Troubleshooting and Service Teledyne API – Model T300/T300M CO Analyzer

282

12.5.7.3. OPTO PICKUP ASSEMBLY

Operation of the opto pickup PCA (P/N 04088) can be verified with a voltmeter.

Measure the AC and DC voltage between digital ground on the relay board, or

touchscreen and TP2 and TP4 on the sync pickup PCA. For a working board, with the

GFC motor spinning, they should read 2.4 ±0.1 VAC and 2.5 ±0.15 VDC.

Further confirmation that the pickups and motor are operating properly can be obtained

by measuring the frequency at TP2 and TP4 using a frequency counter, a digital

voltmeter with a frequency counter, or an oscilloscope, per Table 12-9.

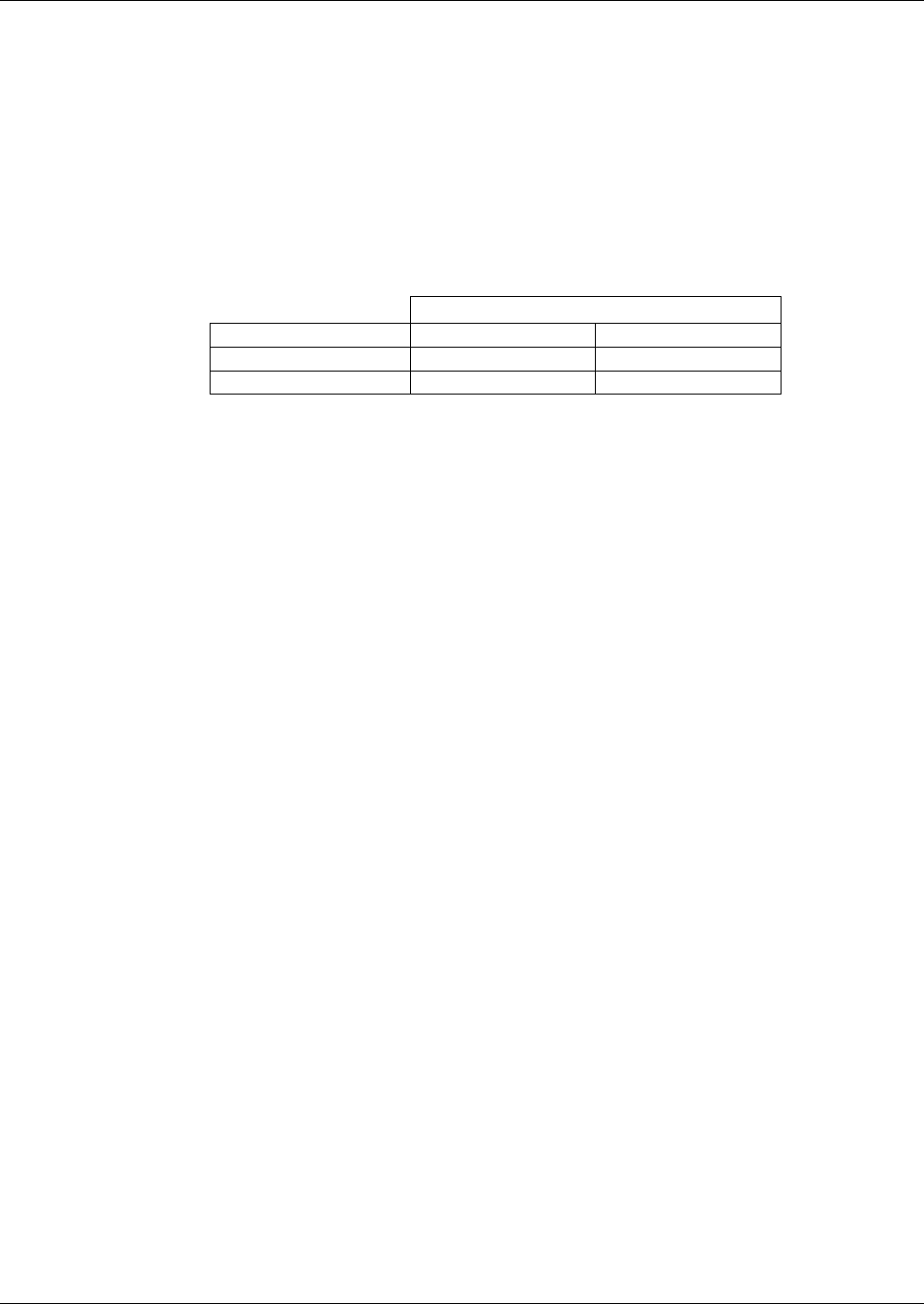

Table 12-9: Opto Pickup Board Nominal Output Frequencies

Nominal Measured Frequency

AC Mains Freq. TP2 TP4

50 Hz 25 300

60 Hz 30 360

12.5.7.4. GFC WHEEL DRIVE

If the D1 and D2 on the sync demodulator board are not flashing then:

1. Check for power to the motor by measuring between pins 1 and 3 on the connector

feeding the motor.

For instruments configured for 120 or 220-240VAC there should be

approximately 88 VAC for instruments configured for 100VAC, it should be the

voltage of the AC mains, approximately 100VAC.

2. Verify that the frequency select jumper, JP4, is properly set on the relay board.

For 50 Hz operation it should be installed.

For 60 Hz operation may either be missing or installed in a vertical orientation.

3. If there is power to the motor and the frequency select jumper is properly set then

the motor is likely bad.

See Section 12.6.2 for instructions on removing and replacing the GFC

ass

e

mbly that the motor is bolted to.

12.5.7.5. IR SOURCE

The IR source can be checked using the following procedure:

1. Disconnect the source and check its resistance when cold.

When new, the source should have a cold resistance of more than 1.5 Ohms

but less than 3.5 Ohms.

If not, then the source is bad.

2. With the source disconnected, energize the analyzer and wait for it to start

operating.

Measure the drive Voltage between pins 1 and 2 on the jack that the source is

normally connected to; it should be 11.5 ± 0.25 VDC.

If not, then the problem is with the wiring, the relay board, or the +12V power

supply.

3. If the drive voltage is correct in step 2, then remove the source from the heat sink

assembly (2 screws on top) and connect to its mating connector.

Observe the light being emitted from the source.

It should be centered at the bottom of the U-shaped element.

If there is either no emission or a badly centered emission, then the source is

bad.

06864B DCN6314