Calibration Procedures Teledyne API – Model T300/T300M CO Analyzer

214

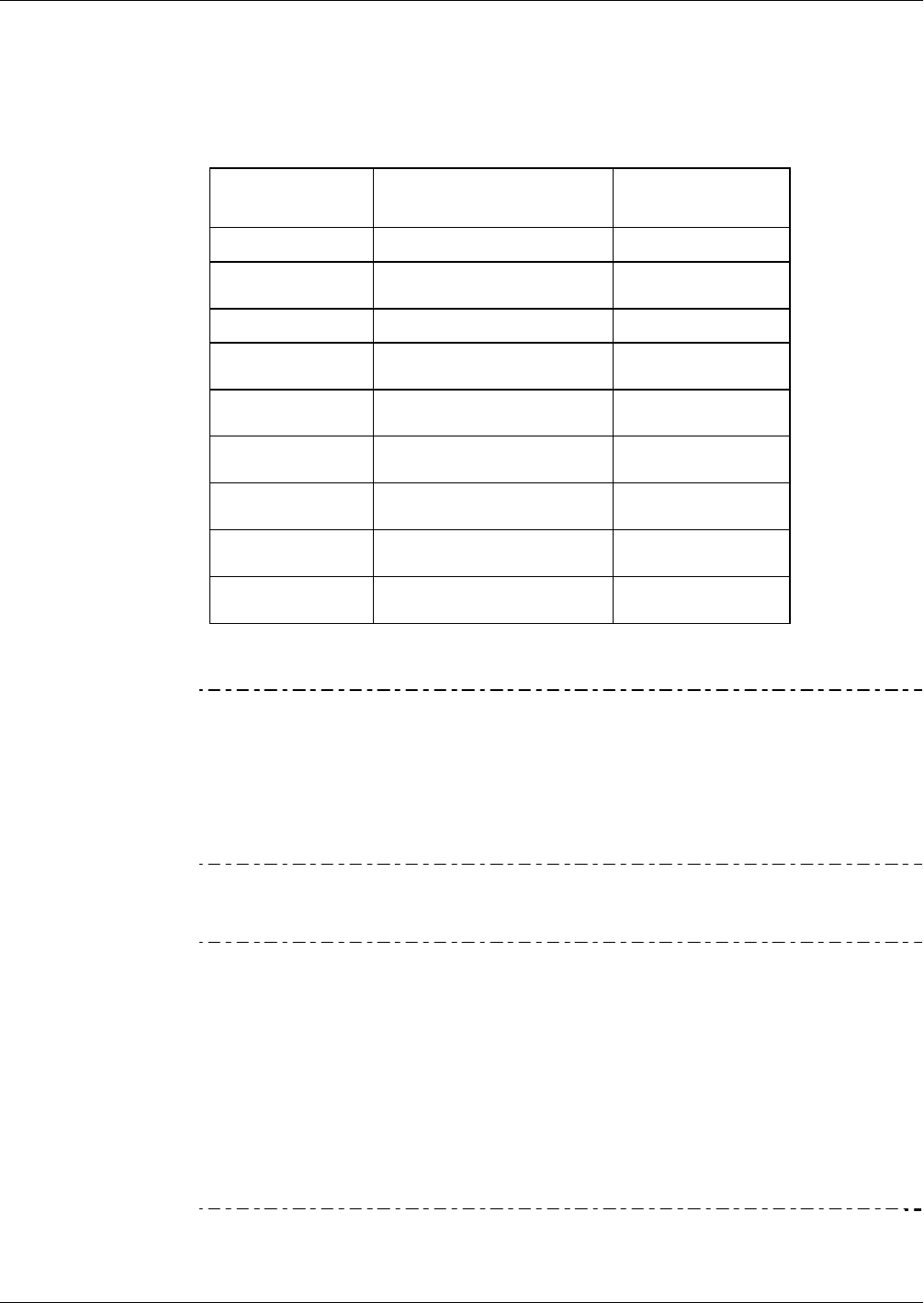

The following example sets sequence #2 to do a zero-span calibration every other day

starting at 2:15 PM on September 4, 2008, lasting 15 minutes, without calibration. This

will start ½ hour later each iteration.

Table 9-4: Example AutoCal Sequence

MODE AND

ATTRIBUTE

VALUE COMMENT

SEQUENCE

2

Define Sequence #2

MODE

ZERO-SPAN

Select Zero and

Span Mode

TIMER ENABLE

ON

Enable the timer

STARTING DATE

Sept. 4, 2008

Start after

Sept 4, 2008

STARTING TIME

14:15

First Span starts at

2:15 PM

DELTA DAYS

2

Do Sequence #2

every other day

DELTA TIME

00:30

Do Sequence #2 ½

hr later each day

DURATION

30.0

Operate Span valve

for 15 min

CALIBRATE

ON

Calibrate at end of

Sequence

IMPORTANT

IMPACT ON READINGS OR DATA

The programmed STARTING_TIME must be a minimum of 5 minutes later

than the real time clock for setting real time clock (See Section 5.6.4).

Avoid setting two or more sequences at the same time of the day. Any

new sequence that is initiated whether from a timer, the COM ports or the

contact closure inputs will override any sequence that is in progress.

IMPORTANT

IMPACT ON READINGS OR DATA

With CALIBRATE turned ON, the state of the internal setup variables

DYN_SPAN and DYN_ZERO is set to ON and the instrument will reset the

slope and offset values for the CO response each time the AutoCal

program runs.

This continuous readjustment of calibration parameters can often mask

subtle fault conditions in the analyzer. It is recommended that, if

CALIBRATE is enabled, the analyzer’s test functions, slope and offset

values be checked frequently to assure high quality and accurate data

from the instrument.

06864B DCN6314