INDEX

Abbreviations, 5

Access the Service Screen, To (Service Operation), 42

Accidental Start-Up, To Prevent, 61

Accuracy, Check Sensor (Checking

Temperature Sensors), 84

Adding Refrigerant, 67

Adjusting the Refrigerant Charge, 67

After Extended Shutdown, 63

After Limited Shutdown, 63

After Power Failure,

Auto. Restart (Lead/Lag Control), 40

Auto. Restart (Controls), 36

Alarm Contacts, Spare, 36

Alarms and Alerts, 16

Alerts, Alarms and, 16

Algorithm, Surge Prevention, 37

Alignment,

Chiller, 71

Disc Coupling, and Installation, 59

Final (Chiller Alignment), 74

Near Final (Chiller Alignment), 71

Preliminary (Chiller Alignment), 71

Alignment Check,

Hot (Chiller Alignment), 74

Hot, 61

Alignment Methods (Chiller Alignment), 71

Altitude Locations, High, 57

Analog Signal (Controls), 11

Attach to Network Device Control, 41

Attaching to Other CCN Modules

(Attach to Network Device Control), 41

Auto. Restart After Power Failure (Controls), 36

Auto. Restart After Power Failure (Lead/Lag Control), 40

Automated Control Test, Perform an, 56

Automatic Soft Stop Amps Threshold, 44

Auxiliary Compressor Oil Pump Control, 33

Auxiliary Devices, Motor, 46

Auxiliary Equipment (Instruct the Operator), 62

Auxiliary Gear Oil Pump Control, 33

Balancing, Load (Lead/Lag Control), 40

Bearing Maintenance, Compressor, 82

Before Initial Start-Up, 45

Calibrate Motor Current Demand Setting, 61

Calibration, Oil Differential Pressure/Power Supply

Module (Checking Pressure Transducers), 85

Capacity Control, 32

Capacity Override, 35

Carrier Comfort Network Interface (CCN), 53

CCN Modules, Attaching to Other (Attach to

Network Device Control), 41

Change LID Configuration If Necessary, 55

Change Point Status, To View or, 17

Change Set Points, To View and, 22

Change Time Schedule Operation, To View or, 18

Changing the Oil Filters, 76

Charge, Compressor Oil, 54

Charge Refrigerant into Chiller, 57

Check,

Hot Alignment (Chiller Alignment), 74

Hot Alignment, 61

Resistance (Checking Temperature Sensors), 84

Check Chiller Operating Condition, 61

Check Chiller Tightness, 46

Check Insulation Resistance (Inspect Wiring), 50

Check Motor Rotation, 58

Check Oil Pressure and Compressor Stop, 61

Check Operator Knowledge, 62

Check Optional Pumpout Compressor Water Piping, 50

Check Pressure Transducers, 83

Check Pumpout System Controls and Optional

Pumpout Compressor, 56

Check Relief Devices, 50

Check Safety and Operating Controls Monthly, 76

Check Sensor Accuracy (Checking Temperature Sensors), 84

Check Starter, 53

Check the Compressor Oil Heater, Power Up

the Controls and, 54

Check the Lubrication System, 76

Check the Running System, 62

Check Voltage Supply, 56

Checking Guide Vane Linkage, 68

Checking Pressure Transducers, 84

Checking Temperature Sensors (Troubleshooting Guide), 84

Checking the Display Messages, 84

Checklist for 17EX Externally Geared Centrifugal

Liquid Chiller, Initial Start-Up, CL-1 to CL-12

Checkout Procedure, Control Algorithms, 85

Chilled Water Control, Entering, 32

Chilled Water Recycle Mode, 44

Chiller Alignment, 71

Chiller Communication Wiring (Lead/Lag Control), 38

Chiller Control Configuration, Set Up, 54

Chiller Cycles (Instruct the Operator), 62

Chiller Dehydration, 49

Chiller Familiarization, 17EX, 5

Chiller Identification Label, 5

Chiller Operating Condition, Check, 61

Chiller Parts, Ordering Replacement, 83

Chiller Tightness, Check, 46

Chiller Timers, 32

Chiller, Leak Test the, 46

Cleanliness (Motor Maintenance), 79

Cold Weather Operation, 63

Common Point Sensor Installation (Lead/Lag Control), 38

Communication Wiring, Chiller (Lead/Lag Control), 38

Components,

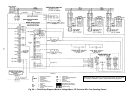

PIC System, 12

System, 5

Compressor, 5

Compressor Assembly (Instruct the Operator), 62

Compressor Bearing Maintenance, 82

Compressor Lubrication Cycle, 8

Compressor Lubrication System (Instruct the Operator), 62

Compressor Oil (Oil Changes), 77

Compressor Oil Charge, 54

Compressor Oil Cooling, 8

Compressor Oil Filter (Changing the Oil Filters), 76

Compressor Oil Pump Contactor (2C) and Gear

Oil Pump Contactor (5C), 16

Compressor Oil Pump Control, Auxiliary, 33

Compressor Stop, Check Oil Pressure and, 61

Compressor, Operating the Optional Pumpout, 63

Condenser, 5

Condenser (Inspect the Heat Exchanger Tubes), 82

Condenser Freeze Prevention, 36

Condenser Pump Control, 36

Configuration,

Change LID, If Necessary, 55

Modify Equipment, If Necessary, 56

Set Up Chiller Control, 54

Configurations, Input Service, 54

Contact Seal Maintenance, 68

Contactor (IC), Oil Heater, 16

Contactors, Compressor Oil Pump (2C) and

Gear Oil Pump (5C), 16

Contacts, Spare Alarm, 36

115