Teledyne API – Model T300/T300M CO Analyzer Theory of Operation

305

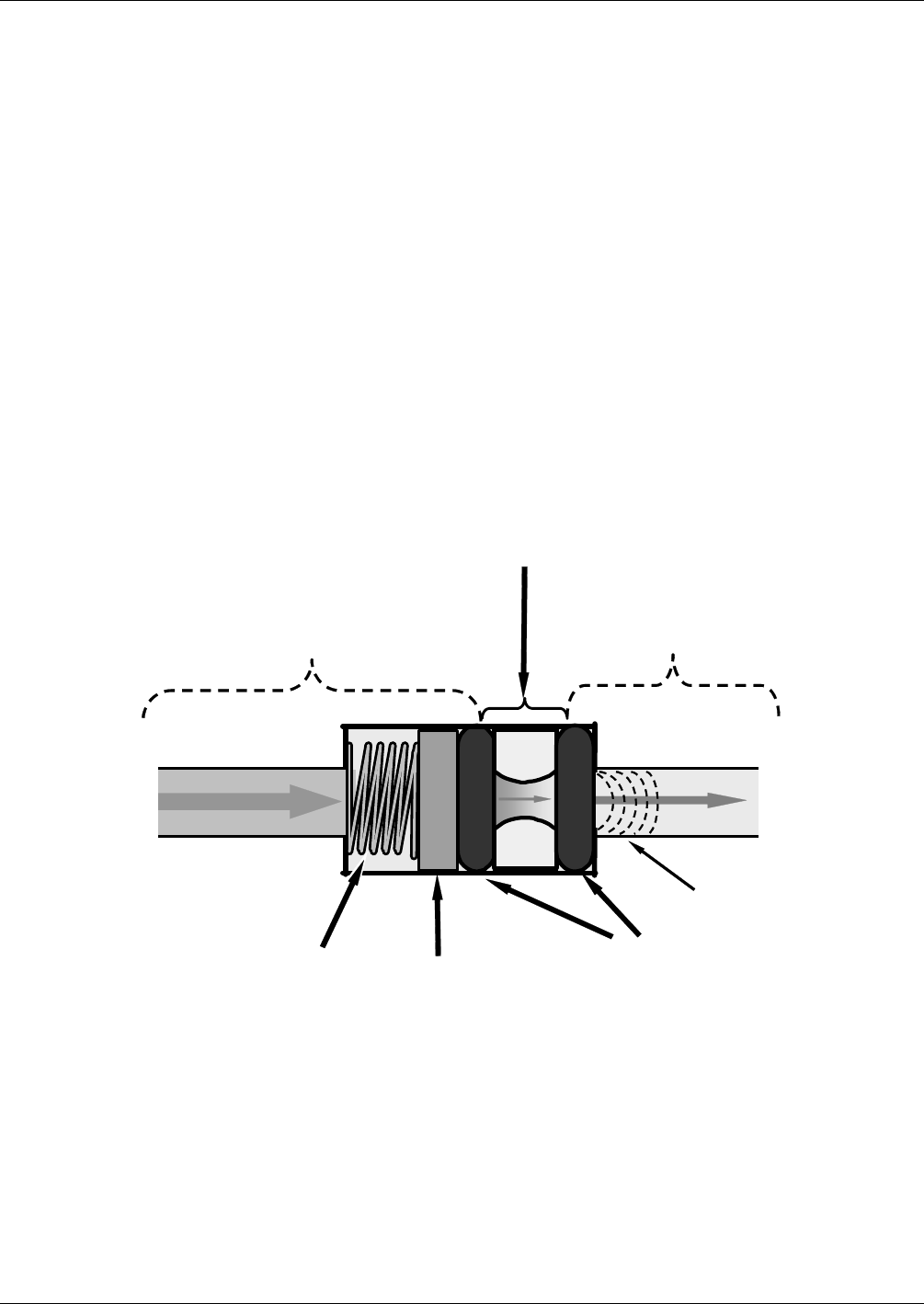

13.3.1.1. CRITICAL FLOW ORIFICE

The most important component of this flow control assembly is the critical flow orifice.

Critical flow orifices are a remarkably simple way to regulate stable gas flow rates.

They operate without moving parts by taking advantage of the laws of fluid dynamics.

By restricting the flow of gas though the orifice, a pressure differential is created. This

pressure differential combined with the action of the analyzer’s pump draws the gas

through the orifice.

As the pressure on the downstream side of the orifice (the pump side) continues to drop,

the speed that the gas flows through the orifice continues to rise. Once the ratio of

upstream pressure to downstream pressure is greater than 2:1, the velocity of the gas

through the orifice reaches the speed of sound. As long as that ratio stays at least 2:1,

the gas flow rate is unaffected by any fluctuations, surges, or changes in downstream

pressure because such variations only travel at the speed of sound themselves and are

therefore cancelled out by the sonic shockwave at the downstream exit of the critical

flow orifice.

SPRING

O-RINGS

FILTER

CRITICAL

FLOW

ORIFICE

A

REA OF

LOW

PRESSURE

AREA OF

HIGH

PRESSURE

Sonic

Shockwave

Figure 13-8: Flow Control Assembly & Critical Flow Orifice

The actual flow rate of gas through the orifice (volume of gas per unit of time), depends

on the size and shape of the aperture in the orifice. The larger the hole, the more the gas

molecules move at the speed of sound and pass through the orifice. Because the flow

rate of gas through the orifice is only related to the minimum 2:1 pressure differential

and not absolute pressure, the flow rate of the gas is also unaffected by degradations in

pump efficiency due to age.

The critical flow orifice used in the T300/T300M is designed to provide a flow rate of

800 cc/min.

06864B DCN6314