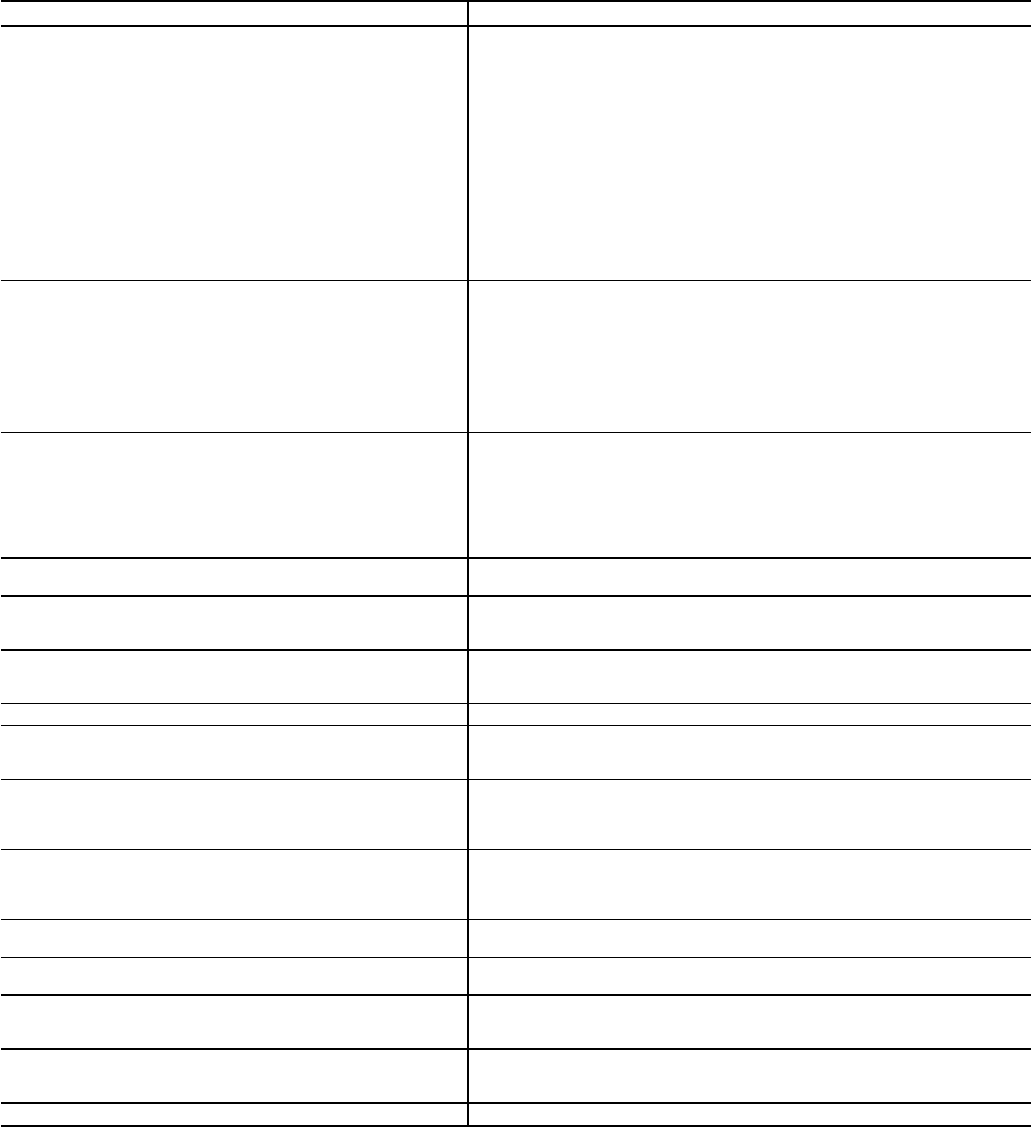

Table 12 — LID Primary and Secondary Messages and Custom Alarm/Alert Messages

with Troubleshooting Guides (cont)

N. OTHER PROBLEMS/MALFUNCTIONS

DESCRIPTION/MALFUNCTION PROBABLE CAUSE/REMEDY

Chilled Water/Brine Temperature

Too High (Chiller Running)

Chilled water set point set too high. Access set point on LID and verify.

