Teledyne API – Model T300/T300M CO Analyzer Troubleshooting and Service

257

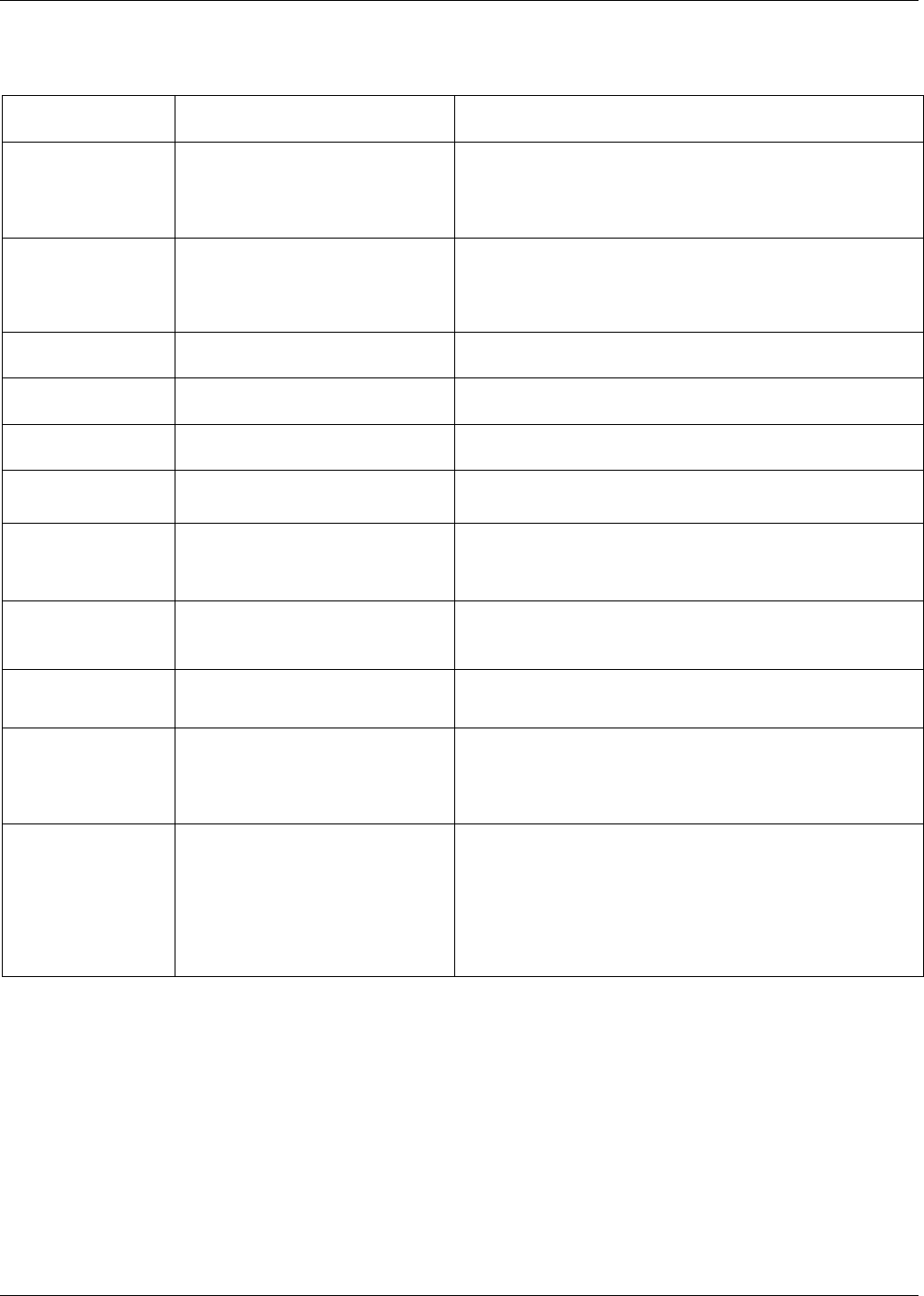

Table 12-1: Warning Messages - Indicated Failures

WARNING

MESSAGE

FAULT CONDITION POSSIBLE CAUSES

BENCH TEMP

WARNING

The optical bench temp is

controlled at 48 2

°

C.

Bad bench heater

Bad bench temperature sensor

Bad relay controlling the bench heater

Entire relay board is malfunctioning

I

2

C bus malfunction

BOX TEMP

WARNING

Box Temp is

< 5

°

C or > 48

°

C.

NOTE: Box temperature typically runs ~7

o

C warmer than ambient

temperature.

Poor/blocked ventilation to the analyzer.

Stopped exhaust-fan

Ambient temperature outside of specified range

CANNOT DYN

SPAN

Dynamic Span operation failed

Measured concentration value is too high or low.

Concentration slope value to high or too low

CANNOT DYN

ZERO

Dynamic Zero operation failed

Measured concentration value is too high.

Concentration offset value to high.

CONFIG

INITIALIZED

Configuration and Calibration data

reset to original Factory state.

Failed disk on module

User erased data

DATA INITIALIZED

Data Storage in DAS was erased

Failed disk on module

User cleared data

PHOTO TEMP

WARNING

PHT DRIVE is

>4800 mVDC

Failed IR photo-detector

Failed sync/demod board

IR photo-detector improperly attached to the sample chamber

Bench temp too high.

REAR BOARD NOT

DET

Motherboard not detected on power

up.

Warning only appears on serial I/O com port(s)

Front panel display will be frozen, blank or will not respond.

Massive failure of motherboard

RELAY BOARD

WARN

The CPU cannot communicate with

the Relay Board.

I

2

C bus failure

Failed relay board

Loose connectors/wiring

SAMPLE FLOW

WARN

Sample flow rate is < 500 cm

3

/min

or > 1000 cm

3

/min.

Failed sample pump

Blocked sample inlet/gas line

Dirty particulate filter

Leak downstream of critical flow orifice

Failed flow sensor/circuitry

SAMPLE PRES

WARN

Sample Pressure is <10 in-Hg or

> 35 in-Hg

Normally 29.92 in-Hg at sea level

decreasing at 1 in-Hg per 1000 ft of

altitude (with no flow – pump

disconnected).

If sample pressure is < 10 in-hg:

Blocked particulate filter

Blocked sample inlet/gas line

Failed pressure sensor/circuitry

If sample pressure is > 35 in-hg:

Pressurized sample gas. Install vent

Blocked vent line on pressurized sample/zero/span gas supply

Bad pressure sensor/circuitry

06864B DCN6314