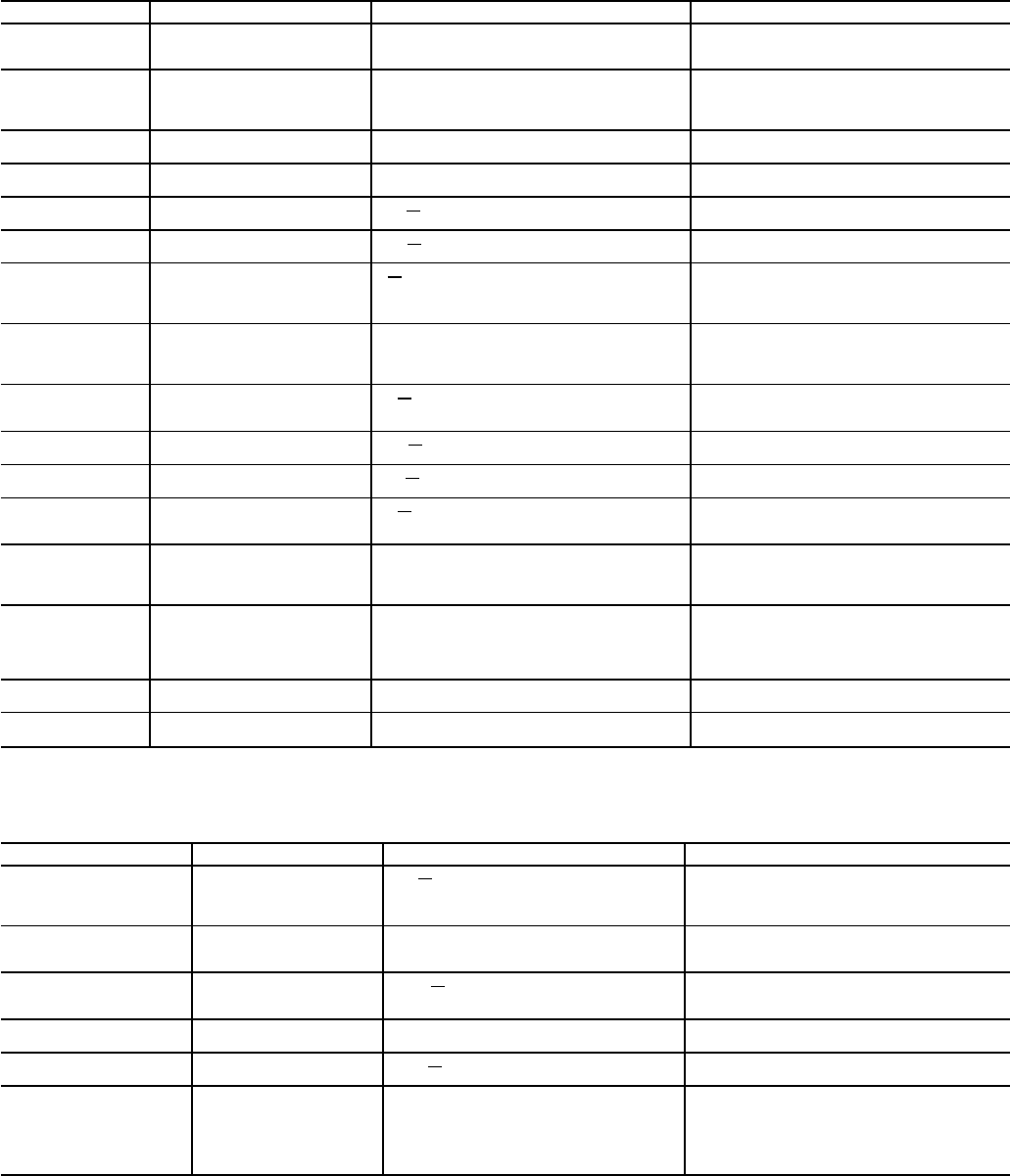

Table 12 — LID Primary and Secondary Messages and Custom Alarm/Alert Messages

with Troubleshooting Guides (cont)

G. START-UP FAILURES: This is an alarm condition. A manual reset is required to clear.

PRIMARY MESSAGE SECONDARY MESSAGE ALARM MESSAGE/PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

FAILURE TO START LOW OIL PRESSURE OILPD [VALUE] exceeded limit of [LIMIT]*. Check

oil pump system.

Check for closed oil supply valves. Check oil filter.

Check for low oil temperature. Check transducer

accuracy.

FAILURE TO START OIL PRESS SENSOR FAULT OILPD [VALUE] exceeded limit of [LIMIT]*. Check

oil pressure sensor.

Check forexcessive refrigerant in oilsump. Run oil

pump manually for 5 minutes. Check calibration of

oilpressuredifferentialamplifiermodules.Checkwir-

ing. Replace transducers if necessary.

FAILURE TO START LOW CHILLED WATER FLOW EVFL Evap Flow Fault: Check water pump/flow

switch.

Check wiring to flow switch. Check through CON-

TROL TEST for proper switch operation.

FAILURE TO START LOW CONDENSER

WATER FLOW

CDFL Cond. Flow Fault: Check water pump/flow

switch.

Check wiring to flow switch. Check through CON-

TROL TEST for proper switch operation.

FAILURE TO START STARTER FAULT STR FLT Starter Fault: Check Starter for Fault

Source.

