124

Operation selection function

2.10.10 PID control (Pr. 88 to Pr. 94 )

<Setting>

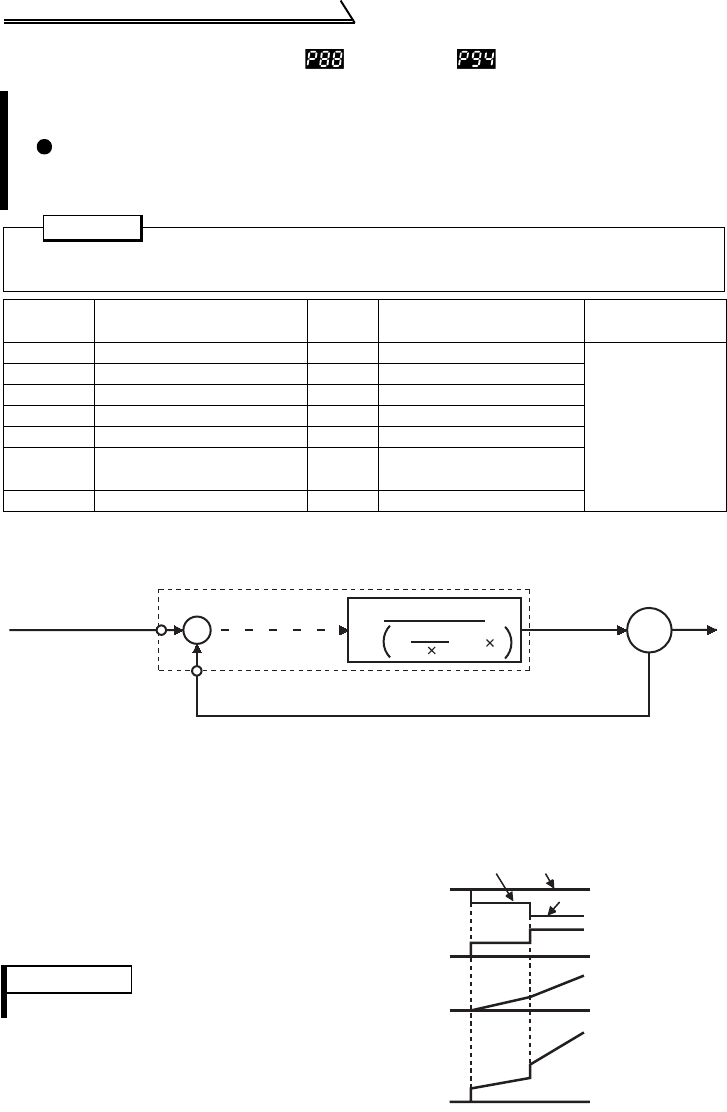

(1) Basic PID control configuration

(2) PID action overview

The inverter can be used to exercise process control, e.g. flow rate, air volume

or pressure.

The voltage input signal (0 to +5V or 0 to +10V) or Pr. 93 setting is used as a

set point and the 4 to 20mADC current input signal used as a feedback value

to constitute a feedback system for PID control.

POINT

Made valid by turning on the X14 signal. Use Pr. 60 to Pr. 63 (input terminal function

selection) to make assignment.

Parameter Name

Factory

Setting

Setting Range Remarks

88 PID action selection 20 20, 21

Setting is enabled

when Pr. 30 = "1"

89 PID proportional band 100% 0.1 to 999%, - - -

90 PID integral time 1s 0.1 to 999s, - - -

91 PID upper limit - - - 0 to 100%, - - -

92 PID lower limit - - - 0 to 100%, - - -

93

PID action set point for PU

operation

0% 0 to 100%

94 PID differential time - - - 0.01 to 10s, - - -

1) PI action

A combination of proportional control

action (P) and integral control action (I)

for providing a manipulated variable in

response to deviation and changes

with time.

[Operation example for stepped

changes of measured value]

REMARKS

PI action is the sum of P and I actions.

+

-

IM

Kp: Proportion constant Ti: Integral time S: Operator Td: Differential time

Set point

Manipulated

variable

Motor

Feedback signal (Measured value)

Inverter circuit :

Ti S

1

1+

+Td S

Kp

PID operation

Terminal 4

Pr. 93 or Terminal 2

Deviation

Set point

Measured value

Time

Time

Time

PI action

I action

P action