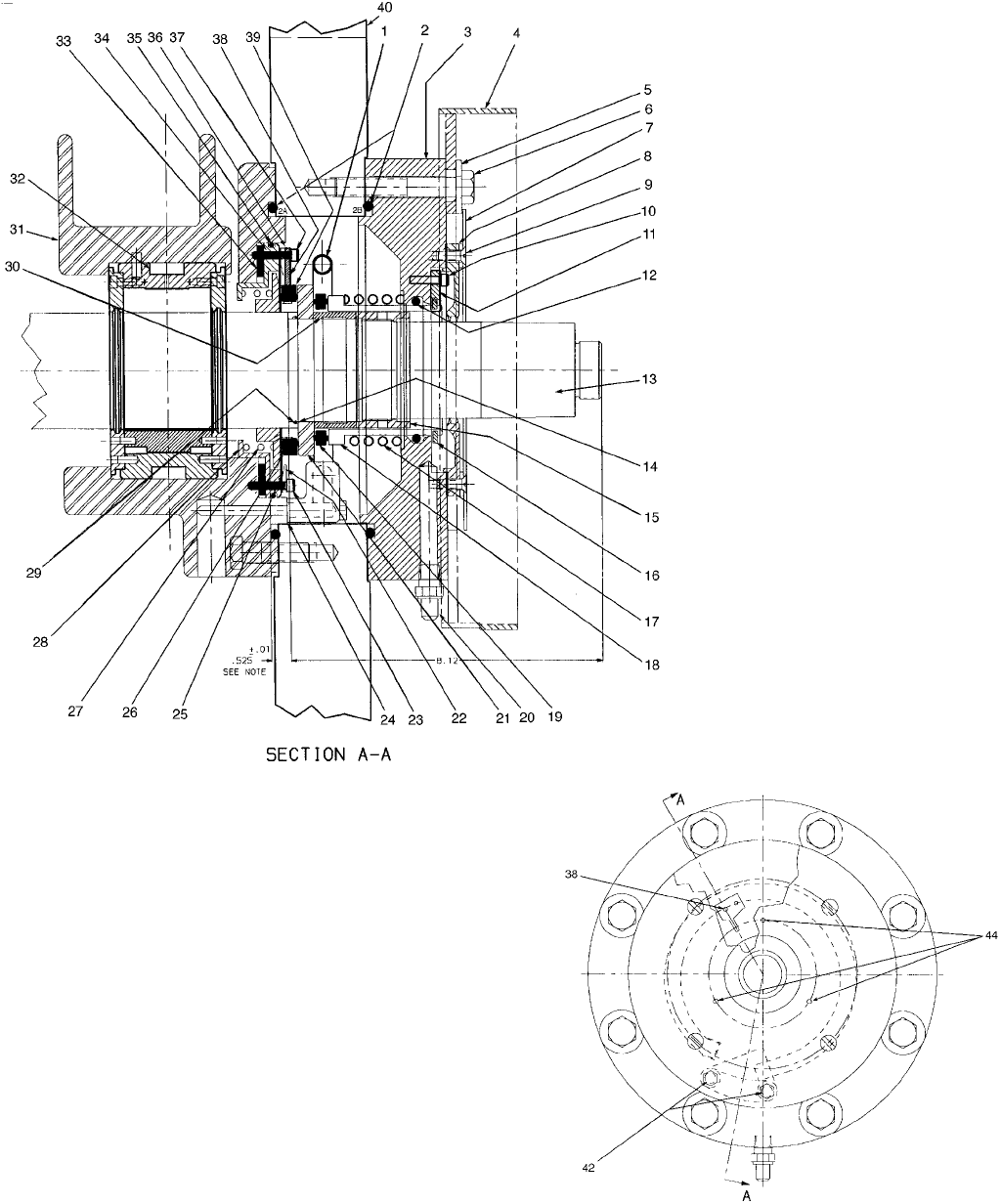

LEGEND

1—Lubricating Tube

2A — O-Ring

2B — O-Ring

3—Seal Housing

4—Coupling Guard Mounting Ring

5—Plain

1

⁄

2

-in. Washer (8 Required)

6—Hex Head Bolt,

1

⁄

2

-13×4lg(8Required)

7—Windage Baffle

8—Shaft End Labyrinth

9—Screw

1

⁄

4

-20×

3

⁄

4

lg (4 Required)

10 — Screw, 10-24 ×

1

⁄

2

lg

11 — Key, Contact Sleeve

12 — O-Ring

13 — Compressor Shaft

14 — O-Ring

15 — Lock Nut

16 — Snap Ring (Service tool only; must be removed for operation)

17 — Spring Contact Sleeve

18 — Contact Sleeve

19 — Outer Carbon Ring

20 — Coupling (Connection to atmospheric oil chamber)

21 — Rotating Contact Ring

22 — Diaphragm Retainer

23 — Inner Seal Retaining Screw, 10-24×1lg(14Required)

24 — Gasket

25 — Diaphragm

26 — Inner Carbon Ring

27 — Inner Seal Spring

28 — Inner Seal Retainer

29 — Seal Gland Sleeve

30 — Spacer

31 — Journal Bearing Housing

32 — Journal Bearing

33 — Inner Seal Shim

34 — Inner Carbon Guide Ring

35 — O-Ring

36 — Inner Carbon Key

37 — Screw, 10-24 × 1

1

⁄

4

lg (2 Required)

38 — Retaining Ring

39 — Seal Shoulder

40 — Compressor End Wall

41 — Thread Cut Screw, 8-32 ×

1

⁄

4

lg (3 Required)

42 — Screw,

5

⁄

16

-18×1

3

⁄

4

lg (2 Required)

Fig. 36 — Contact Seal

NOTE: Adjust shims (Item 33) to main-

tain .525 ± .01 in. (13.3 ± .3 mm) dimen-

sionwithshaft thrusttowarddriveand check

carbon for +.06 minimum travel.

69