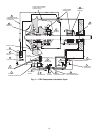

PIC System Components — The Product Integrated

Control (PIC) is the control system on the chiller. See

Table 1. The PIC controls the operation of the chiller by moni-

toring all operating conditions. The PIC can diagnose a prob-

lem and let the operator know what the problem is and what

to check. It promptly positions the guide vanes to maintain

leaving chilled water temperature. It can interface with aux-

iliary equipment such as pumps and cooling tower fans to

turn them on only when required. It continually checks all

safeties to prevent any unsafe operating condition. It also

regulates the oil heater while the compressor is off and the

hot gas bypass valve, if installed. See Fig. 6-10 for the lo-

cations of sensors, transducers, and other devices controlled

and/or monitored by the PIC system.

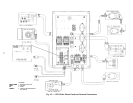

The PIC can be interfaced with the Carrier Comfort

Network (CCN) if desired. It can communicate with other

PIC-equipped chillers and other CCN devices.

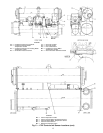

The PIC consists of 4 modules housed inside one of 3 lo-

cations: the control center, the power panel, or the starter

cabinet. The component names and the control voltage of

each location are listed below (also see Table 1):

• control center

— all extra low-voltage wiring (24 v or less)

• power panel

— 115 v control voltage

— up to 600 v for oil pump power

• starter cabinet

— chiller power wiring (per job requirement)

Table 1 — Major PIC Components and

Panel Locations*

PIC COMPONENT

PANEL

LOCATION

Processor Sensor Input/Output Module

(PSIO)

Control Center

Starter Management Module (SMM) Starter Cabinet

Local Interface Device (LID) Control Center

6-Pack Relay Board Control Center

8-Input Modules (Optional) Control Center

4-In/2-Out Module Power Panel

Oil Differential Pressure/Power Supply

Module

Control Center

Oil Heater Contactor (1C) Power Panel

Compressor Oil Pump Contactor (2C) Power Panel

Gear Oil Pump Contactor (5C) Power Panel

Hot Gas Bypass Relay (3C) (Optional) Power Panel

Control Transformers (T1-T4) Power Panel

Control and Oil Heater Voltage Selector (S1) Power Panel

Temperature Sensors See Fig. 7

Pressure Transducers See Fig. 7

*See Fig. 6-10.

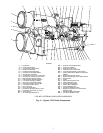

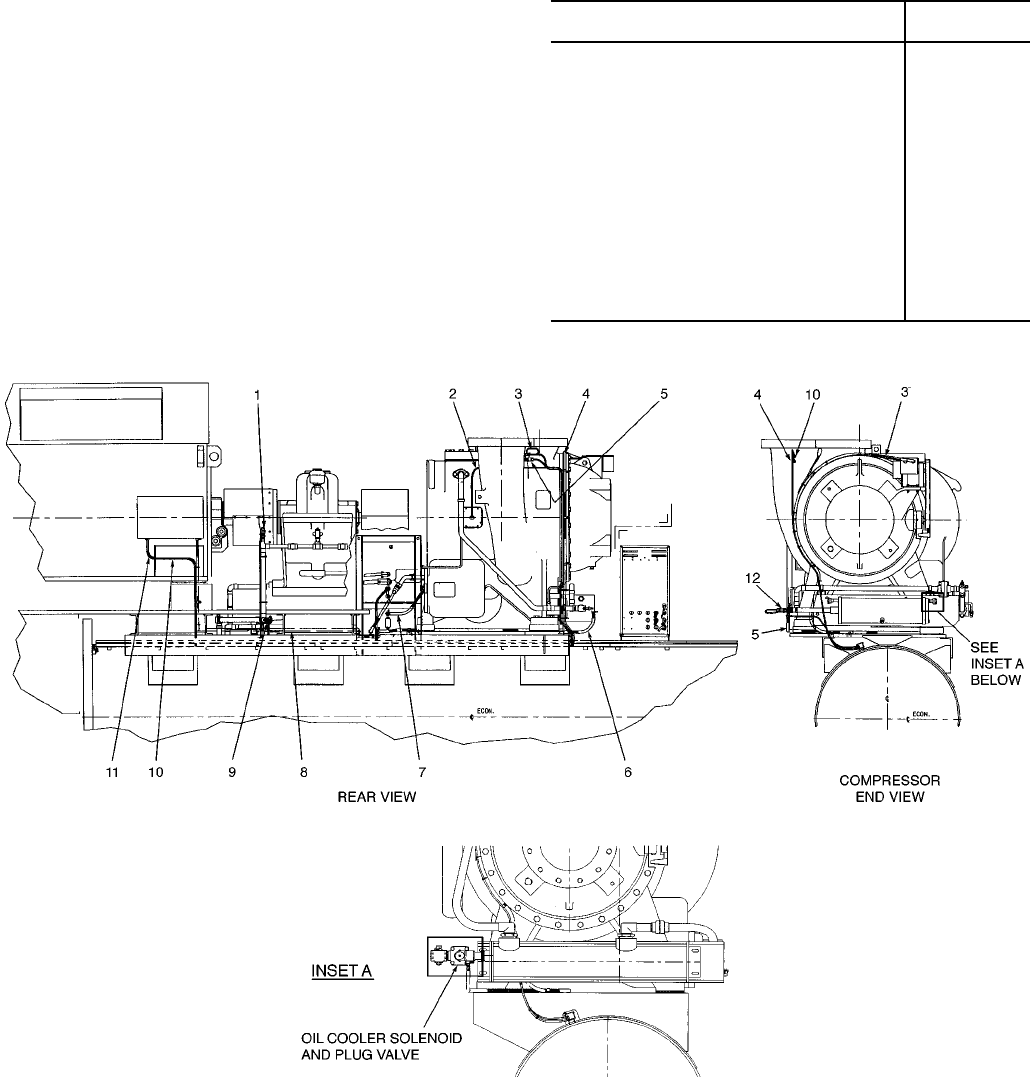

LEGEND

1—Gear Oil Pressure Sensor

2—Thrust Bearing Temperature and

Impeller Displacement Cable

3—Discharge Temperature Sensor

4—Guide Vane Conduit and Cable

5—High Pressure Cutout Switch

6—Compressor Oil Cooler

Solenoid Conduit

7—Oil Heater Conduit

8—Motor Space Heater Conduit

9—Gear Oil Temperature Sensor

10 — Motor High Temperature Switch Cable

Fig. 6 — 17EX Controls and Sensor Locations

REAR

11 — Motor Water Cooling Leak Detector

Cable (TEWAC Motor Only)

12 — Discharge Oil Pressure Sensor

TEWAC — Totally Enclosed Water-to-Air Cooled

12