44

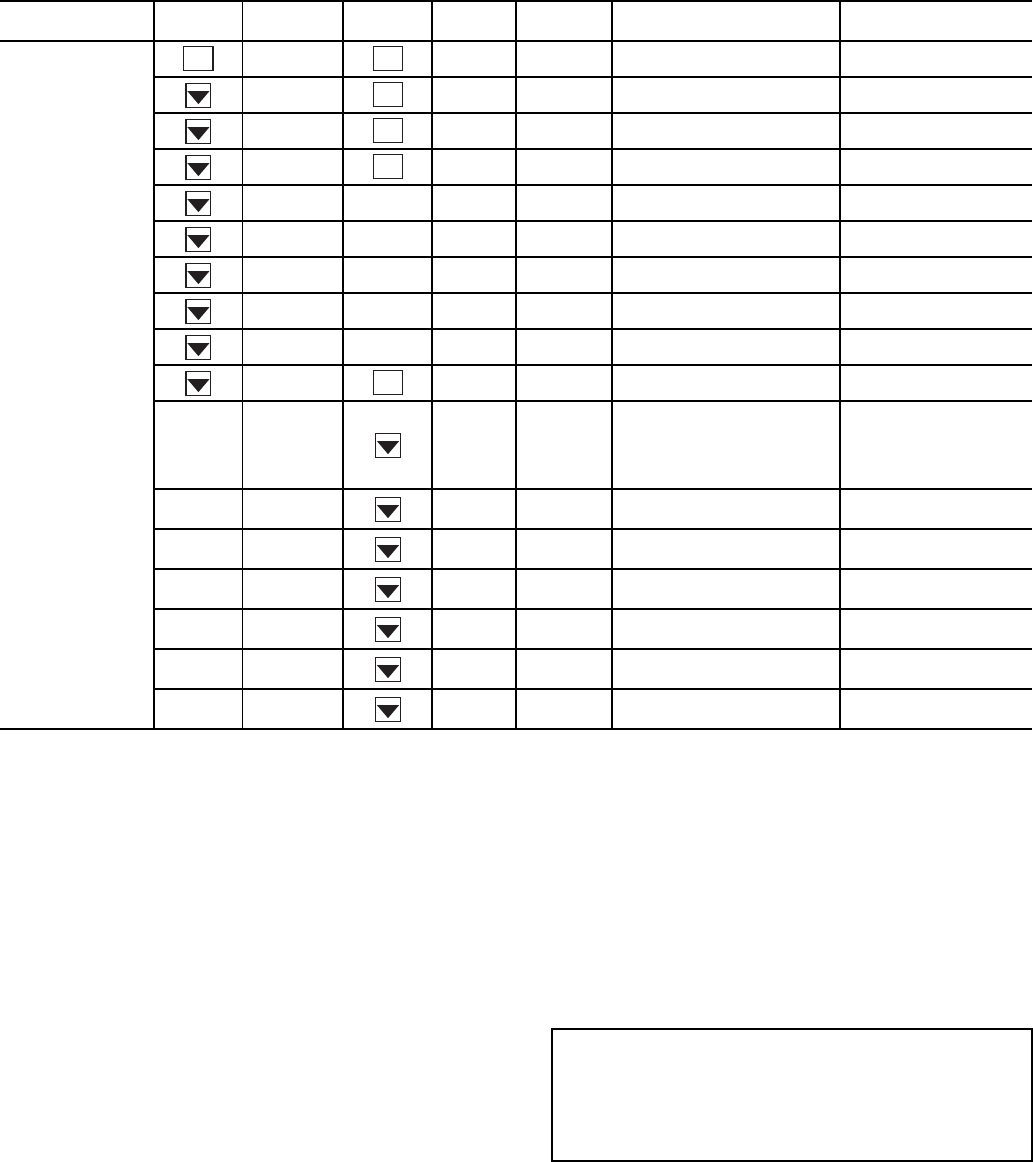

Table 27 — Configuring Demand Limit

*Seven items skipped in this example.

