68

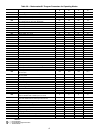

Table 42 — Alarm and Alert Codes (cont)

ALARM/

ALERT

CODE

ALARM

OR

ALERT

DESCRIPTION

WHY WAS THIS

ALARM

GENERATED?

ACTION TAKEN

BY CONTROL

RESET

METHOD

PROBABLE

CAUSE

T110 Alert Circuit A Loss of Charge

If the compressors are off

and discharge pressure

reading is < 26 psig for

30 sec.

Circuit not allowed to

start.

Manual

Refrigerant leak or

transducer failure

T111 Alert Circuit B Loss of Charge

If the compressors are off

and discharge pressure

reading is < 26 psig for

30 sec.

Circuit not allowed to

start.

Manual

Refrigerant leak or

transducer failure

T112 Alert

Circuit A High Saturated

Suction Temperature

Circuit saturated suction

temperature pressure

transducer > 70 F (21.1 C)

for 5 minutes

Circuit shut down Manual

Faulty Expansion valve,

faulty suction pressure

transducer or high entering

fluid temperature.

T113 Alert

Circuit B High Saturated

Suction Temperature

Circuit saturated suction

temperature pressure

transducer > 70 F (21.1 C)

for 5 minutes

Circuit shut down Manual

Faulty Expansion valve,

faulty suction pressure

transducer or high entering

fluid temperature.

T114 Alert

Circuit A Low Suction

Superheat

Suction superheat is

less than 5° F (2.8 C) for 5

minutes.

Circuit A shut down.

Automatic restart

after first daily

occurrence.

Manual restart

thereafter.

Faulty expansion valve,

faulty suction pressure

transducer, faulty suction gas

thermistor, circuit

overcharged

T115 Alert

Circuit B Low Suction

Superheat

Suction superheat is

less than 5° F (2.8 C) for 5

minutes.

Circuit B shut down.

Automatic restart

after first daily

occurrence.

Manual restart

thereafter.

Faulty expansion valve,

faulty suction pressure

transducer, faulty suction

gas thermistor, circuit

overcharged

T116 Alert

Circuit A Low Cooler

Suction Temperature

Mode 7 caused the com-

pressor to unload 6 consecu-

tive times with less than a

30-minute interval between

each circuit shutdown.

Circuit shut down Manual

Faulty expansion valve, low

refrigerant charge, plugged

filter drier, faulty suction

pressure transducer, low

cooler fluid flow

T117 Alert

Circuit B Low Cooler

Suction Temperature

Mode 8 caused the com-

pressor to unload 6 consecu-

tive times with less than a

30-minute interval between

each circuit shutdown.

Circuit shut down Manual

Faulty expansion valve, low

refrigerant charge, plugged

filter drier, faulty suction

pressure transducer, low

cooler fluid flow

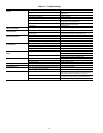

T118 Alert

High Discharge Gas

Temperature Alert

Discharge Thermistor (DTT)

reading is greater than 250 F

Compressor A1 shut

down

Automatic

Refrigerant charge, plugged

filter drier, head pressure

control.

A118 Alarm

High Discharge Gas

Temperature

3 Discharge Gas Tempera-

ture alarms occur within a

day

Compressor A1 shut

down

Manual

Refrigerant charge, plugged

filter drier, head pressure

control.

T126 Alert

Circuit A High

Discharge Pressure

Compressor operation out-

side of operating envelope.

Circuit shut down

Automatic, only

after first 3 daily

occurrences.

Manual reset

thereafter. Read-

ing from OAT sen-

sor must drop 5 F

(2.8 C) before

restart

Faulty transducer/high

pressure switch, low/

restricted condenser

airflow

T127 Alert

Circuit B High

Discharge Pressure

Compressor operation out-

side of operating envelope.

Circuit shut down

Automatic, only

after first 3 daily

occurrences. Man-

ual reset thereafter.

Reading from OAT

sensor must drop

5 F (2.8 C) before

restart

Faulty transducer/high

pressure switch, low/

restricted condenser

airflow

T133 Alert

Circuit A Low Suction

Pressure

Suction pressure below

34 psig for 8 seconds or

below 23 psig

Circuit shut down

Automatic

restart after first

daily occurrence.

Manual restart

thereafter.

Faulty or sticking EXV, low

refrigerant charge, plugged

filter drier.

T134 Alert

Circuit B Low Suction

Pressure

Suction pressure below

34 psig for 8 seconds or

below 23 psig

Circuit shut down

Automatic

restart after first

daily occurrence.

Manual restart

thereafter.

Faulty or sticking EXV, low

refrigerant charge, plugged

filter drier.

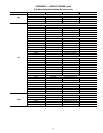

A140 Alert

Reverse Rotation

Detected

Incoming chiller power leads

not phased correctly

Chiller not allowed to

start.

Manual

Reverse any two incoming

power leads to correct. Check

for correct fan rotation first.

A150 Alarm Emergency Stop

CCN emergency stop

command received

Chiller shutdown

without going through

pumpdown.

Automatic once

CCN command for

EMSTOP returns to

normal

CCN Network

command.

A151 Alarm Illegal Configuration

One or more illegal

configurations exists.

Chiller is not allowed to

start.

Manual once

configuration errors

are corrected

Configuration error.

Check unit settings.

A152 Alarm

Unit Down Due to

Failure

Both circuits are down due

to alarms/alerts.

Chiller is unable

to run.

Automatic once

alarms/alerts are

cleared that pre-

vent the chiller from

starting.

Alarm notifies user

that chiller is 100%

down.