INTRODUCTION

Before initial start-up of the 17EX unit, those involved in

the start-up, operation, and maintenance should be thor-

oughly familiar with these instructions and other necessary

job data. This book is outlined so that you may become fa-

miliar with the control system before performing start-up pro-

cedures. Procedures in this manual are arranged in the se-

quence required for proper chiller start-up and

operation.

This unit uses a microprocessor controlled system. Do

not short or jumper between terminations on circuit boards

or modules; control or board failure may result.

Be aware of electrostatic discharge (static electricity) when

handling or making contact with circuit boards or mod-

ule connections. Always touch a chassis (grounded) part

to dissipate body electrostatic charge before working in-

side the control center.

Use extreme care when handling tools near boards and

when connecting or disconnecting terminal plugs.

Circuit boards can easily be damaged. Always hold boards

by the edges and avoid touching components and

connections.

This equipment uses, and can radiate, radio frequency

energy. If not installed and used in accordance with

the instruction manual, it may cause interference to

radio communications. It has been tested and found to

comply with the limits for a Class A computing device

pursuant to Subpart J of Part 15 of FCC Rules, which

are designed to provide reasonable protection against such

interference when operated in a commercial environ-

ment. Operation of this equipment in a residential area

is likely to cause interference, in which case the user, at

his own expense, will be required to take whatever mea-

sures may be required to correct the interference.

Always store and transport replacement or defective boards

in anti-static shipping bag.

ABBREVIATIONS

Frequently used abbreviations in this manual include:

CCN — Carrier Comfort Network

CCW — Counterclockwise

CHW — Chilled Water

CHWR — Chilled Water Return

CHWS — Chilled Water Supply

CW — Clockwise

ECW — Entering Chilled Water

ECDW — Entering Condenser Water

EMS — Energy Management System

HGBP — Hot Gas Bypass

I/O — Input/Output

LCD — Liquid Crystal Display

LCDW — Leaving Condenser Water

LCW — Leaving Chilled Water

LED — Light-Emitting Diode

LID — Local Interface Device

OLTA — Overload Trip Amps

PIC — Product Integrated Control

PSIO — Processor Sensor Input/

Output Module

RLA — Rated Load Amps

SCR — Silicon Control Rectifier

SMM — Starter Management Module

TXV — Thermostatic Expansion Valve

17EX CHILLER FAMILIARIZATION

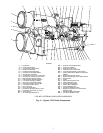

Chiller Identification Label (Fig. 1) —

The iden-

tification label is located on the right side of the chiller con-

trol center panel. The label contains information on model

number, refrigerant charge, rated voltage, etc.

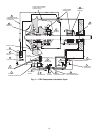

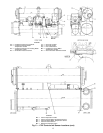

System Components (Fig. 2) — The components

include the cooler and condenser heat exchangers in sepa-

rate vessels, compressor, compressor and gear lubrication pack-

ages, control center, speed increaser economizer/storage vessel,

motor, and starter. The compressor drive consists of an ex-

ternal gear (speed increaser) and an electric motor. All con-

nections from pressure vessels have external threads to en-

able each component to be pressure tested with a threaded

pipe cap during factory assembly.

Cooler — This vessel (also known as the evaporator) is

located underneath the condenser, next to the economizer/

storage vessel. The cooler is maintained at lower tempera-

ture and pressure so that evaporating refrigerant can remove

heat from water flowing through its internal tubes.

Condenser — The condenser operates at a higher tem-

perature and pressure than the cooler and has water flowing

through its internal tubes in order to remove heat from the

refrigerant.

Compressor — This component maintains system tem-

perature and pressure differences and moves the heat-

carrying refrigerant from the cooler to the condenser.

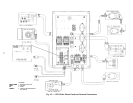

Control Center — The control center is the user inter-

face for controlling the chiller and regulates the chiller ca-

pacity as required to maintain proper leaving chilled

water temperature. The control center:

• registers cooler, condenser, and lubricating system

pressures

• shows chiller operating and alarm shutdown conditions

• records the total chiller operating hours and how many hours

the chiller has been running

• sequences chiller start, stop, and recycle under micro-

processor control

• provides access to other CCN (Carrier Comfort Network)

devices

Motor Starter (Purchased Separately) — The starter

allows the proper start and disconnect of electrical energy

for the compressor-motor, oil pump, oil heater, and control

panels.

Economizer/Storage Vessel — During normal op-

eration, this vessel functions as an economizer, returning flash

gas to the second stage of the compressor and increasing the

efficiency of the refrigeration cycle. During periods of shut-

down and service, the economizer/storage vessel can serve

as a storage tank for the refrigerant.

REFRIGERATION CYCLE (Fig. 3)

The 17EX chiller can be used to chill either water or brine.

The data in this book applies to either application. Appli-

cations using corrosive brines may require using special tubes,

tubesheet, and waterbox materials which are special order

items.

5