58

LOW SOUND FAN — A shroud and a wire guard provide

protection from the rotating fan. The exposed end of the fan

motor shaft is protected from weather by grease. If fan motor

must be removed for service or replacement, be sure to re-

grease fan shaft and reinstall fan guard. The fan motor has a

step in the motor shaft. For proper performance, fan should be

positioned such that it is securely seated on this step. Tighten

the bolt to 15 ± 1 ft-lb (20 ± 1.3 N·m).

Motormaster

®

V Controller — The Motormaster V

controller is standard on size 010 and 015 units. For other sizes,

the optional or accessory Motormaster V controller uses an in-

put signal from the AUX board. See Fig. 32. The controller is

factory configured and requires no field programming. If a situ-

ation arises where the drive does not function properly, the in-

formation provided below and in Table 38 can be used to trou-

bleshoot the drive.

GENERAL OPERATION — The speed varies in proportion

to a 4 to 20 mA signal produced by the ComfortLink™ con-

trols. The MMV output speed is displayed in Hz.

The ComfortLink controls must be configured for MMV

operation in order for it to operate. This is configured under the

Configuration menu (Configuration

MM

MMR.S) and

26

25

24

23

22

17

16

15

14

13

12

11

10

9

8

7

6

3

1

3

1

3

1

6

2

4

2

4

2

12

11

21

20

19

18

10

9

8

7

6

5

4

5

4

3

2

1

4

2

1

3

5

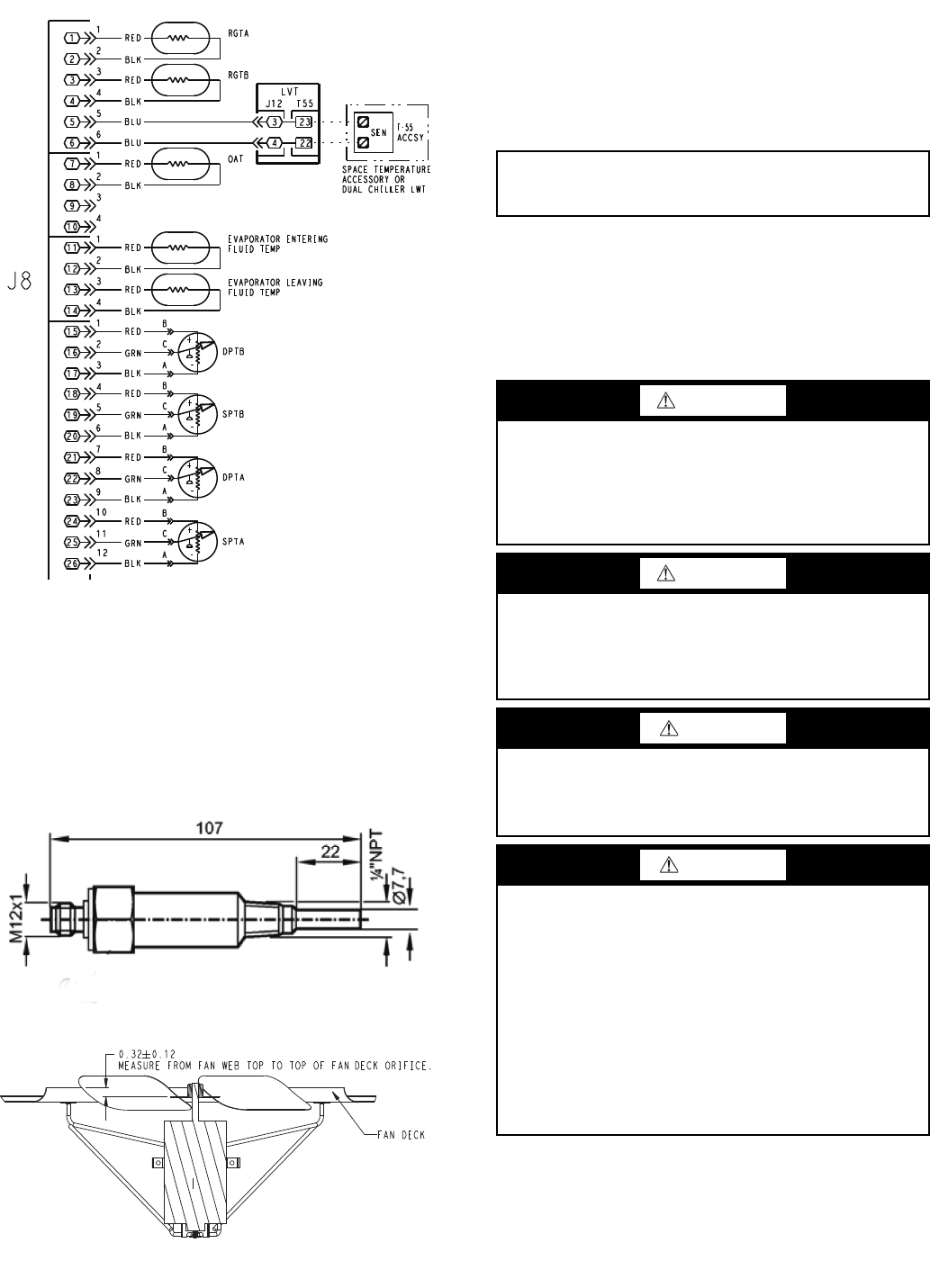

J8

BLK

RED

LVT

4

3

22

23

T-55

ACCSY

SEN

OAT

BLU

BLU

BLK

RED

RGTB

BLK

RED

RGTA

SPTB

-

+

DPTB

-

+

A

C

B

A

C

B

GRN

RED

BLK

GRN

RED

BLK

SPTA

-

+

DPTA

-

+

A

C

B

A

C

B

GRN

RED

BLK

GRN

RED

BLK

BLK

RED

EVAPORATOR ENTERING

FLUID TEMP

BLK

RED

EVAPORATOR LEAVING

FLUID TEMP

SPACE TEMPERATURE

ACCESSORY OR

DUAL CHILLER LWT

J12 T55

Fig. 29 — Thermistor Connections to

Main Base Board, J8 Connector

LEGEND

ACCSY — Accessory

DPT — Discharge Pressure Transducer

LWT — Leaving Water Temperature Sensor