Capacity overrideor excessivecooling load(chiller atdesign capacity).Check

LID statusmessages. Checkfor outsideair infiltrationinto conditionedspace.

Condenser temperature too high. Check for proper flow, examine cooling

tower operation, check for air or water leaks, check for fouled tubes.

Refrigerant level low. Check for leaks, add refrigerant, and trim charge.

Liquid bypass in waterbox. Examine division plates and gaskets for leaks.

Guide vanes fail to open. Use control test to check operation.

Chilled water control point too high. Access CONTROL ALGORITHM STA-

TUS table, MAINT01 screen, and check chilled water control operation.

Guide vanes failto open fully. Be sure thatthe guide vane targetis released.

Check guide vane linkage. Check limit switch in actuator.Check that sensor

is in the proper terminals.

Chilled Water/Brine Temperature Too Low (Chiller

Running)

Chilled water set point set too low. Access set point on LID and verify.

Chilled water control point too low. Access CONTROL ALGORITHM STA-

TUS tables, MAINT01 screen, and check chilled water control for proper

resets.

High discharge temperature keeps guide vanes open.

Guide vanes fail to close. Be sure that guide vane target is released. Check

chilled water sensor accuracy. Check guide vane linkage. Check actuator

operation.

Chilled Water Temperature Fluctuates. Vanes Hunt Deadbandtoonarrow.ConfigureLID foralargerdeadband (SERVICE1screen).

Proportional bandstoo narrow.Either

PROPORTIONALINC BAND

or

PRO-

PORTIONAL DEC BAND

should be increased (MAINT01 screen).

Loose guide vane drive. Adjust chain drive.

Defective vane actuator. Check using control test feature.

Defective temperature sensor. Check sensor accuracy.

Low Oil Sump Temperature While Running

(Less than 100 F [38 C])

Check for proper oil level (not enough oil).

AtPower Up,DefaultScreenDoes NotAppear,‘‘Tables Load-

ing’’ Message Continually Appears

Check for proper communications wiring on PSIO module. Check that the

COMM1 communications wires from the LID are terminated to the COMM1

PSIO connection. Check for ground or short on CCN system wiring.

SMM Communications Failure CheckthatPSIO communication plugsare connected correctly. CheckSMM

communication plug.Check forproper SMMpower supply. See ControlMod-

ules section on page 96.

High Oil Temperature While Running Check for proper oil level (too much oil). Check water supply to oil cooler.

Blank LID Screen (Minimal Contrast Visible) Increase contrast potentiometer. See Fig. 49. Check red LED on LID for

proper operation, (power supply). If LED is blinking, but green LED’s are

not, replace LID module, (memory failure). Check light bulb if backlit model.

‘‘Communications Failure’’ Highlighted Message At

Bottom of LID Screen

LID is not properly addressed to the PSIO. Make sure that, on ATTACH TO

NETWORK DEVICE screen,.

LOCAL DEVICE

is set to read the PSIO ad-

dress. CheckLEDs onPSIO. Isred LED operatingproperly?Are greenLEDs

blinking? See Control Module troubleshooting section.

Control Test Disabled Press the Stop pushbutton. The PIC must be in the OFF mode for the con-

trol test feature to operate. Clear all alarms. Check line voltage percent on

STATUS01 screen. The percent must be within 90% to 110%. Check volt-

age input to SMM; calibrate starter voltage potentiometer for accuracy.

Vanes Will Not Open in Control Test Low pressure alarm is active. Put chiller into PUMPDOWN mode or equal-

ize pressure. Check guide vane actuator wiring.

Oil Pump Does Not Run Check oil pump voltage supply. Cooler vessel pressure under vacuum.

Pressurize vessel. Check temperature overload cutout switch.

LID Default Screen Does Not Update This is normal operation when an alarm is present. The screen freezes the

momentthe alarmis activatedtoaid introubleshooting.The STATUS01screen

provides current information.

Chiller Does Not Stop When the STOP Button is Pressed The STOP button wiring connector on the LID module is not properly con-

nected or the chiller is in soft stop mode and the guide vanes are

closing.

LID Screen Dark Light bulb burned out. Replace as needed.

92