Teledyne API – Model T300/T300M CO Analyzer Communications Setup and Operation

165

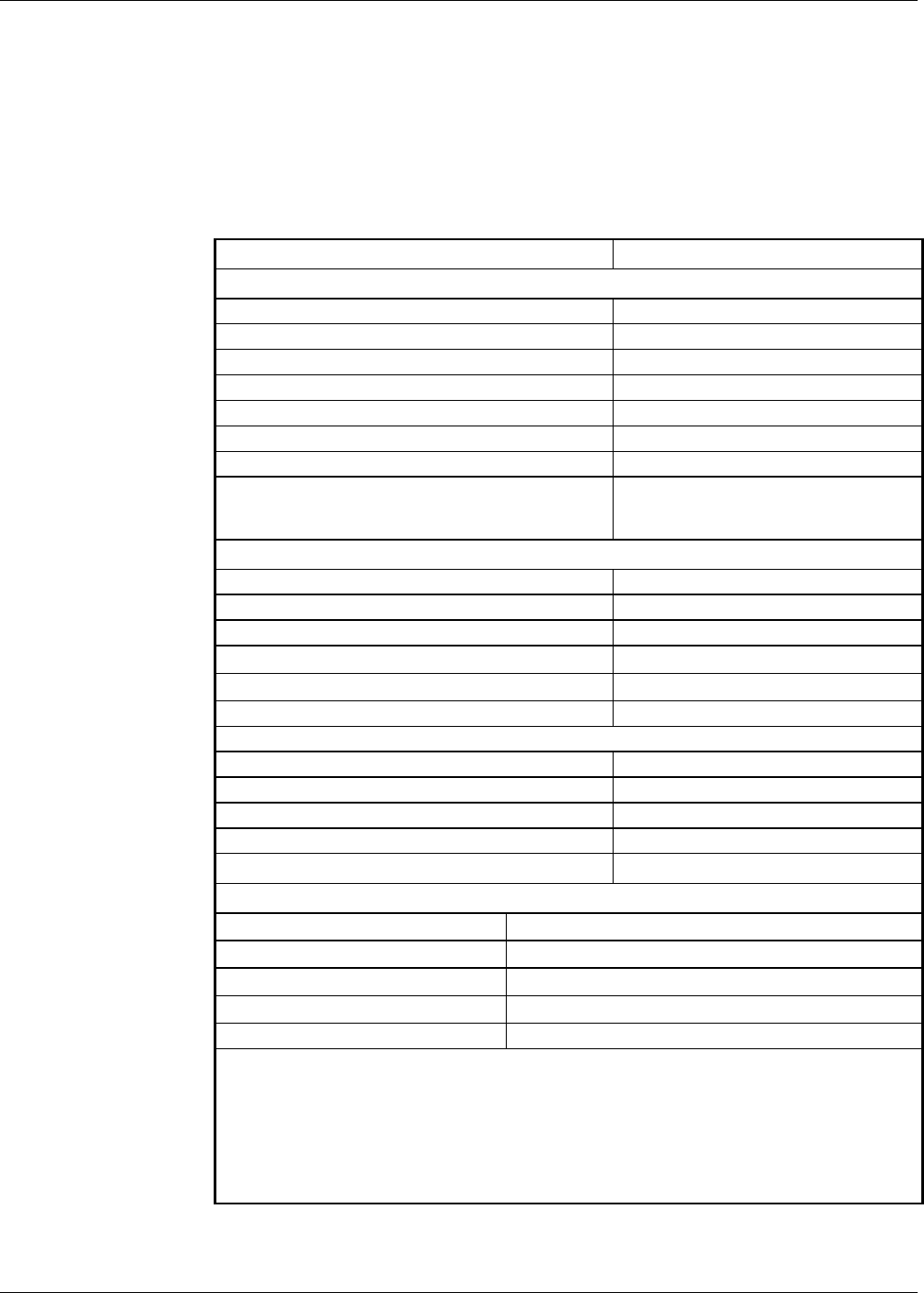

6.7.3.4. SETTING HESSEN PROTOCOL STATUS FLAGS

Teledyne API’s implementation of Hessen protocols includes a set of status bits that the

instrument includes in responses to inform the host computer of its condition. Each bit

can be assigned to one operational and warning message flag. The default settings for

these bit/flags are:

Table 6-6: Default Hessen Status Flag Assignments

STATUS FLAG NAME DEFAULT BIT ASSIGNMENT

WARNING FLAGS

SAMPLE FLOW WARNING 0001

BENCH TEMP WARNING 0002

SOURCE WARNING 0004

BOX TEMP WARNING 0008

WHEEL TEMP WARNING 0010

SAMPLE TEMP WARN 0020

SAMPLE PRESS WARN 0040

INVALID CONC

(The Instrument’s Front Panel Display Will Show The

Concentration As “Warnings”)

0080

OPERATIONAL FLAGS

1

Instrument OFF 0100

In MANUAL Calibration Mode 0200

In ZERO Calibration Mode

4

0400

In O

2

Calibration Mode (if O

2

sensor installed )

2,4

0400

In CO

2

Calibration Mode (if CO

2

sensor installed )

2,4

0400

In SPAN Calibration Mode 0800

UNITS OF MEASURE FLAGS

UGM 0000

MGM 2000

PPB 4000

PPM 6000

SPARE/UNUSED BITS

1000, 8000

UNASSIGNED FLAGS (0000)

AZERO WARN

2

DCPS WARNING

CANNOT DYN SPAN

2

REAR BOARD NOT DET

CANNOT DYN ZERO

3

SYNC WARNING

1

CONC ALARM 1

3

SYSTEM RESET

1

CONC ALARM 2

3

1

These status flags are standard for all instruments and should probably not be modified.

2

Only applicable if the optional internal span gas generator is installed.

3

Only applicable if the analyzer is equipped with an alarm options.

3

It is possible to assign more than one flag to the same Hessen status bit. This allows the grouping of

similar flags, such as all temperature warnings, under the same status bit.

Be careful not to assign conflicting flags to the same bit as each status bit will be triggered if any of the

assigned flags is active.

06864B DCN6314