30

LEAD/LAG DETERMINATION — This is a configurable

choice and is factory set to be automatic for all units unless the

unit is equipped with a digital scroll compressor or minimum

load, then circuit A is lead (Configuration

OPT2

LLCS).

The value can be changed to Circuit A or Circuit B leading as

desired. Set at automatic, the control will sum the current num-

ber of logged circuit starts and one-quarter of the current oper-

ating hours for each circuit. The circuit with the lowest sum is

started first. Changes to which circuit is the lead circuit and

which is the lag are also made when total machine capacity is

at 100% or when there is a change in the direction of capacity

(increase or decrease) and each circuit’s capacity is equal.

CAPACITY CONTROL OVERRIDES — The following over-

rides will modify the normal operation of the routine.

Deadband Multiplier

— The user configurable Deadband

Multiplier (Configuration

SLCT

Z.GN) has a default val-

ue of 1.0. The range is from 1.0 to 4.0. When set to other than

1.0, this factor is applied to the capacity Load/Unload Factor.

The larger this value is set, the longer the control will delay be-

tween adding or removing stages of capacity. Figure 13 shows

how compressor starts can be reduced over time if the leaving

water temperature is allowed to drift a larger amount above and

below the set point. This value should be set in the range of 3.0

to 4.0 for systems with small loop volumes.

First Stage Override

— If the current capacity stage is zero,

the control will modify the routine with a 1.2 factor on adding

the first stage to reduce cycling. This factor is also applied

when the control is attempting to remove the last stage of

capacity.

Slow Change Override

— The control prevents the capacity

stages from being changed when the leaving fluid temperature

is close to the set point (within an adjustable deadband) and

moving towards the set point.

Ramp Loading

— Ramp loading (Configura-

tion

SLCT

CRMP) limits the rate of change of leaving

fluid temperature. If the unit is in a Cooling mode and config-

ured for Ramp Loading, the control makes 2 comparisons be-

fore deciding to change stages of capacity. The control calcu-

lates a temperature difference between the control point and

leaving fluid temperature. If the difference is greater than 4° F

(2.2° C) and the rate of change (°F or °C per minute) is more

than the configured Cooling Ramp Loading value (CRMP),

the control does not allow any changes to the current stage of

capacity.

Low Entering Fluid Temperature Unloading

— When the

entering fluid temperature is below the control point, the

control will attempt to remove 25% of the current stages being

used. If exactly 25% cannot be removed, the control removes

an amount greater than 25% but no more than necessary. The

lowest stage will not be removed.

Minimum Load Control

— If equipped, the minimum load

control valve is energized only when one compressor is run-

ning on circuit A. If the close control feature is enabled the

minimum load control valve may be used as needed to obtain

leaving fluid temperature close to set point.

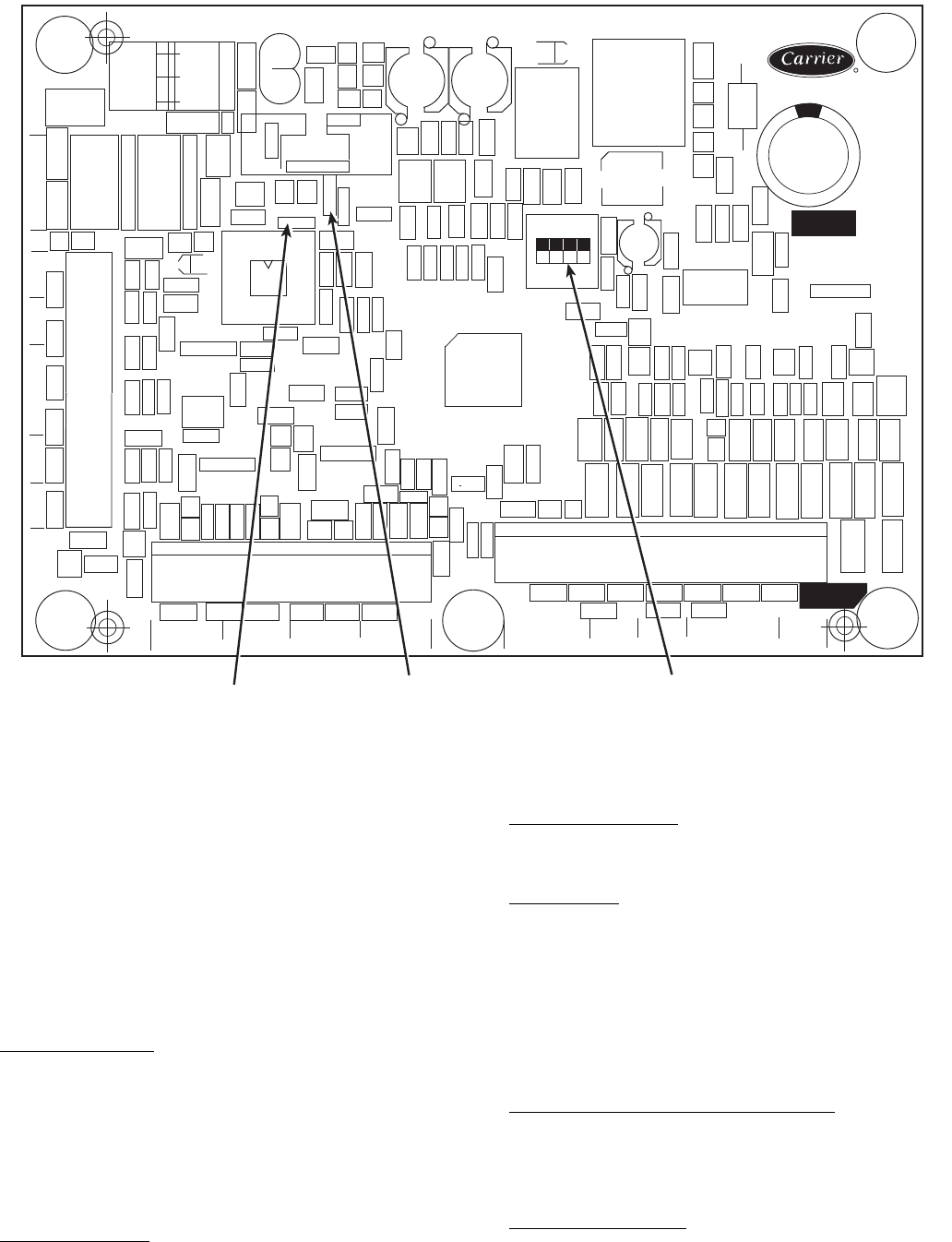

CEBD430351-0396-01C

TEST 1

CEPL130351-01

PWR

TEST 2

J1

J2

J4 J3

J5

J6

J7

LEN

STATUS

RED LED - STATUS

GREEN LED -

LEN (LOCAL EQUIPMENT NETWORK)

ADDRESS

DIP SWITCH

Fig. 12 — Energy Management Module