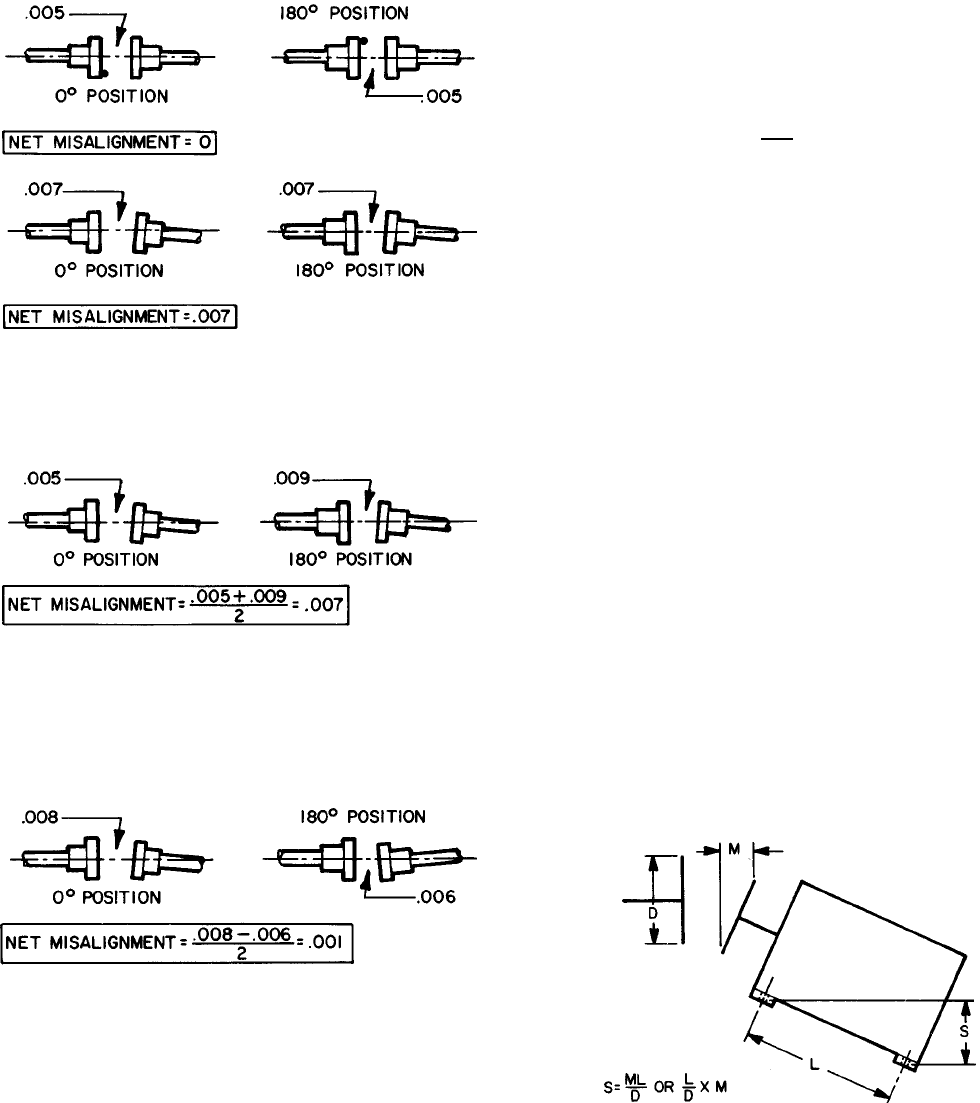

If the larger opening remains the same but changes from

side to side, the shafts are in perfect alignment. The change

in opening is due entirely to coupling runout, as above, or to

a burr or other damage to the coupling face.

If the larger opening remains the same, and remains

on the same side, the amount is entirely shaft (net)

misalignment.

If the larger opening remains on the same side but changes

amount, misalignment and runout are present. Add the two

amounts and then divide by two to get the actual or net

misalignment.

If the larger opening changes amount and also changes

from side to side, subtract the smaller amount from the larger

and divide by two to obtain the net misalignment.

Adjustment — Having obtained the net misalignment, the

amount by which the equipment must be moved can now be

calculated.

To determine:

S — amount of movement (in plan) or the thickness of

shim (in elevation) required.

Obtain:

D — coupling face diameter in inches (or indicator but-

ton circle)

L — distance between front and rear holddown bolts

(inches)

M — net misalignment in inches

And:

Divide L, the bolt distance, by D, the coupling diameter.

Multiply the result by M, the net misalignment.

L

S= × M

D

Example: Face diameter 5 in. (D). Distance between front

and rear holddown bolts 30 in. (L). Net misalign-

ment in elevation .012 in. (M).

30 divided by 5 is 6

6 multiplied by .012 is .072 in.

S = .072 in.

If the larger opening between coupling faces is at the top,

place .072 in. of shim under each rear foot or remove

.072 in. from the front footings to bring the couplings into

angular alignment in elevation.

Tighten the holddown bolts and recheck the net

misalignment.

The height of the shaft above the footings and the dis-

tance the shaft extends beyond the equipment will not affect

the calculations.

Determine the angular adjustment in plan by the same method

of calculation. At this point, however, the procedure should

include a correction for the change in coupling gap which

always occurs in adjusting angular alignment (Fig. 40). By

selecting the proper pivot point (see Fig. 41), the coupling

gap can be kept at the dimension specified in the job data.

1. Pivot on the front bolt at the closed side of the couplings

to shorten the gap; pivot on the front bolt at the open side

to lengthen it. It may sometimes be advantageous to pivot

half the required amount on one front footing and half on

the other.

2. Place a dial indicator against the rear foot as indicated in

Fig. 41.

3. Place a screw jack on the other rear foot to move the equip-

ment towards the indicator.

S—Thickness of Shim Required

L—Distance Between Front and

Rear Holddown Bolt in Inches

D—Diameter of Coupling in Inches

M—Net Misalignment in Inches

Fig. 40 — Alignment Formula

73