Digital Scroll Option — The 30RAP units have a

factory-installed option for a digital scroll compressor which

provides additional stages of unloading for the unit. The digital

compressor is always installed in the A1 compressor location.

When a digital compressor is installed, a digital unloader sole-

noid (DUS) is used on the digital compressor.

DIGITAL SCROLL OPERATION — A digital scroll oper-

ates in two stages - the "loaded state" when the solenoid valve

is normally closed and the "unloaded state" when the solenoid

valve is open. During the loaded state, the compressor operates

like a standard scroll and delivers full capacity and mass flow.

However, during the unloaded state, there is no capacity

and no mass flow through the compressor. The capacity of the

system is varied by varying the time the compressor operates

in an unloaded and loaded state during a 15-second period. If

the DUS is energized for 7 seconds, the compressor will be

operating at 47% capacity. If the DUS is energized for 10 sec-

onds, the compressor will be operating at approximately 33%

of its capacity. Capacity is the time averaged summation of

loaded and unloaded states, and its range is continuous from

the minimum configured capacity to 100%. Regardless of

capacity, the compressor always rotates with constant speed.

As the compressor transitions from a loaded to unloaded state,

the discharge and suction pressures will fluctuate and the com-

pressor sound will change.

The ComfortLink controller controls and integrates the op-

eration of the DUS into the compressor staging routine to

maintain temperature control. When a digital compressor is in-

stalled, an additional discharge gas temperature thermistor

(DTT) is installed along with the AUX board for control of the

DUS.

DIGITAL COMPRESSOR CONFIGURATION — When a

digital compressor is installed, the configuration parameter

(Configuration

UNIT

A1TY) is configured to YES.

There is also a maximum unload time configuration, (Config-

uration

UNIT

MAX.T) that is set to 7 seconds, which in-

dicates the maximum unloading for the digital compressor is

47%. This is done to optimize efficiency of the system.

PRE-START-UP

Do not attempt to start the chiller until following checks

have been completed.

System Check

1. Check all auxiliary components, such as chilled fluid

pumps, air-handling equipment, or other equipment to

which the chiller supplies liquid. Consult manufacturer's

instructions. Verify that any pump interlock contacts have

been properly installed. If the unit If the unit has

field-installed accessories, be sure all are properly in-

stalled and wired correctly. Refer to unit wiring diagrams.

MODE

KEYPAD

ENTRY

SUB-MODE

KEYPAD

ENTRY

ITEM DISPLAY ITEM EXPANSION COMMENT

CONFIGURATION

DISP TEST ON/OFF Test Display LEDs

UNIT TYPE X Unit Type

OPT1 FLUD X Cooler Fluid

OPT2 CTRL X Control Method

HP.A

HP.B

EXV.A

EXV.B

M.MST

RSET CRST X Cooling Reset Type

DMDC* X Demand Limit Select

Default: 0

0 = None

1 = Switch

2 = 4 to 20 mA Input

3 = CCN Loadshed

DM20 XXX % Demand Limit at 20 mA

Default: 100%

Range: 0 to 100

SHNM XXX

Loadshed Group

Number

Default: 0

Range: 0 to 99

SHDL XXX%

Loadshed Demand

Delta

Default: 0%

Range: 0 to 60%

SHTM XXX MIN

Maximum Loadshed

Time

Default: 60 min.

Range: 0 to 120 min.

DLS1 XXX %

Demand Limit

Switch 1

Default: 80%

Range: 0 to 100%

DLS2 XXX %

Demand Limit

Switch 2

Default: 50%

Range: 0 to 100%

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

complete Start-Up Checklist for 30RAP Liquid Chiller at

end of this publication (pages CL-1 to CL-10). The check-

list assures proper start-up of a unit, and provides a record

of unit condition, application requirements, system infor-

mation, and operation at initial start-up.