65

High-Pressure Switch Trip

— The high pressure switch has

opened. Below are the factory settings for the fixed high pres-

sure switch.

ASTP Protection Trip

— All non-digital Copeland compres-

sors are equipped with an advanced scroll temperature protec-

tion (ASTP). A label located above the terminal box identifies

models that contain this technology. See Fig. 34.

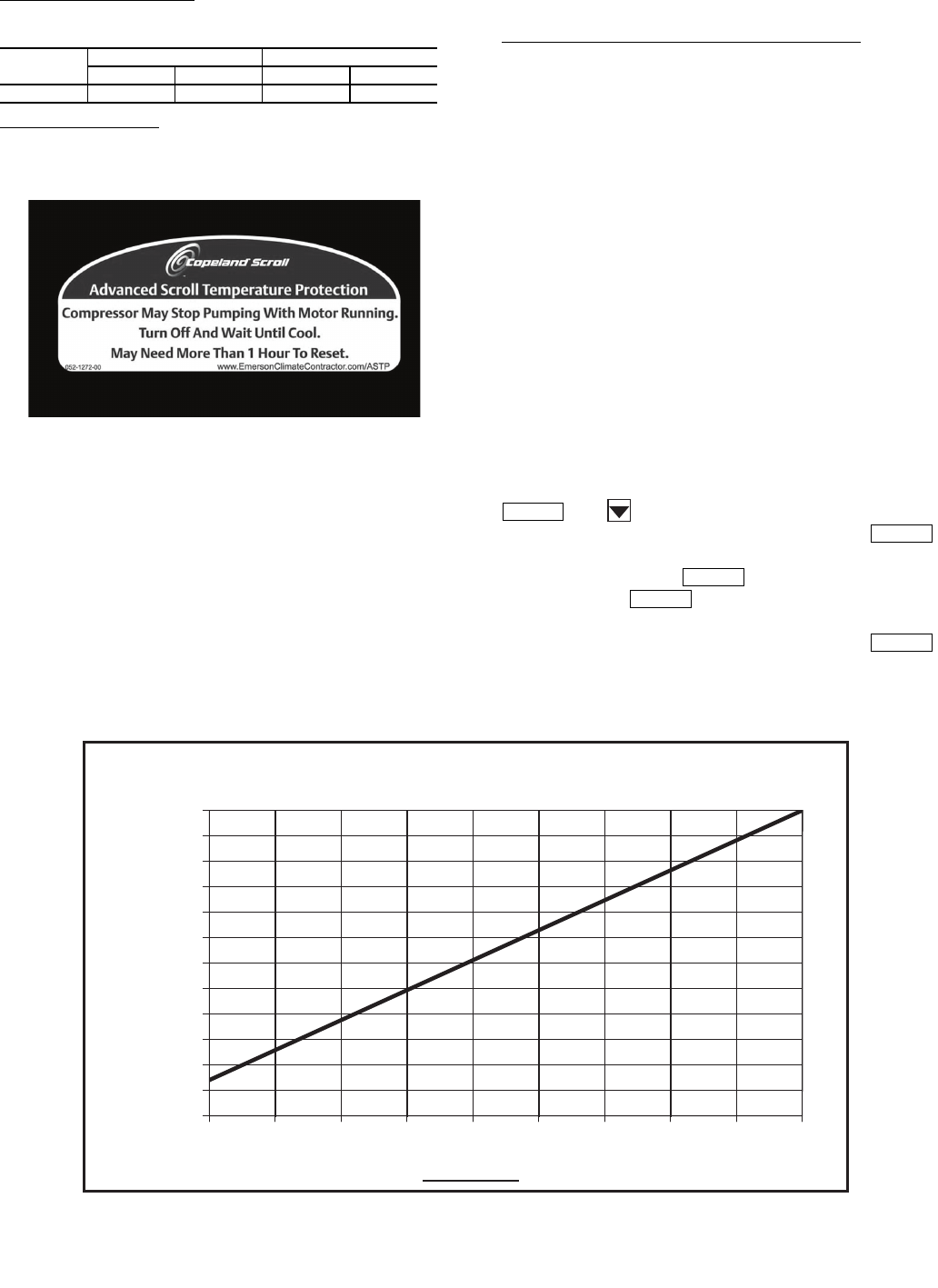

Advanced scroll temperature protection is a form of inter-

nal discharge temperature protection that unloads the scroll

compressor when the internal temperature reaches approxi-

mately 300 F. At this temperature, an internal bi-metal disk

valve opens and causes the scroll elements to separate, which

stops compression. Suction and discharge pressures balance

while the motor continues to run. The longer the compressor

runs unloaded, the longer it must cool before the bi-metal disk

resets. See Fig. 35 for approximate reset times.

To manually reset ASTP, the compressor should be stopped

and allowed to cool. If the compressor is not stopped, the motor

will run until the motor protector trips, which occurs up to

90 minutes later. Advanced scroll temperature protection will

reset automatically before the motor protector resets, which

may take up to 2 hours.

High Discharge Gas Temperature Protection

— Units

equipped with digital compressors have an additional thermis-

tor located on the discharge line, If discharge temperature ex-

ceeds 265 F (129.4 C), the digital compressor will be shut off.

Alarms will also occur if the current sensor board malfunc-

tions or is not properly connected to its assigned digital input. If

the compressor is commanded OFF and the current sensor

reads ON, an alert is generated. This will indicate that a com-

pressor contactor has failed closed. In this case, a special mode,

Compressor Stuck on Control, will be enabled and all other

compressors will be turned off. An alarm will then be enabled

to indicate that service is required. Outdoor fans will continue

to operate. The first outdoor fan stage is turned on immediately.

The other stages of fan will be turned on as required by SCT.

Alarms and Alerts — These are warnings of abnormal

or fault conditions, and may cause either one circuit or the

whole unit to shut down. They are assigned code numbers as

described in Table 42.

Automatic alarms will reset without operator intervention if

the condition corrects itself. The following method must be

used to reset manual alarms:

Before resetting any alarm, first determine the cause of the

alarm and correct it. Enter the Alarms mode indicated by the

LED on the side of the scrolling marquee display. Press

and until the sub-menu item RCRN “RESET

ALL CURRENT ALARMS” is displayed. Press .

The control will prompt the user for a password, by displaying

PASS and WORD. Press to display the default pass-

word, 1111. Press for each character. If the password

has been changed, use the arrow keys to change each individu-

al character. Toggle the display to “YES” and press .

The alarms will be reset.

30RAP UNIT

SIZE

CUTOUT CUT-IN

psig kPa psig kPa

010-060 650 4482 500 3447

Fig. 34 — Advanced Scroll Temperature

Protection Label

ENTER

ENTER

ENTER

ENTER

ENTER

Fig. 35 — Recommended Minimum Cool Down Time After Compressor is Stopped*

0

10

20

30

40

50

60

70

80

90

100

110

120

0 102030405060708090

Compressor Unloaded Run Time (Minutes)

Recommended Cooling Time

(Mi

nut

es)

*Times are approximate.

NOTE: Various factors, including high humidity, high ambient temperature,

and the presence of a sound blanket will increase cool-down times.