71

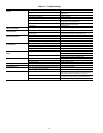

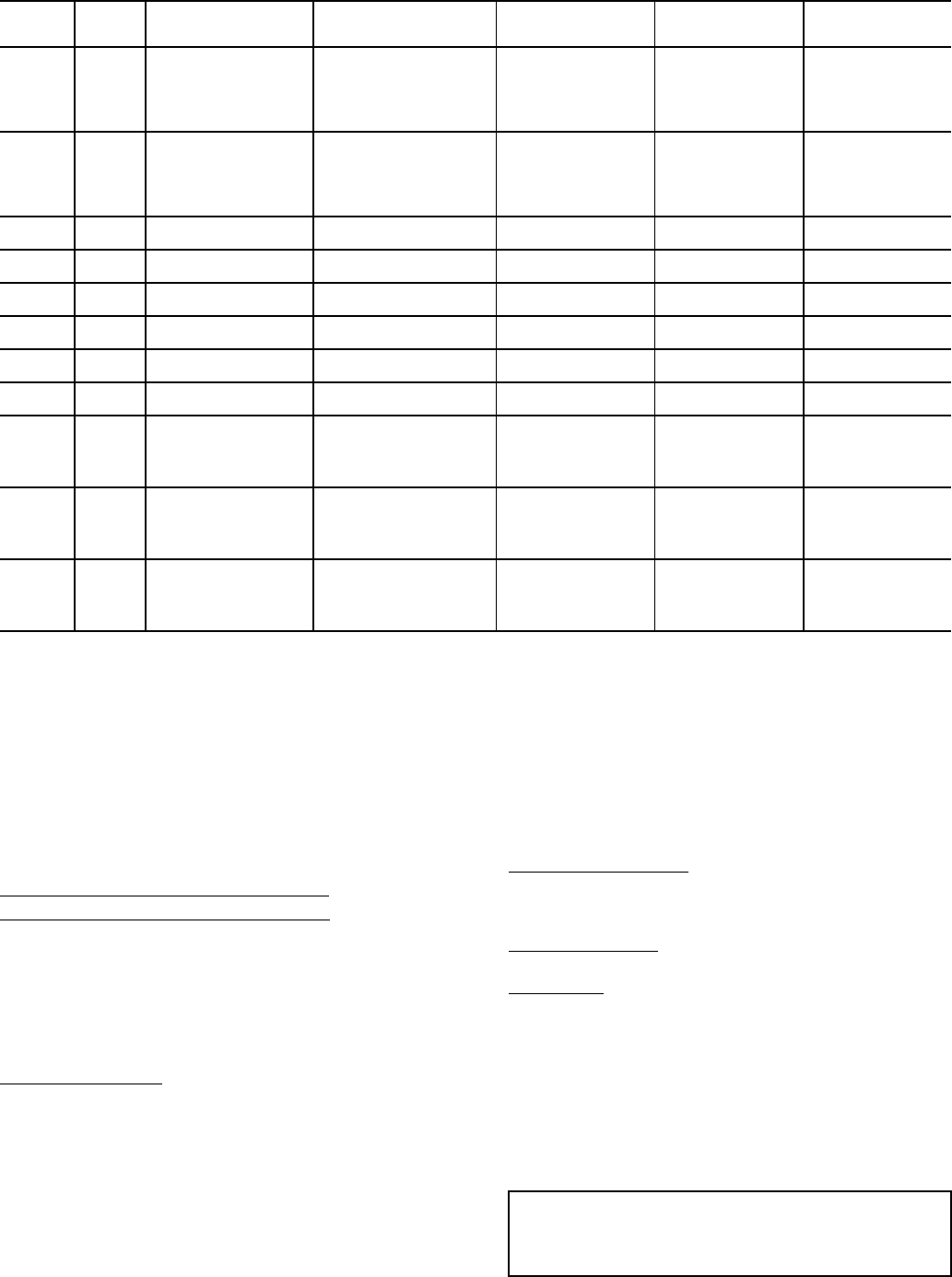

Table 42 — Alarm and Alert Codes (cont)

LEGEND FOR TABLE 42

COMPRESSOR FAILURE ALERTS

T051, T052 (Circuit A Compresser Failures)

T055, T056 (Circuit B Compressor Failures) — Alert codes

051, 052, 055, and 056 are for compressors A1, A2, B1, and

B2 respectively. These alerts occur when the current sensor

(CS) does not detect compressor current during compressor op-

eration. When this occurs, the control turns off the compressor.

If the current sensor board reads OFF while the compressor

relay has been commanded ON, an alert is generated.

POSSIBLE CAUSES

Compressor Overload

— Either the compressor internal over-

load protector is open or the external overload protector (Kri-

wan module) has activated. The external overload protector

modules are mounted in the compressor wiring junction box.

