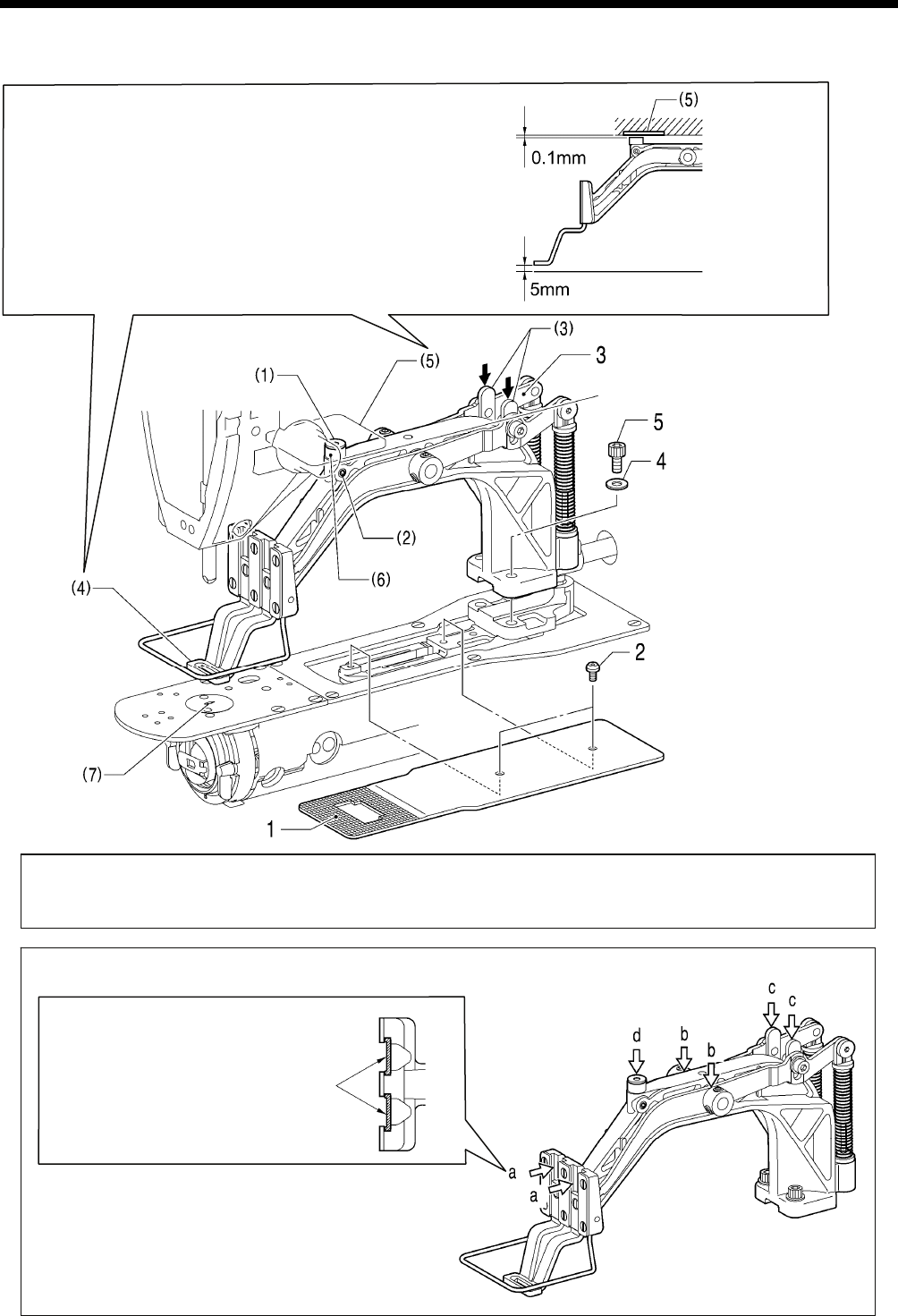

10. ASSEMBLY

KE-430F, BE-438F

100

Apply grease to all sliding parts during assembly.

10-14. Work clamp arm mechanism (KE-430F)

After installing, carry out test feeding and check that the needle hole (7) is not inside the work clamp (4) and the

frame of the feed plate 1. If the needle hole (7) is inside the frame, adjust the position of the work clamp arm

assembly 3 and the feed plate.

2884B

1. Feed plate

2. Screws [2 pcs]

3. Work clamp arm assembly

4. Plain washers [2 pcs]

5. Bolts [2 pcs]

(1) Slider

(2) Set screw

(3) Work clamp arm lever plate

(4) Work clamp

(5) Work clamp arm support plate

(6) Support shaft

(7) Needle hole

2886B

2885B

a. Sliding portion of the work clamp

(Apply small amount of grease.)

b. Sliding portion of the work clamp arm lever shaft

and the work clamp arm levers R and L

c. Round portion of the work clamp arm lever plate

d. Slider of work clamp support shaft

Push the work clamp arm lever plate (3) in the direction

of the arrow to raise the work clamp (4) by about 5

mm, set so that there is a clearance of 0.1 mm

between the underside of the work clamp arm support

plate (5) and the slider (1), and then secure the slider

(1) of the work clamp support shaft (6) with the set

screw (2).

Grease

2887B

It is recommended that you

use commercially-available

SHIN NISSEKI Power

Knock WB2 as the grease

to be applied to the sliding

part of the work clamp.