48

During the next several seconds, carefully connect the nega-

tive test lead to pins 1,2,4 and 5 in succession (plug J6 for Cir-

cuit A, plug J7 for Circuit B). Digital voltmeters will average

this signal and display approximately 6 vdc. If it remains con-

stant at a voltage other than 6 VDC or shows 0 volts, remove

the connector to the valve and recheck.

Press and select 0% to close the valve. Check the 4 po-

sition DIP switch on the board (all switches should be set to

On). If a problem still exists, replace the EXV module. If the

reading is correct, the expansion valve and EXV wiring should

be checked. Check the EXV terminal strip and interconnecting

wiring.

1. Check color coding and wire connections. Make sure

they are connected to the correct terminals at the EXV

driver and EXV plug and that the cables are not crossed.

2. Check for continuity and tight connection at all pin

terminals.

3. Check the resistance of the EXV motor windings. Re-

move the EXV module plug (J6 for Circuit A, J7 for Cir-

cuit B) and check the resistance of the two windings be-

tween pins 1 and 2 for one winding and pins 4 and 5 for

the other winding (see Fig. 25). The resistance should be

100 ohms ± 10 ohms.

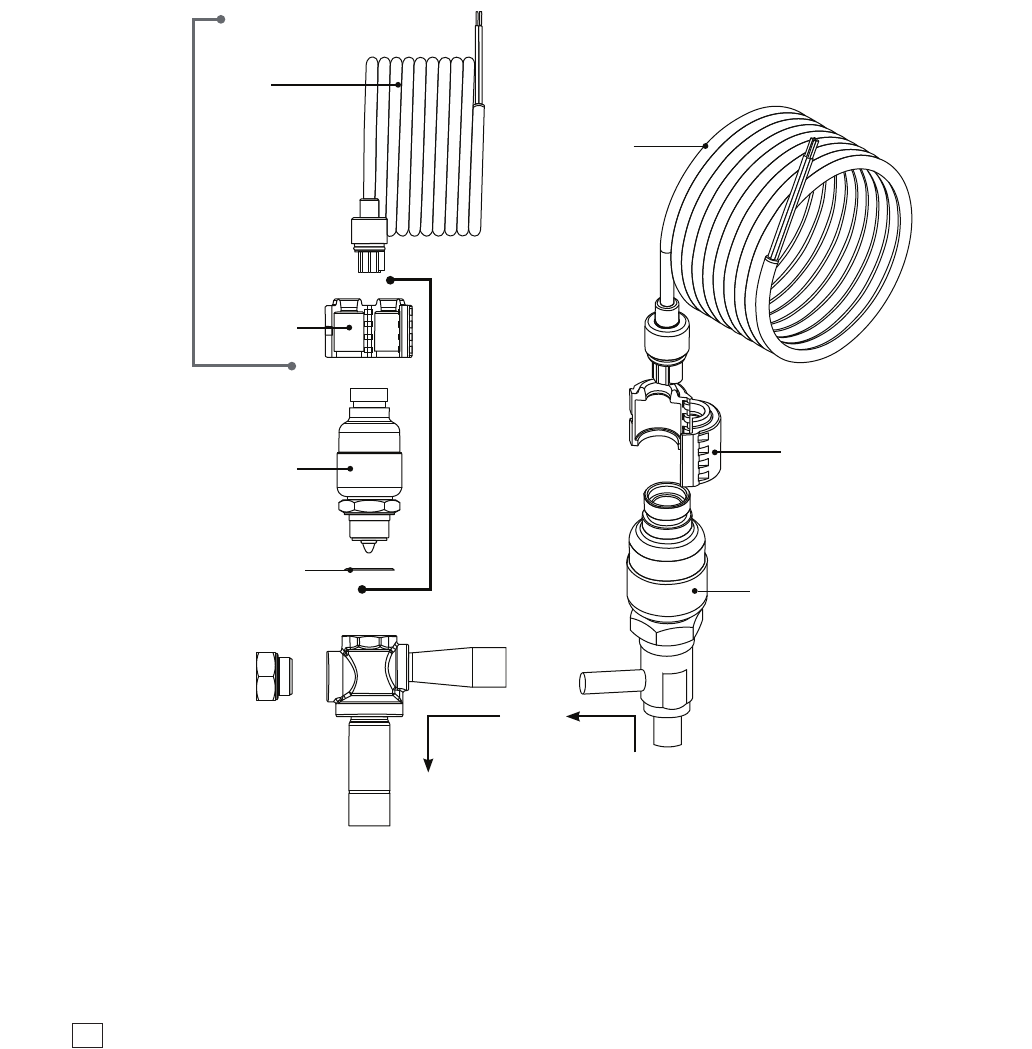

FIELD SERVICING INSTRUCTIONS — The EXV valves

on sizes 025, 030, 050-060 can be serviced. The EXV valves

on all other sizes are hermetic and cannot be disassembled for

installation or during service, however, the cable and retainer

may be replaced if necessary. Motor kits for the EXV valve are

available as replacement parts.

To remove the valve from the system, perform the follow-

ing procedure:

1. Be sure the refrigerant has been recovered from the

circuit.

2. Disconnect the line voltage to the valve controller. Dis-

connect the valve wires from the controller.

3. If the motor fails to operate properly, check the resistance

of each motor phase. Resistance between black and white

leads or between the red and green leads should be ap-

proximately 100 ohms. Differences of more than 10% be-

tween phases indicate a defective motor. Resistance be-

tween black and red, or any lead and piping, should be in-

finite or “open”. Any resistance reading will indicate a

shorted winding and the valve will need to be replaced.

4. The output of the controller to the valve can be tested

with the following procedure:

a. Disconnect supply voltage to the controller.

SPORLAN

MOTOR AND

ADAPTER

ASSEMBLY

CABLE

CABLE

CABLE RETAINER

CABLE

RETAINER

MOTOR ADAPTER

ASSEMBLY

MOTOR ADAPTER

ASSEMBLY

INCLUDED IN CABLE KIT

GASKET

SIGHTGLASS

FLOW

DIRECTION

NORMAL

FLOW

DIRECTION

Fig. 24 — Electronic Expansion Valve Details

a30-4971

ENTER