Temperature sensors embedded in the compressor motor wind-

ings are the inputs to the module. The module is powered with

24 vac from the units main control box. The module output is a

normally closed contact that is wired in series with the com-

pressor contactor coil. In a compressor motor overload condi-

tion, contact opens, deenergizing the compressor contactor.

Low Refrigerant Charge

— If the compressor operates for an

extended period of time with low refrigerant charge, the com-

pressor ASTP device will open, which will cause the compres-

sor to trip on its overload protection device.

Circuit Breaker Trip

— The compressors are protected from

short circuit by a breaker in the control box.

Wiring Error

— A wiring error might not allow the compres-

sor to start.

To check out alerts T051-T056:

1. Turn on the compressor in question using Service Test

mode. If the compressor does not start, then most likely

the problem is one of the following: HPS open, open in-

ternal protection, circuit breaker trip, incorrect safety wir-

ing, or incorrect compressor wiring.

2. If the compressor does start, verify it is rotating in the cor-

rect direction.

ALARM/

ALERT

CODE

ALARM

OR

ALERT

DESCRIPTION

WHY WAS THIS

ALARM

GENERATED?

ACTION TAKEN

BY CONTROL

RESET

METHOD

PROBABLE

CAUSE

T302 Alert

Strainer Blowdown

Scheduled

Maintenance Due

Strainer Service

Countdown (S.T.DN)

expired. Complete strainer

blowdown and enter 'YES'

for Strainer Maintenance

Done (S.T.MN) item.

None Automatic

Routine strainer

maintenance

required

T303 Alert

Condenser Coil

Maintenance Due

Coil Service Countdown

(C.L.DN) expired.

Complete condenser coil

cleaning and enter 'YES'

for Coil Maintenance Done

(C.L.MN) item.

None Automatic

Routine condenser

coil maintenance

required

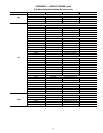

T500 Alert

Current Sensor Board

A1 Failure

Alert occurs when CSB out-

put is a constant high value

Compressor A1 shut

down

Automatic

CSB failure.

Wiring error.

T501 Alert

Current Sensor Board

A2 Failure

Alert occurs when CSB out-

put is a constant high value

Compressor A2 shut

down

Automatic

CSB failure.

Wiring error.

T502 Alert

Current Sensor Board

A3 Failure

Alert occurs when CSB out-

put is a constant high value

Compressor A3 shut

down

Automatic

CSB failure.

Wiring error.

T503 Alert

Current Sensor Board

B1 Failure

Alert occurs when CSB out-

put is a constant high value

Compressor B1 shut

down

Automatic

CSB failure.

Wiring error.

T504 Alert

Current Sensor Board

B2 Failure

Alert occurs when CSB out-

put is a constant high value

Compressor B2 shut

down

Automatic

CSB failure.

Wiring error.

T505 Alert

Current Sensor Board

B3 Failure

Alert occurs when CSB out-

put is a constant high value

Compressor B3 shut

down

Automatic

CSB failure.

Wiring error.

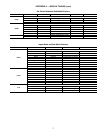

T950 Alert Loss of Communication

with Water System

Manager

No communications have

been received by the MBB

within 5 minutes of last

transmission

WSM forces removed.

Chiller runs under own

control

Automatic Failed module, wiring

error, failed

transformer, loose

connection plug,

wrong address

T951 Alert Loss of Communication

with Chillervisor System

Manager

No communications have

been received by the MBB

within 5 minutes of last

transmission

CSM forces removed.

Chiller runs under own

control

Automatic Failed module, wiring

error, failed

transformer, loose

connection plug,

wrong address

T952 Alert Loss of Communication

with Hydronic System

Manager

No communications have

been received by the MBB

within 5 minutes of last

transmission

HSM forces removed.

Chiller runs under own

control

Automatic Failed module, wiring

error, failed

transformer, loose

connection plug,

wrong address

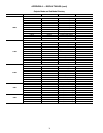

CCN — Carrier Comfort Network

CSB — Current Sensor Board

EEPROM — Electronic Eraseable Programmable Read Only Memory

EMM — Energy Management Module

EWT — Entering Fluid Temperature

EXV — Electronic Expansion Valve

HSM — Hydronic System Manager

LCW — Leaving Chilled Water

LWT — Leaving Fluid Temperature

MBB — Main Base Board

OAT — Outdoor-Air Temperature

SCT — Saturated Condensing Temperature

WSM — Water System Manager

IMPORTANT: Prolonged operation in the wrong direction

can damage the compressor. Correct rotation can be veri-

fied by a gage set and looking for a differential pressure

rise on start-up.