LVT — Low Voltage Terminal

OAT — Outdoor Air Temperature Sensor

RGT — Return Gas Temperature Sensor

SEN — Sensor Terminal Block

SPT — Space Temperature Sensor

a30-4975

Fig. 30 — Chilled Water Flow Switch

a30-499

Fig. 31 — Mounted Fan Position

a30-4976

IMPORTANT: Check for proper fan rotation (counter-

clockwise when viewed from above). If necessary, switch

any 2 power leads to reverse fan rotation.

WARNING

Hazard of electrical shock. Wait three minutes after discon-

necting incoming power before servicing drive. Capacitors

retain charge after power is removed. Drive assembly

includes externally mounted current limiting resistors. Use

extreme caution when servicing the drive. Failure to com-

ply could result in possible personal injury.

WARNING

When configured as shown in this literature, this equip-

ment is designed to start when it receives line power.

Ensure that all personnel are clear of fans and guards are

installed before applying power. Failure to comply could

result in possible personal injury.

CAUTION

DO NOT connect incoming AC power to output terminals

T1, T2, and T3. Severe damage to the drive will result. Do

not continuously cycle input power to the drive more than

once every two minutes. Damage to the drive will result.

CAUTION

If input power has not been applied to the drive for a period

of time exceeding three years (due to storage, etc.), the

electrolytic DC bus capacitors within the drive can change

internally, resulting in excessive leakage current. This can

result in premature failure of the capacitors if the drive is

operated after such a long period of inactivity or storage. In

order to reform the capacitors and prepare the drive for

operation after a long period of inactivity, apply input

power to the drive for 8 hours prior to actually operating

the motor. Before attempting to operate the drive, motor,

and driven equipment, be sure all procedures pertaining to

installation and wiring have been properly followed. Fail-

ure to comply could result in equipment damage.