Astarterprotectivedevicehasfaulted.Checkstarter

for ground fault, voltage trip, temperature trip, etc.

FAILURE TO START STARTER OVERLOAD TRIP STR FLT Starter Overload Trip: Check amps

calibration/reset overload.

Reset overloads, check ICRrelay before restarting

chiller.

FAILURE TO START LINE VOLTAGE DROPOUT V P Single-Cycle Dropout Detected: Check volt-

age supply.

Check voltage supply. Check transformers for sup-

ply.Checkwithutilityifvoltagesupplyiserratic.Moni-

tor must be installed to confirm consistent, single-

cycle dropouts. Check low oil pressure switch.

FAILURE TO START HIGH CONDENSER

PRESSURE

High Condenser Pressure [LIMIT]:* Check switch

2C aux, and water temperature/flow.

Check for proper design condenser flow and tem-

perature.Checkcondenserapproach.Check2Caux-

iliary contactson oilsump starter. Check highpres-

sure switch.

FAILURE TO START EXCESS ACCELERATION

TIME

CA PExcessAcceleration:Checkguidevaneclo-

sure at start-up.

Checkthatguidevanesareclosedatstart-up. Check

starter for proper operation. Reduce unit pressure

if possible.

FAILURE TO START STARTER TRANSITION

FAULT

RUN AUX Starter Transition Fault: Check 1CR/

1M/Interlock mechanism.

Check starter for proper operation.

Run contact failed to close.

FAILURE TO START 1CR AUX CONTACT FAULT 1CR AUX Starter Contact Fault: Check 1CR/1M

aux. contacts.

Check starter for proper operation.

Start contact failed to close.

FAILURE TO START MOTOR AMPS NOT SENSED CA PMotorAmps NotSensed:Check motorload

signal.

Checkforproper motorampssignaltoSMM.Check

wiringfromSMMto currenttransformer.Checkmain

motor circuit breaker for trip.

FAILURE TO START CHECK REFRIGERANT TYPE Current Refrigerant PropertiesAbnormal — Check

Selection of refrigerant type.

Pressures at transducers indicate another refriger-

anttypein controltest.Makesure toaccesstheAT-

TACH TO NETWORK DEVICE screen after speci-

fying HFC-134a refrigerant type.

FAILURE TO START LOW OIL PRESSURE LowOilPressure[LIMIT]:*Checkoilpressureswitch/

pump and 2C aux.

Theoilpressure differentialswitchisopen whenthe

compressortriedtostart.Checktheswitchfor proper

operation.Also, checktheoilpumpinterlock(2Caux)

in the power panel and the high condenser pres-

sure switch.

FAILURE TO START LOW GEAR OIL PRESSURE GEAROILP [VALUE] exceeded limit of [LIMIT].*

Check gear oil pump/filter.

Check for closed oil supply valves. Check oil filter.

Check transducer accuracy.

FAILURE TO START GEAR OIL PRESSURE SENSOR GearOilPressureTransducerOutofRange[VALUE]. Check calibration of transducer. Replace if

necessary.

*[LIMIT]is shownon theLID asthetemperature, pressure,voltage, etc.,setpoint predefinedor selectedby theoperatoras anoverride, alert,oralarm condition.[VALUE]

is the actual pressure, temperature, voltage, etc., at which the control tripped.

H. COMPRESSOR JUMPSTART AND REFRIGERANT PROTECTION

PRIMARY MESSAGE SECONDARY MESSAGE ALARM MESSAGE/PRIMARY CAUSE ADDITIONAL CAUSE/REMEDY

UNAUTHORIZED

OPERATION

UNIT SHOULD BE

STOPPED

CA P Emergency: Compressor

running without control authorization.

Compressor is running with more than 10% RLA

and control is trying to shut it down. Turn power

offtocompressorifunabletostop.Determinecause

before re-powering.

POTENTIAL FREEZE-UP EVAP PRESS/TEMP

TOO LOW

ERT Emergency: Freeze-up

prevention.

Determine cause. If pumping refrigerant out of

chiller, stop operation and go over pumpout

procedures.

FAILURE TO STOP DISCONNECT POWER RUN AUX Emergency: DISCONNECT

POWER.

Starterrun andstartcontactsare energizedwhile

control tried to shut down. Disconnect power to

starter.

LOSS OF

COMMUNICATION

WITH STARTER Loss of Communication with Starter: Check

chiller.

CheckwiringfromPSIOtoSMM.CheckSMMmod-

ule troubleshooting procedures.

STARTER CONTACT

FAULT

ABNORMAL 1CR OR

RUN AUX

1CR AUX Starter Contact Fault: Check

1CR/1M aux. contacts.

Starterrunandstartcontactsenergizedwhilechiller

was off. Disconnect power.

POTENTIAL FREEZE UP COND PRESS/TEMP

TOO LOW

CRT [VALUE] exceeded limit of [LIMIT]*

Emergency: Freeze-up prevention.

The condenser pressure transducer is reading a

pressure that could freeze the water in the con-

densertubes.Checkforcondenserrefrigerantleaks,

bad transducers,or transferredrefrigerant. Place

the unit in PUMPDOWN mode to eliminate the

alarm if vessel is evacuated.

*[LIMIT]is shownon theLID asthetemperature, pressure,voltage, etc.,setpoint predefinedor selectedby theoperatoras anoverride, alert,oralarm condition.[VALUE]

is the actual pressure, temperature, voltage, etc., at which the control tripped.

88